L: Printhead Maintenance

Printhead Terminology

P1061317-002 Zebra ZXP Series 3 Card Printer Service Manual 349

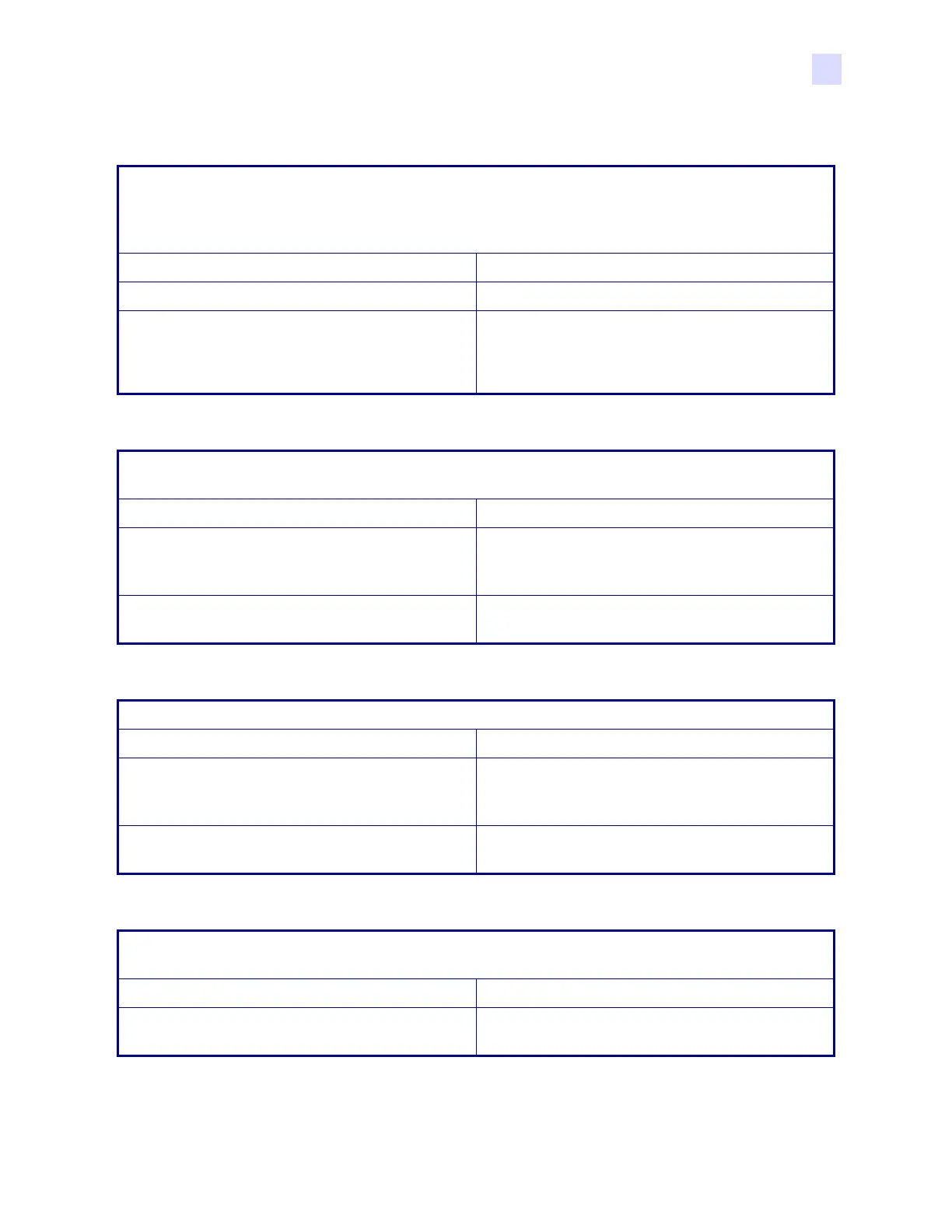

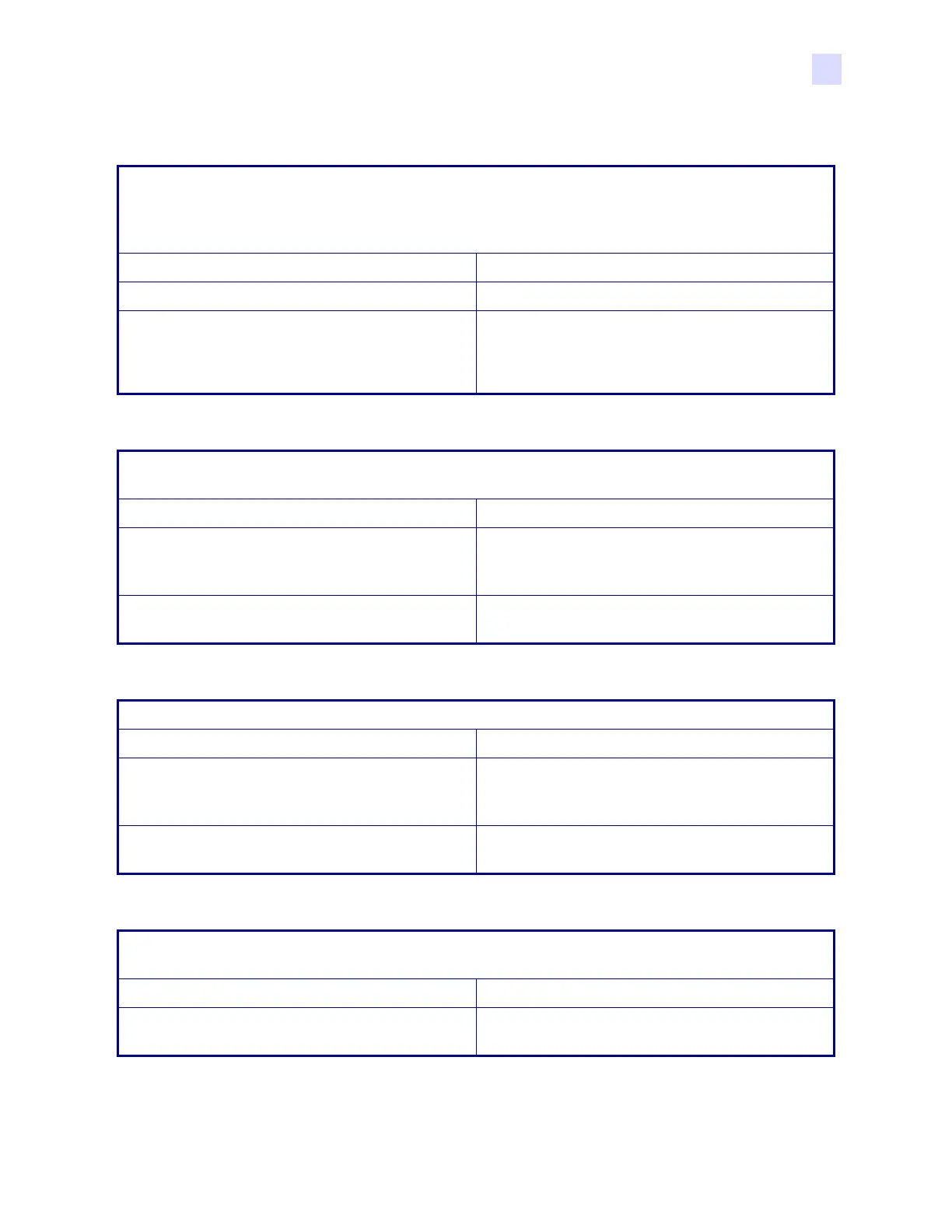

Table 2 • Contamination

Media can contain or be introduced to abrasive contaminants that pass through the printhead and scrape or

cut through the protective coating on the printhead. Once the protective element coating is damaged,

printhead element failure occurs. If premature or random printhead failure occurs as a result of a scratched

printhead element, the media or environment may be introducing contamination.

Contributing Factor Recommendation

Contaminated Media Consult with your media supplier.

Environment Protect the media from exposure to contamination.

If printer location is problematic, consider using a

protective enclosure.

Table 3 • Corrosion

Substances in contact with the printhead elements can become corrosive and can generate caustic agents

when heated, causing corrosion of the protective coating and printhead failure.

Contributing Factor Recommendation

Physically touching the printhead element surface

with the human skin can cause contamination

detrimental to the life of the printhead.

Clean any surface with an approved cleaning solution

before operating the printer. Consult your printer’s

User Manual for recommended cleaning procedures.

Improper cleaning or use of unapproved solutions on

the printhead.

Use only approved cleaning items for printhead

cleaning; see See “Cleaning Supplies” on page 354.

Table 4 • Electrostatic Discharge (ESD)

Electrostatic discharge can damage the internal electronic circuitry.

Contributing Factor Recommendation

Improper handling of the printhead assembly Refer to your printer’s user guide for more

information about how to prevent ESD when

handling the printhead.

Static buildup from media/ribbon Ensure that any static brushes (if applicable) and

printhead mechanism wiring are properly secured.

Table 5 • Residue

Buildup of ribbon coating or direct thermal media coatings on the printhead elements can interfere with heat

transfer, causing the heater elements to overheat to the point of failure

Contributing Factor Recommendation

Improper maintenance Follow recommended cleaning intervals using the

proper cleaning accessories.

Loading...

Loading...