Troubleshooting

6850

6850

Released: April 2004 6850 Series Gas Chromatograph Service Procedures 300

There will be no carrier flow, because the

column is disconnected and the detector

fitting plugged. Measure the H

2

, air and

makeup gas flows independently by turning

them on one at a time from the GC front

panel or Control Module. They should be

within ±10% of the setpoint. If the flows

are significantly off, the jet could be partially

plugged, there could be a leak anywhere in

the FID pneumatic system, or the detector

EPC module could be defective. Remember

that flow measurement from a soap film

bubble meter are affected by ambient pres-

sure. flow modules are calibrated at Stan-

dard Temperature and Pressure. For accurate

readings, use a true mass flow measurement

device (such as the Agilent Flow Tracker

1000). Resolve any flow control problems

and retest the FID noise.

6. Perform FID maintenance per the GC opera-

tors manual.

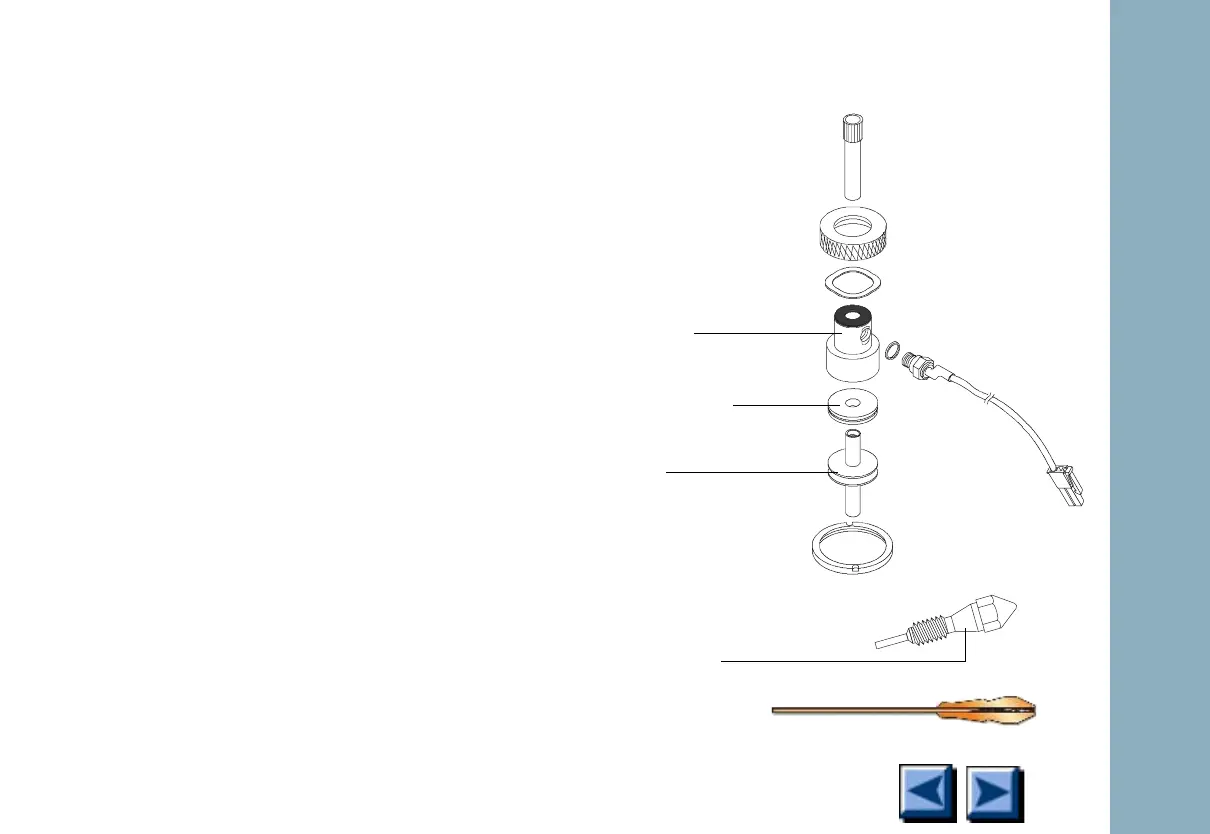

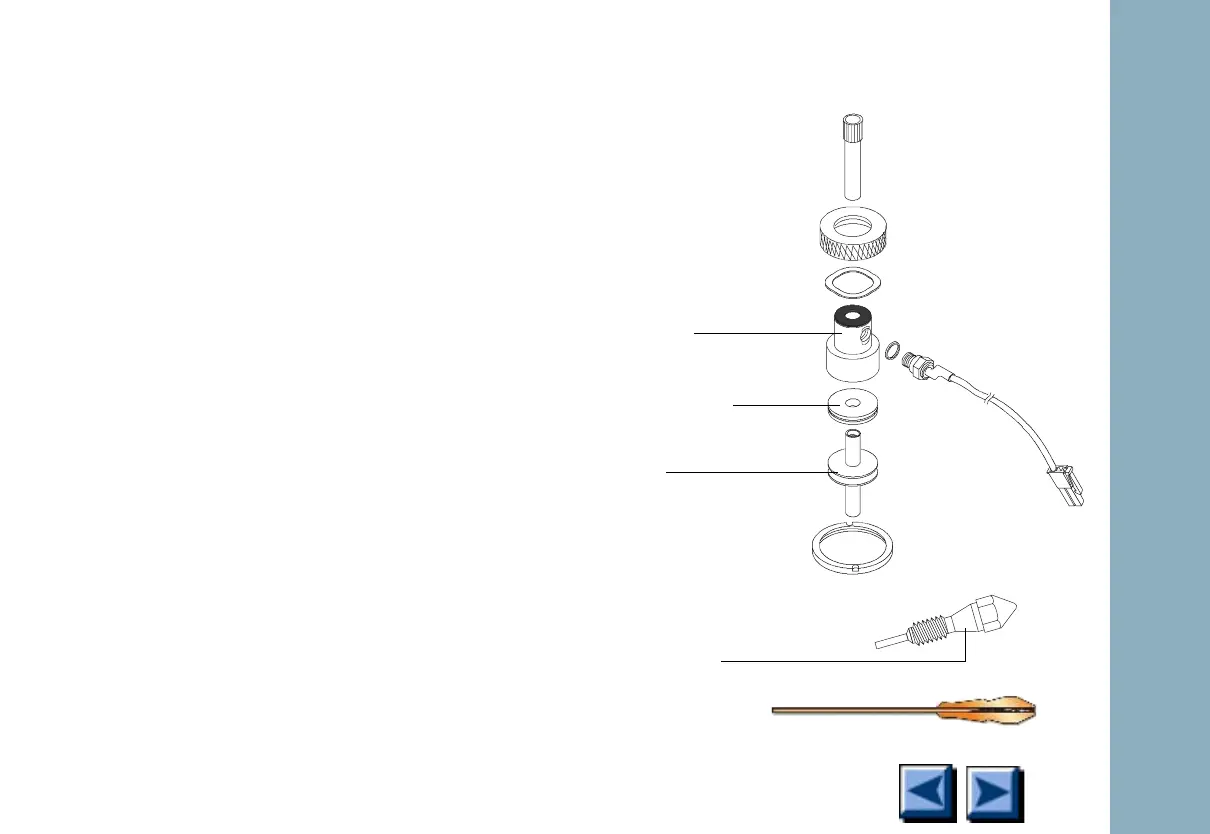

Collector

Teflon insulators

Brass castle

assembly

Sealing surface

Partially plugged jet

Loading...

Loading...