D.3 UL Standards

The UL/cUL mark applies to products in the United States and Canada. It indicates that UL has performed product

testing and evaluation, and determined that their stringent standards for product safety have been met. For a product to

receive UL certification, all components inside that product must also receive UL certification.

Figure D.6

Figure D.6 UL/cUL Mark

◆ UL Standards Compliance

This drive is tested in accordance with UL standard UL508C and complies with UL requirements. The conditions

described below must be met to maintain compliance when using this drive in combination with other equipment:

■

Installation Area

Do not install the drive to an area greater than pollution severity 2 (UL standard).

■

Main Circuit Terminal Wiring

Cable Connectors

Yaskawa recommends using UL-listed copper wires (rated at 75°C), and closed-loop connectors or CSA-certified ring

connectors sized for the selected wire gauge to maintain proper clearances when wiring the drive. Use the correct crimp

tool to install connectors per manufacturer recommendation. Table D.3 lists a suitable closed-loop connector

manufactured by JST Corporation.

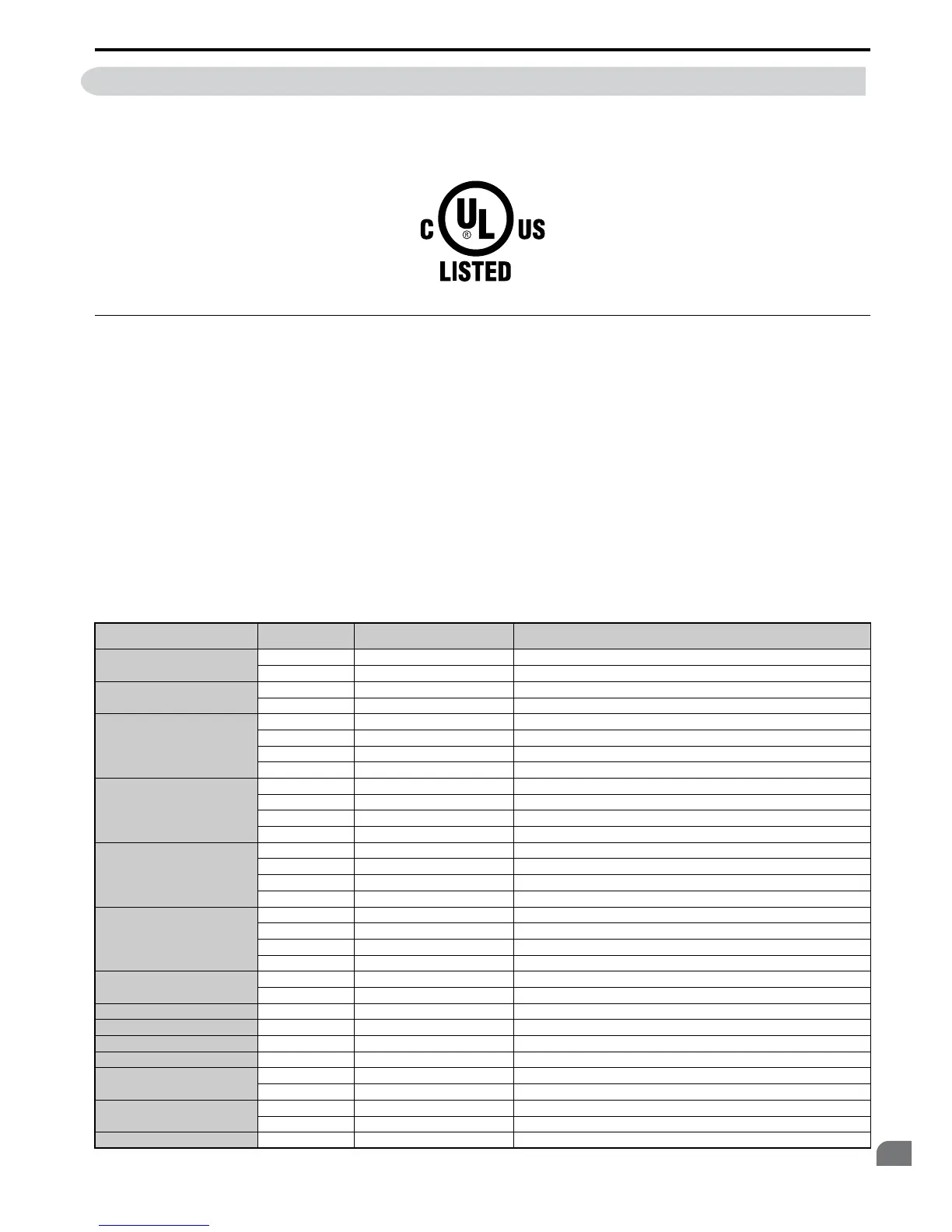

Table D.3 Closed-Loop Crimp Terminal Size (JIS C 2805) (same for 200 V and 400 V)

Wire Gauge

mm

2

(AWG)

Terminal Screws Crimp Terminal Model Numbers

Tightening Torque

