MAX Operation & Service Manual 193MAX Operation & Service Manual Section8:LaneMaintenanceandPatternDesignTheory193

Section 8: Lane Maintenance and

Pattern Design Theory

LANE MAINTENANCE

Identifying Your Maintenance Needs

It is important to understand and identify the type of maintenance that is required in your center.

Every bowling center is a different environment, in a different geographic area. These are just some

factors that you should be aware of when creating your maintenance plan, which included your cleaner,

conditioner and cloth (3C’s). Dirt is your worst enemy! Controlling dirt in your center is key to

protecting the equipment and reducing maintenance costs associated with a lack of maintenance.

1. Recognize your geographic region.

The region of the world in which you live can dictate the type and frequency of general

maintenance you need to perform and how you need to store your equipment and supplies.

Eliminating issues with dirt and varying temperatures as the seasons change. Store your Lane

machine, conditioners, and cleaners in a room that has temperature control. Conditioners can

become thicker and cleaners can crystallize when they become cold. This can increase the

preparation time to set up the machine and possibly affect the characteristics of the products.

The amount of dirt your center produces can affect lane pattern as well as damage the lane

surface, gutters and eventually affect your pin setting or spotting equipment.

2. Identify your bowling environment.

Stopping dirt begins at the main entrance of your center. Having entry way rugs or mats are

your rst line of defense in reducing the migration of dirt throughout the center. Keeping the

oors clean and free of dirt and dust. Regulating the temperature helps eliminate the stresses

that affect the topography of the lane surface as temperatures change. This will also help

minimize the effect of humidity. These variables all affect the oil pattern and ball reaction

consistency.

3. Inspect your lanes and approaches

It is good practice to inspect your lanes and approaches on a regular basis. Inspections of panel

seams for a proper seal and for lane plugs that are raised or missing help prevent more costly

damage in the future.

