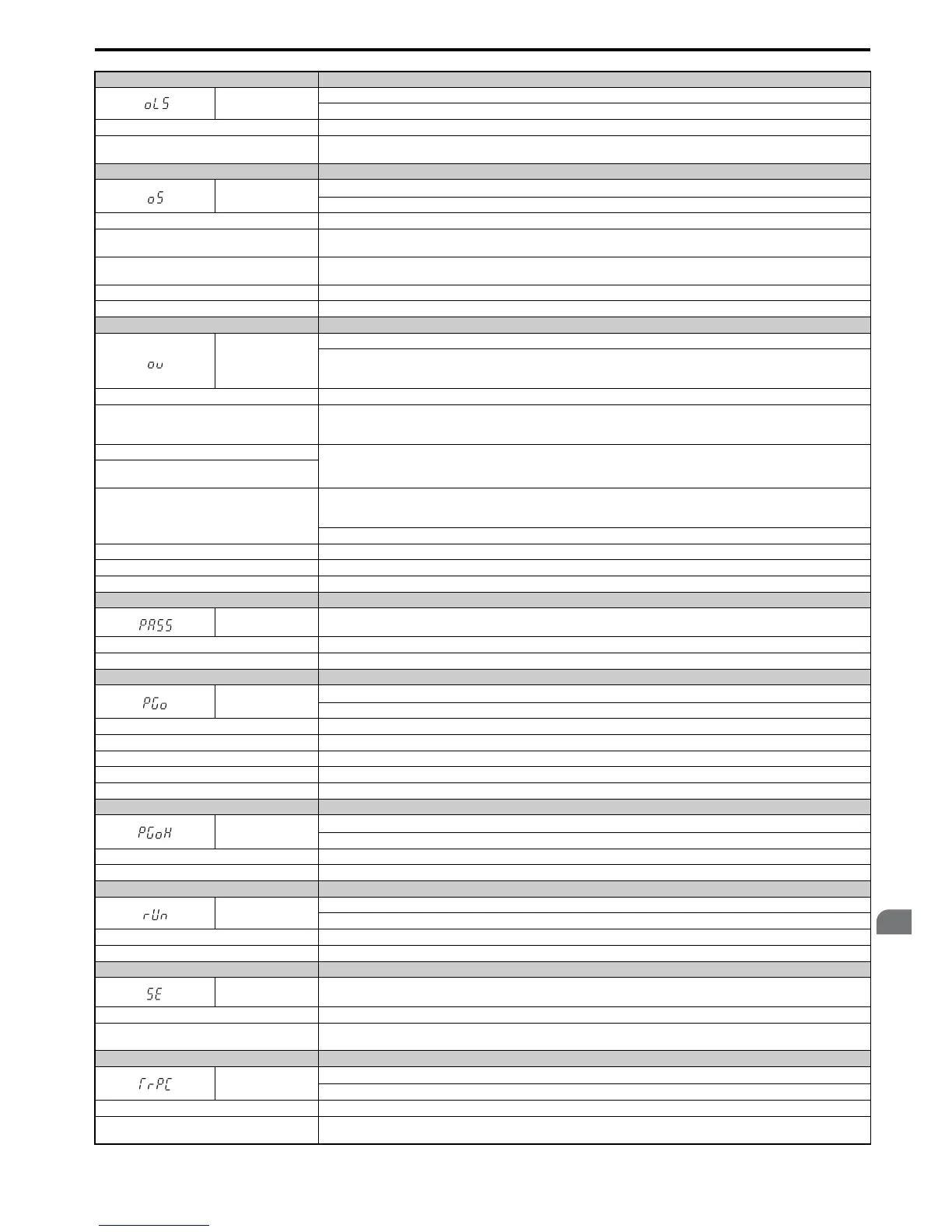

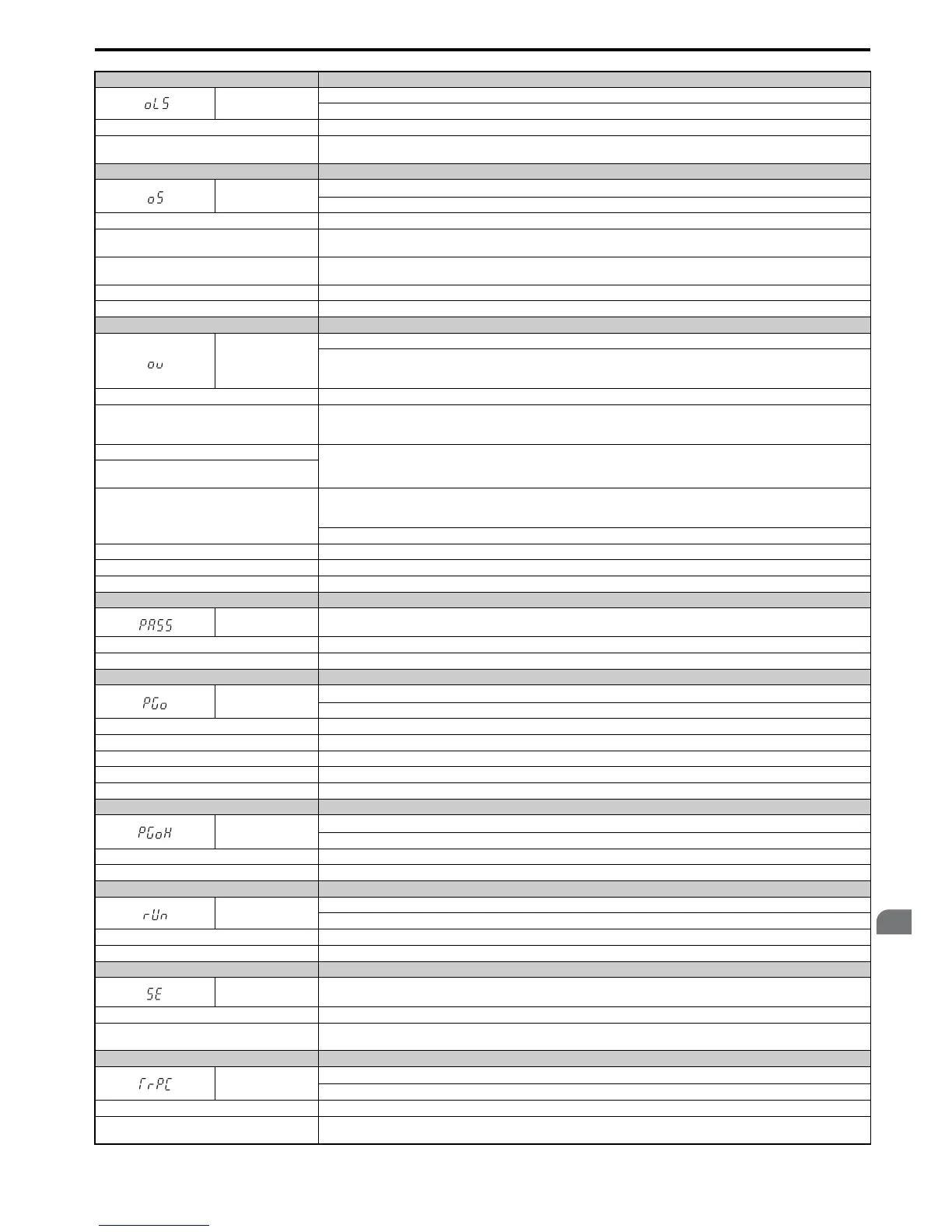

Digital Operator Display Minor Fault Name

oL5

Mechanical Weakening Detection 1

Overtorque occurred, matching the conditions specified in L6-08.

Cause Possible Solutions

Overtorque occurred, triggering the mechanical

weakening level set to L6-08.