Nxm (lbxin.)

0.75 (18)

M3.5 R1.25-3.5 0.8 to 1.0 (7.1 to 8.9)

M4 R1.25-4 1.2 to 1.5 (10.6 to 13.3)

1.25 (16)

M3.5 R1.25-3.5 0.8 to 1.0 (7.1 to 8.9)

M4 R1.25-4 1.2 to 1.5 (10.6 to 13.3)

2 (14)

M3.5 R2-3.5 0.8 to 1.0 (7.1 to 8.9)

M4 R2-4 1.2 to 1.5 (10.6 to 13.3)

M5 R2-5 2.0 to 2.5 (17.7 to 22.1)

M6 R2-6 4.0 to 5.0 (35.4 to 44.3)

3.5/5.5 (12/10)

M4 R5.5-4 1.2 to 1.5 (10.6 to 13.3)

M5 R5.5-5 2.0 to 2.5 (17.7 to 22.1)

M6 R5.5-6 4.0 to 5.0 (35.4 to 44.3)

M8 R5.5-8 9.0 to 11.0 (79.7 to 97.4)

8 (8)

M4 8-4 1.2 to 1.5 (10.6 to 13.3)

M5 R8-5 2.0 to 2.5 (17.7 to 22.1)

M6 R8-6 4.0 to 5.0 (35.4 to 44.3)

M8 R8-8 9.0 to 11.0 (79.7 to 97.4)

14 (6)

M4 14-4

<1> 1.2 to 1.5 (10.6 to 13.3)

M5 R14-5 2.0 to 2.5 (17.7 to 22.1)

M6 R14-6 4.0 to 5.0 (35.4 to 44.3)

M8 R14-8 9.0 to 11.0 (79.7 to 97.4)

22 (4)

M10 R22-10 18.0 to 23.0 (159.0 to 204.0)

M12 R22-12 32.0 to 40.0 (284.0 to 354.0)

30/38 (3/2) M12 R38-12 32.0 to 40.0 (284.0 to 354.0)

50/60 (1/ 1/0) M12 R60-12 32.0 to 40.0 (284.0 to 354.0)

80 (2/0) M12 R80-12 32.0 to 40.0 (284.0 to 354.0)

100 (4/0) M12 R100-12 32.0 to 40.0 (284.0 to 354.0)

150 (250/300MCM)

M10 150-10 18.0 to 23.0 (159.0 to 204.0)

M12 150-12 32.0 to 40.0 (284.0 to 354.0)

200 (400MCM)

M10 200-10 18.0 to 23.0 (159.0 to 204.0)

M12 R200-12 32.0 to 40.0 (284.0 to 354.0)

325 (600/650MCM) M12 325-12 32.0 to 40.0 (284.0 to 354.0)

Loading...

Loading...