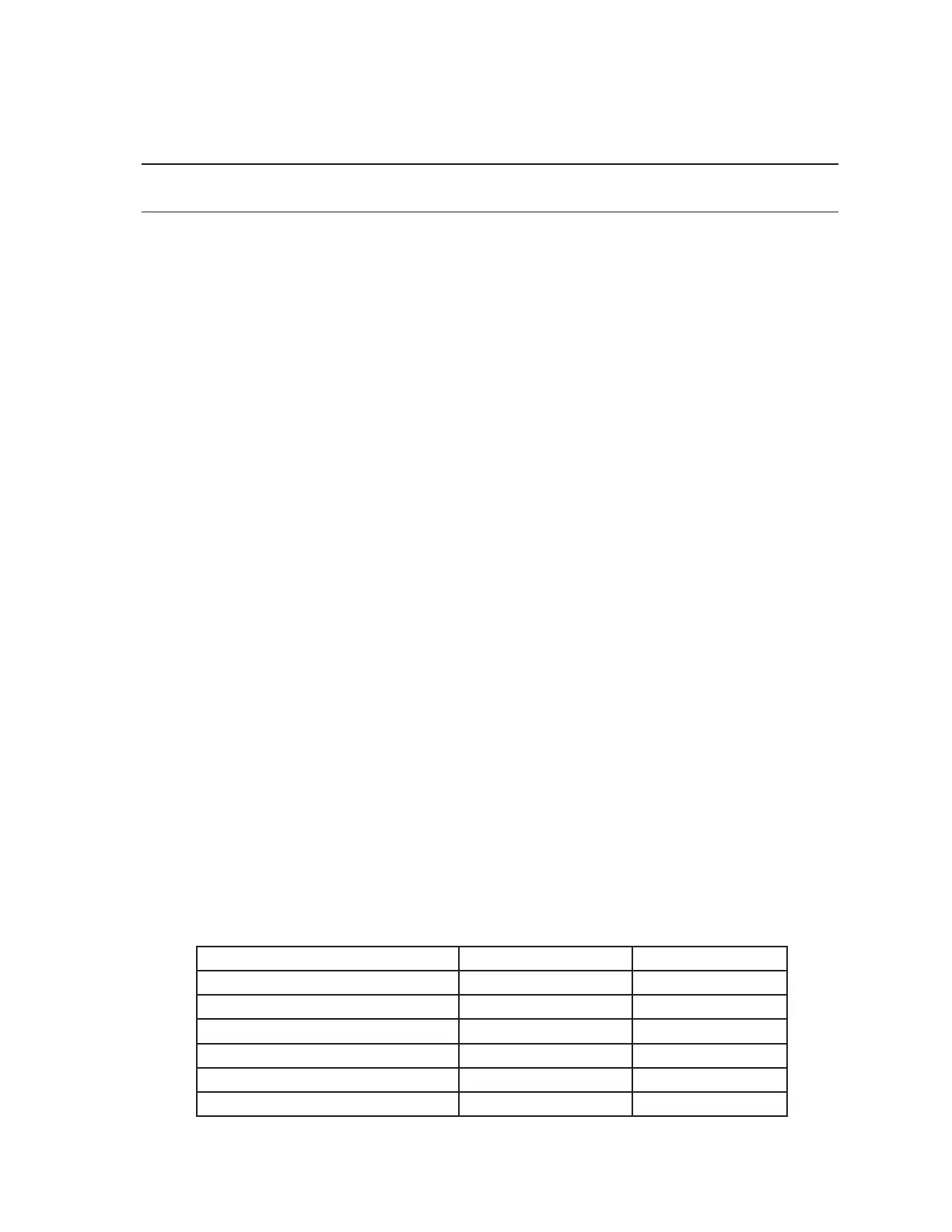

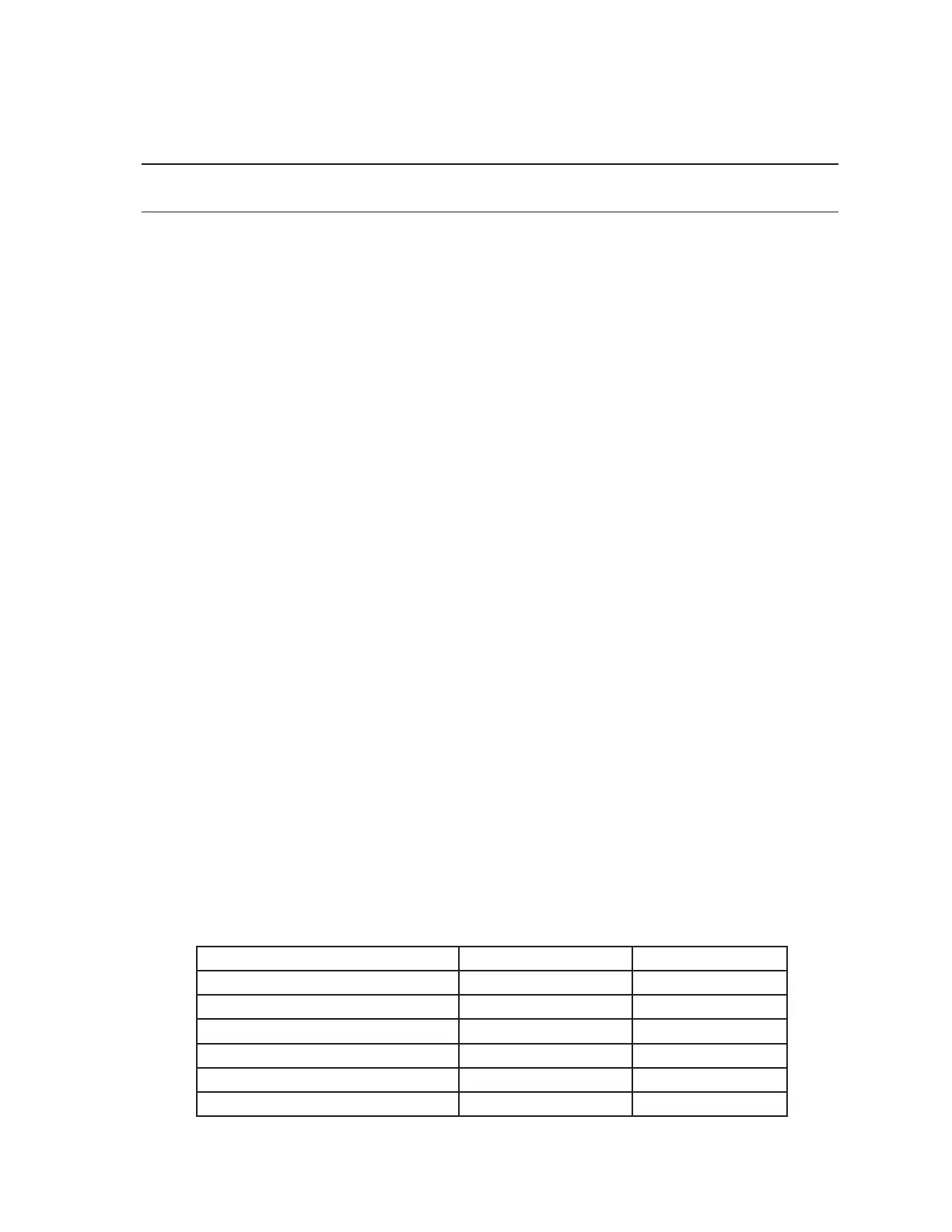

4. Create your maintenance plan.

Once you know how dirty your center is, a plan can be made based on that information.

Below is a list of maintenance procedures and our recommendation of the frequency of the

maintenance.

Maintenance Minimum Maximum

Dusting gutters Twice per week Daily

Dusting approaches Daily Three times per day

Spot cleaning approaches Daily Three times per day

Deep cleaning approaches Monthly Weekly

Washing gutters and at gutters Yearly Monthly

Inspect panel seams and lane plugs Yearly Monthly

Loading...

Loading...