Troubleshooting

6850

6850

Released: April 2004 6850 Series Gas Chromatograph Service Procedures 275

Liner selection for split application not only

affects inlet back pressure at low operating

pressures, but also split precision, linearity

and boiling point discrimination. Any liner

that has a restrictive design at the bottom,

like a check valve, gooseneck or spiral will

adversely affect chromatographic perfor-

mance.

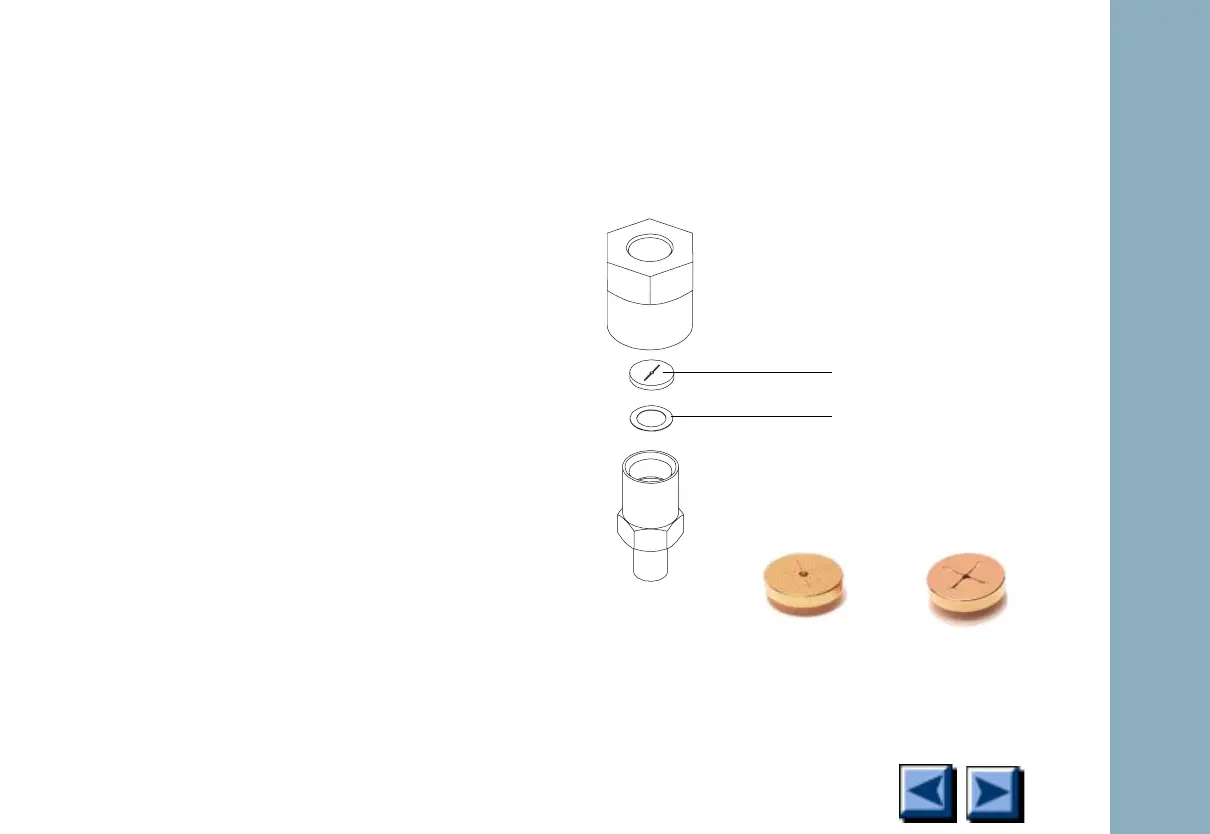

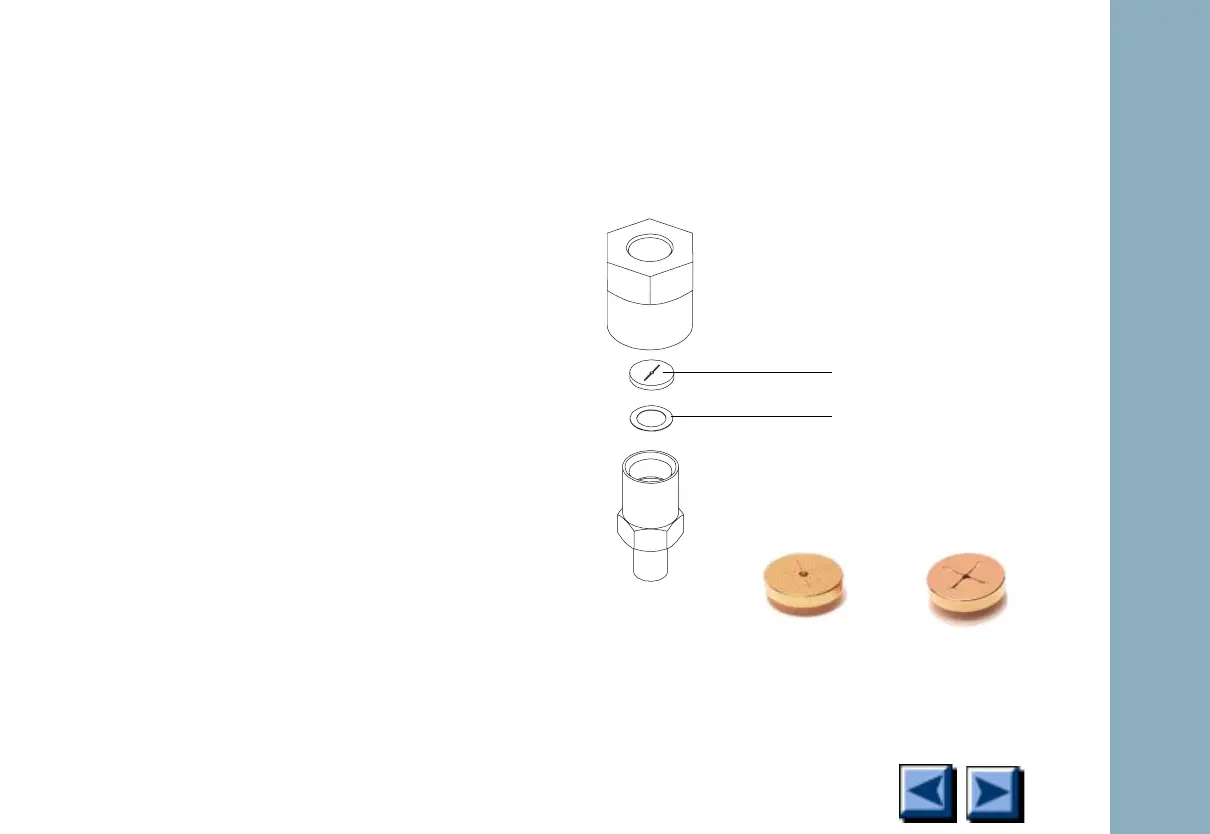

2. Inspect and clean the split exit fitting of the

injection port body and clean or replace the

1/8-inch copper tube between the split exit

fitting and the split vent trap.

3. Replace the cartridge filter in the split vent

trap assembly. If the trap design does not

incorporate the replaceable cartridge filter,

install upgrade kit part number

G1544-60610.

4. If not using a recommended Agilent glass

split injection port liner, there is an optional

gold seal that accommodates higher split

vent flow rates without developing

unwanted inlet back-pressure.

Gold seal

Washer

Standard

gold seal

18740-20885

High split flow

gold seal

5182-9652

Loading...

Loading...