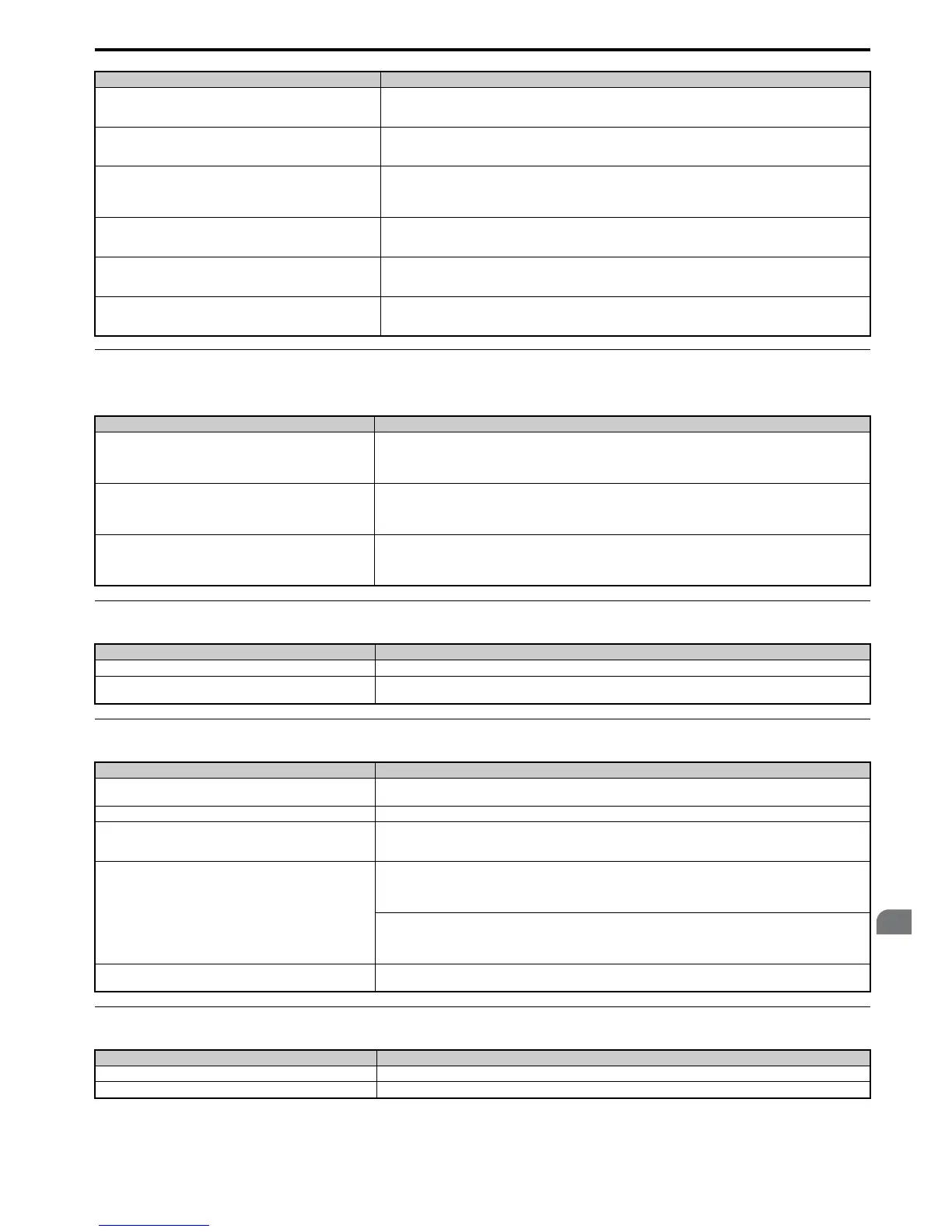

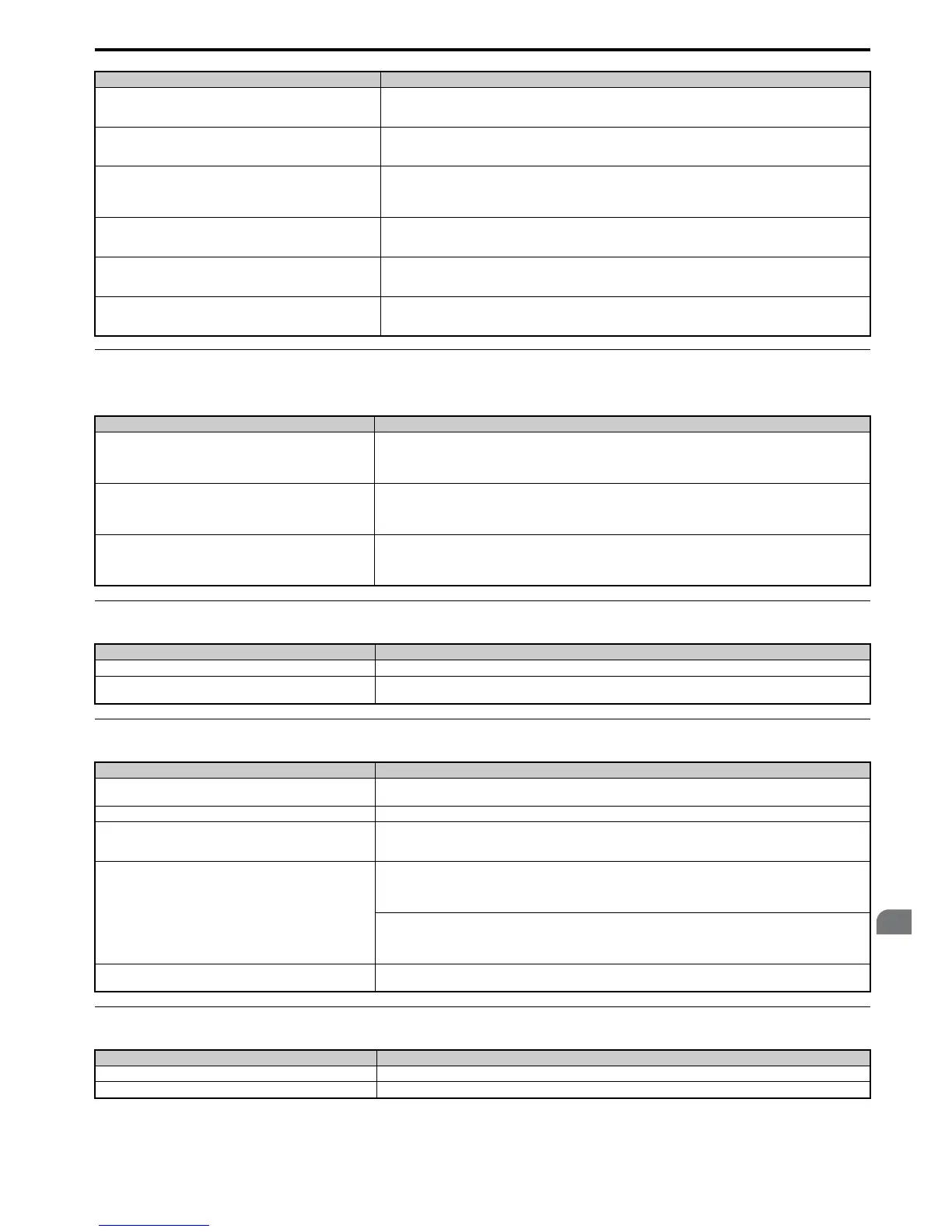

◆ Drive Frequency Reference Differs from the Controller Frequency Reference

Command

◆ Excessive Motor Oscillation and Erratic Rotation

◆ Deceleration Takes Longer Than Expected with Dynamic Braking Enabled

◆ Load Falls When Brake is Applied (Hoist-Type Applications)

Motor characteristics and drive parameter settings are incompatible

with one another.

• Set the correct V/f pattern so that it matches the characteristics of the motor being used.

• Check the V/f pattern set to E1-03.

• Execute Rotational Auto-Tuning.

Although the drive is operating in Open Loop Vector motor control

method, Auto-Tuning has not been performed.

