When connecting the drive to more than one motor for simultaneous operation, disable the electronic overload protection

(L1-01 = 0) and wire each motor with its own motor thermal overload relay.

Enable the motor overload protection (L1-01 = 1 to 5) when connecting the drive to a single motor, unless another motor

overload preventing device is installed. The drive electronic thermal overload function causes an oL1 fault, which shuts

off the output of the drive and prevents additional overheating of the motor. The motor temperature is continually

calculated as long as the drive is powered up.

■

L1-02 Motor Overload Protection Time

Setting Range: 0.1 to 5.0 min

Factory Default: 1.0 min

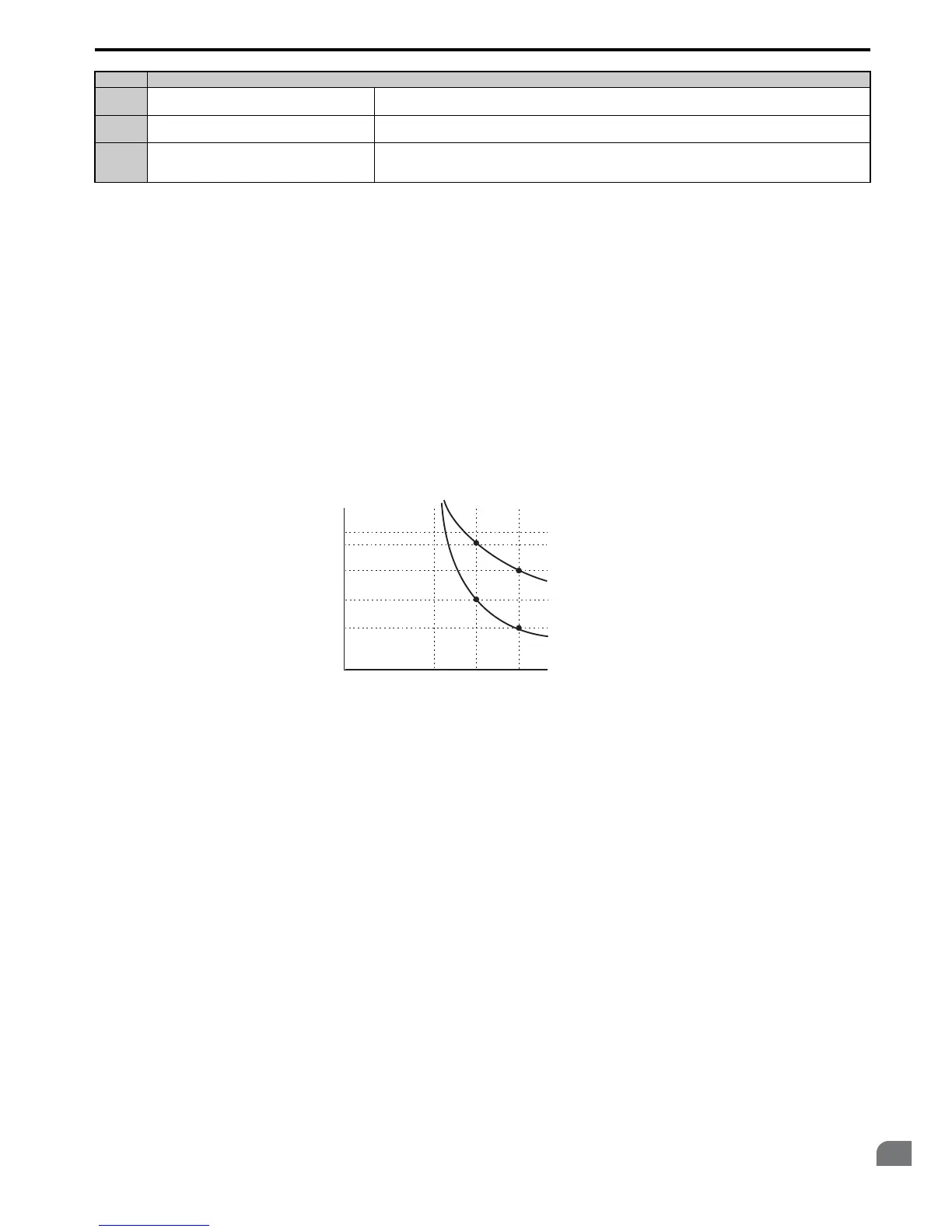

Parameter L1-02 determines how long the motor is allowed to operate before the oL1 fault occurs when the drive is

running at 60 Hz and at 150% of the full load amp rating (E2-01) of the motor. Adjusting the value of L1-02 can shift the

set of oL1 curves up the y axis of the diagram below, but will not change the shape of the curves.

Figure D.7

Figure D.7 Motor Overload Protection Time

4 Permanent Magnet motor with variable torque

Selects protection characteristics for a variable torque PM motor. The motor overload detection level (oL1) is

automatically reduces when running below the motor rated speed.

5 Permanent Magnet motor with constant torque

Selects protection characteristics for a constant torque PM motor. The motor overload detection level (oL1) is constant

over the whole speed range.

6 Standard fan cooled motor (50 Hz)

Selects protection characteristics for a standard self cooled motor with limited cooling capabilities when running below

the rated speed. The motor overload detection level (oL1) is automatically reduces when running below the motor rated

speed.

Setting Description

10

7

3

1

0.4

0.1

0 100 200150

Cold Start

Hot Start

Motor Current (%)

(E2-01=100 %)

Time (min)

Loading...

Loading...