186 MAX Operation & Service Manual186 Section7:Troubleshooting MAX Operation & Service Manual

MECHANICAL FAILURES

Tables 7-16 through 7-21 provide a list of possible mechanical failures and the steps to correct them. If

you need assistance, please contact your Brunswick Distributor or Brunswick Technical Support (BTS)

in the United States at 1-800-YES-BOWL, or internationally at 231-725-4966. For non emergency

support, e-mail techsupport@brunswickbowling.com.

List Of Mechanical Failure Categories

Duster Cloth Assembly - Table 7-16

Cleaning System - Table 7-17

Conditioning Appearance & Application - Table 7-18

Traction Drive System - Table 7-19

Electrical System - Table 7-20

Tablet - Table 7-21

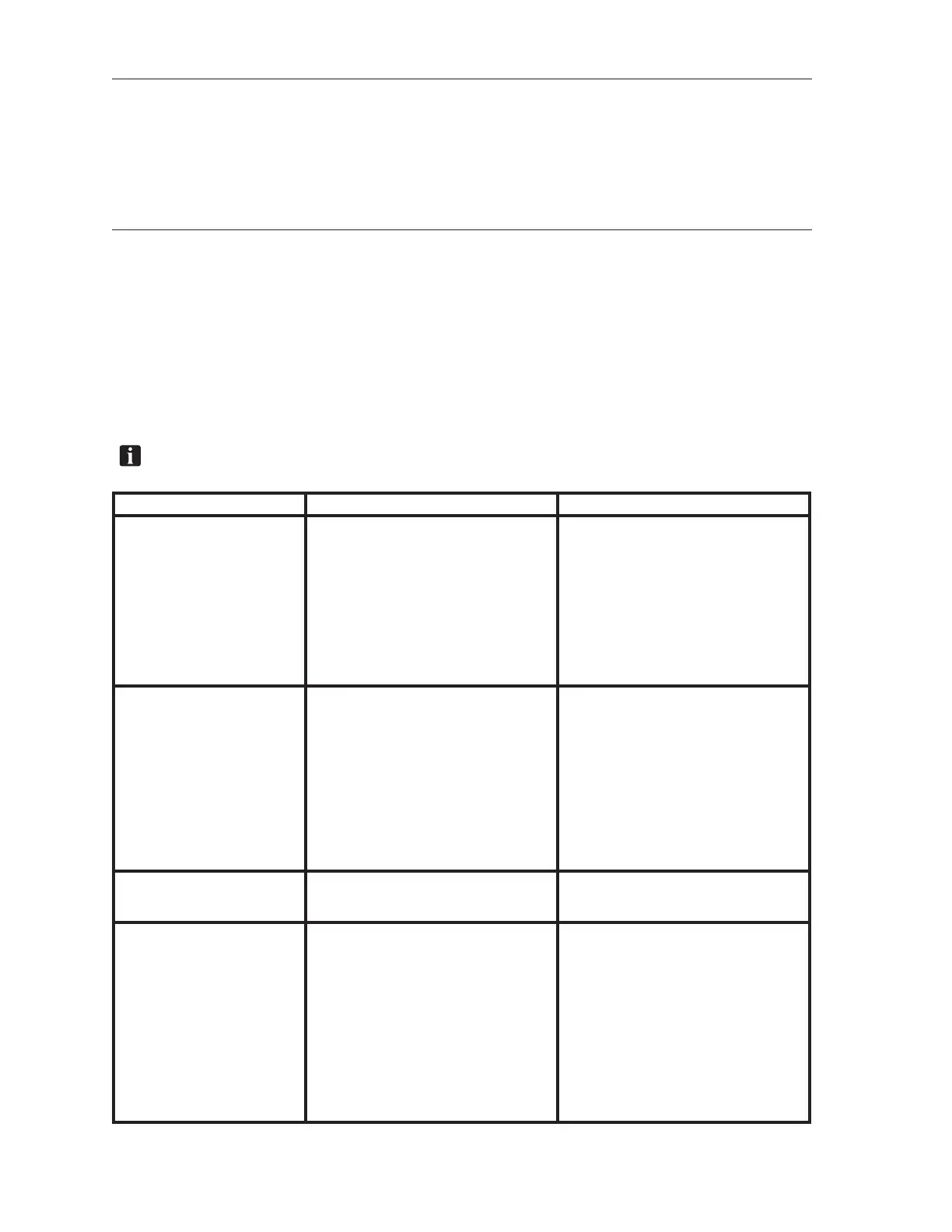

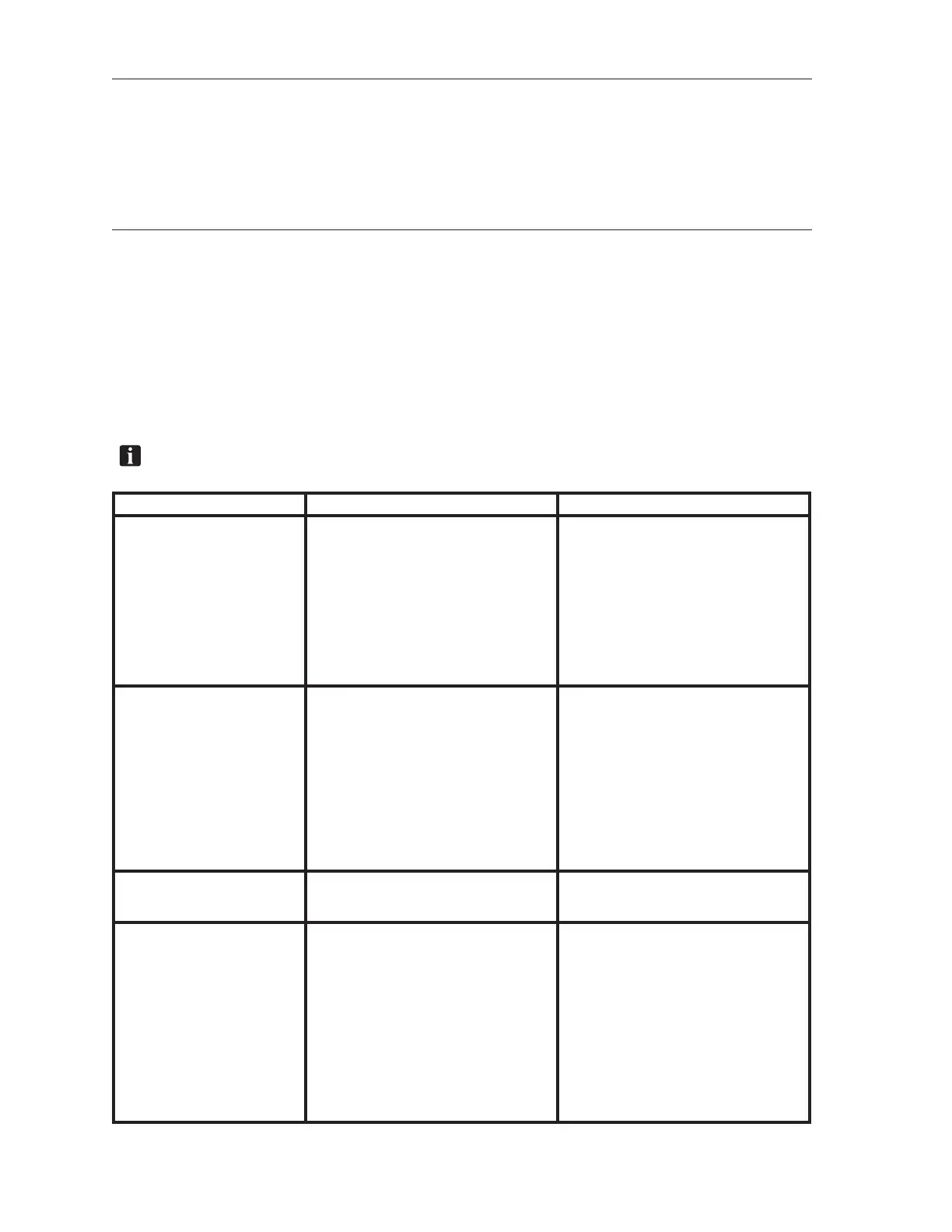

Duster Cloth Assembly - Table 7-16

NOTE::VerifyerrorsourcethroughTabletdiagnostics.

Problem Cause Solution

Machine leaving lines of dust on

the lane.

1. Duster cloth is too wet

2. Duster clutch is too tight, cloth is not

advancing

1. Option 1: Verify correct cleaner pres-

sure.

Option 2: Adjust spray nozzles away from

duster cloth.

2. Loosen clutch adjustment

See Adjusting the duster cloth for more

information

Duster cloth is not dusting entire

lane.

1. Duster contact roller is not lowering

completely

2. Duster contact roller has at spots or

depressions

1. Option 1: Check for binding in roller

movement.

Option 2: Check for uneven winding of

cloth.

2. Option 1: Replace contact roller cushion

tube.

Option 2: Check lane for topography

problems.

Duster assembly chatters on

back of lane

1. Contact roller cushion has a at spot 1. Replace contact roller cushion tube

Duster cloth is dragging on lane

during return run

1. Clutch is adjusted too loose

2. Loose hub on duster cloth motor shaft

3. Hub on take up core is loose and slip-

ping

4. Duster cloth motor failure

1. Tighten clutch adjustment per manual

See Adjusting the duster cloth for more

information

2. Tighten set screw in hub

3. Repair or replace hub on cardboard take

up core

4. Verify motor function using Tablet diag-

nostics and replace if necessary

Loading...

Loading...