• Check for the cause of mechanical weakening.

Digital Operator Display Minor Fault Name

oS

Overspeed (for Control Mode with PG)

The motor speed feedback exceeded the F1-08 setting.

Cause Possible Solutions

Overshoot is occurring.

• Increase the settings for C5-01 (Speed Control Proportional Gain 1) and reduce C5-02 (Speed Control Integral Time 1).

• If using a Closed Loop Vector mode enable Feed Forward Control and perform Inertia Auto-Tuning.

Incorrect speed feedback scaling if terminal RP is

used as speed feedback input in V/f control

• Set H6-02 to value of the speed feedback signal frequency when the motor runs at the maximum speed.

• Adjust the input signal using parameters H6-03 through H6-05.

Incorrect PG pulse number has been set • Check and correct parameter F1-01.

Inappropriate parameter settings. Check the setting for the overspeed detection level and the overspeed detection time (F1-08 and F1-09).

Digital Operator Display Minor Fault Name

ov

DC Bus Overvoltage

The DC bus voltage exceeded the trip point.

For 200 V class: approximately 410 V

For 400 V class: approximately 820 V

Cause Possible Solutions

Surge voltage present in the drive input power.

• Install a DC reactor or an AC reactor.

• Voltage surge can result from a thyristor convertor and a phase advancing capacitor operating on the same drive input power

system.

The motor is short-circuited.

• Check the motor power cable, relay terminals and motor terminal box for short circuits.

• Correct grounding shorts and turn the power back on.

Ground current has over-charged the main circuit

capacitors via the drive input power.

Noise interference causes the drive to operate

incorrectly.

• Review possible solutions for handling noise interference.

• Review section on handling noise interference and check control circuit lines, main circuit lines and ground wiring.

• If the magnetic contactor is identified as a source of noise, install a surge protector to the MC coil.

Set number of fault restarts (L5-01) to a value other than 0.

PG cable is disconnected. Reconnect the cable.

PG cable wiring is wrong. Correct the wiring.

Noise interference along PG encoder wiring. Separate PG wiring from the source of the noise (often output wiring from the drive).

Digital Operator Display Minor Fault Name

PASS

MEMOBUS/Modbus Comm. Test Mode Complete

Cause Possible Solutions

MEMOBUS/Modbus test has finished normally. This verifies that the test was successful.

Digital Operator Display Minor Fault Name

PGo

PG Disconnect (for Control Mode with PG)

Detected when no PG pulses are received for a time longer than setting in F1-14.

Cause Possible Solutions

PG cable is disconnected. Reconnect the cable.

PG cable wiring is wrong. Correct the wiring.

PG encoder does not have enough power. Make sure the correct power supply is properly connected to the PG encoder.

Brake is holding the PG. Ensure the brake releases properly

Digital Operator Display Minor Fault Name

PGoH

PG Hardware Fault (detected when using a PG-X3 option card)

PG cable has become disconnected.

Cause Possible Solutions

PG cable is disconnected. Reconnect the cable.

Digital Operator Display Minor Fault Name

rUn

Motor Switch during Run

A command to switch motors was entered during run.

Cause Possible Solutions

A motor switch command was entered during run. Change the operation pattern so that the motor switch command is entered while the drive is stopped.

Digital Operator Display Minor Fault Name

SE

MEMOBUS/Modbus Communication Test Mode Error

Note: This alarm will not trigger a multi-function output terminal that is set for alarm output (H2- = 10).

Cause Possible Solutions

A digital input set to 67H (MEMOBUS/Modbus

test) was closed while the drive was running.

Stop the drive and run the test again.

Digital Operator Display Minor Fault Name

TrPC

IGBT Maintenance Time (90%)

IGBTs have reached 90% of their expected performance life.

Cause Possible Solutions

IGBTs have reached 90% of their expected

performance life.

Replace the drive.

Loading...

Loading...