• Perform Auto-Tuning.

• Calculate motor data and reset motor parameters.

• Switch to V/f Control (A1-02 = 0).

Incorrect frequency reference setting.

• Check the multi-function analog input settings. Multi-function analog input terminal A1, A2, or A3 is set for

frequency gain (H3-02, H3-10, or H3-06 is set to “1”), but there is no voltage or current input provided.

• Make sure H3-02, H3-10, and H3-06 are set to the proper values.

• See if the analog input value is set to the right value (U1-13 to U1-15).

The Stall Prevention level during acceleration and deceleration set

too low.

• Check the Stall Prevention level during acceleration (L3-02).

• If L3-02 is set too low, acceleration may be taking too long.

• Increase L3-02.

The Stall Prevention level during run has been set too low.

• Check the Stall Prevention level during run (L3-06).

• If L3-06 is set too low, speed will drop as the drive outputs torque.

• Increase the setting value.

Drive reached the limitations of the V/f motor control method.

• The motor cable may be long enough (over 50 m) to require Auto-Tuning for line-to-line resistance.

• Be aware that V/f Control is comparatively limited when it comes to producing torque at low speeds.

• Consider switching to Open Loop Vector Control.

Cause Possible Solutions

The analog input gain and bias for the frequency reference input

are set to incorrect values.

• Check the gain and bias settings for the analog inputs that are used to set the frequency reference. Check parameters

H3-03 and H3-04 for input A1, check parameters H3-11 and H3-12 for input A2, and check parameters H3-07 and

H3-08 for input A3.

• Set these parameters to the appropriate values.

A frequency bias signal is being entered via analog input terminals

A1 to A3.

• If more than one of multi-function analog inputs A1 to A3 is set for frequency reference bias (H3-02, H3-10, or H3-06

is set to “0”), then the sum of all signals builds the frequency reference.

• Make sure that H3-02, H3-10, and H3-06 are set appropriately.

• Check the input level set for terminals A1 to A3 (U1-13 to U1-15).

PID control is enabled, and the drive is consequently adjusting the

output frequency to match the PID setpoint. The drive will only

accelerate to the maximum output frequency set in E1-04 while

PID control is active.

If PID control is not necessary for the application, disable it by setting b5-01 to “0”.

Cause Possible Solutions

Poor balance between motor phases. Check drive input power voltage to ensure that it provides stable power.

Hunting prevention function is disabled.

• Enable Hunting Prevention (n1-01 = 1).

• Increase the AFR gain (n2-01) or the AFR time constant (n2-02).

Cause Possible Solutions

L3-04 is set incorrectly.

• Check the Stall Prevention level during deceleration (L3-04).

• If a dynamic braking option has been installed, disable Stall Prevention during deceleration (L3-04 = 0).

The deceleration time is set too long. Set deceleration to more appropriate time (C1-02, C1-04, C1-06, C1-08).

Insufficient motor torque.

• Assuming parameter settings are normal and that no overvoltage occurs when there is insufficient torque, it is likely

that the demand on the motor has exceeded the motor capacity.

• Use a larger motor.

Reaching the torque limit.

• Check the settings for the torque limit (L7-01 through L7-04).

• If the torque limit is enabled, deceleration might take longer than expected because the drive cannot output more

torque than the limit setting. Ensure the torque limit is set to a high enough value.

• Increase the torque limit setting.

• If multi-function analog input terminal A1, A2, or A3 is set to torque limit (H3-02, H3-10, or H3-06 equals 10, 11, 12,

or 15), ensure that the analog input levels are set to the correct levels.

• Ensure H3-02, H3-10, and H3-06 are set to the right levels.

• Ensure the analog input is set to the correct value (U1-13 to U1-15).

Load exceeded the internal torque limit determined by the drive

rated current.

Switch to a larger capacity drive.

Cause Possible Solutions

The timing for the brake to close and release is not set properly. Refer to Notes on Controlling the Brake when Using the Hoist Application Preset on page 106.

Insufficient DC Injection Braking. Increase the amount of DC Injection Braking (b2-02).

Cause Possible Solutions

Loading...

Loading...