SECTION 5 - OPENER SERVICE

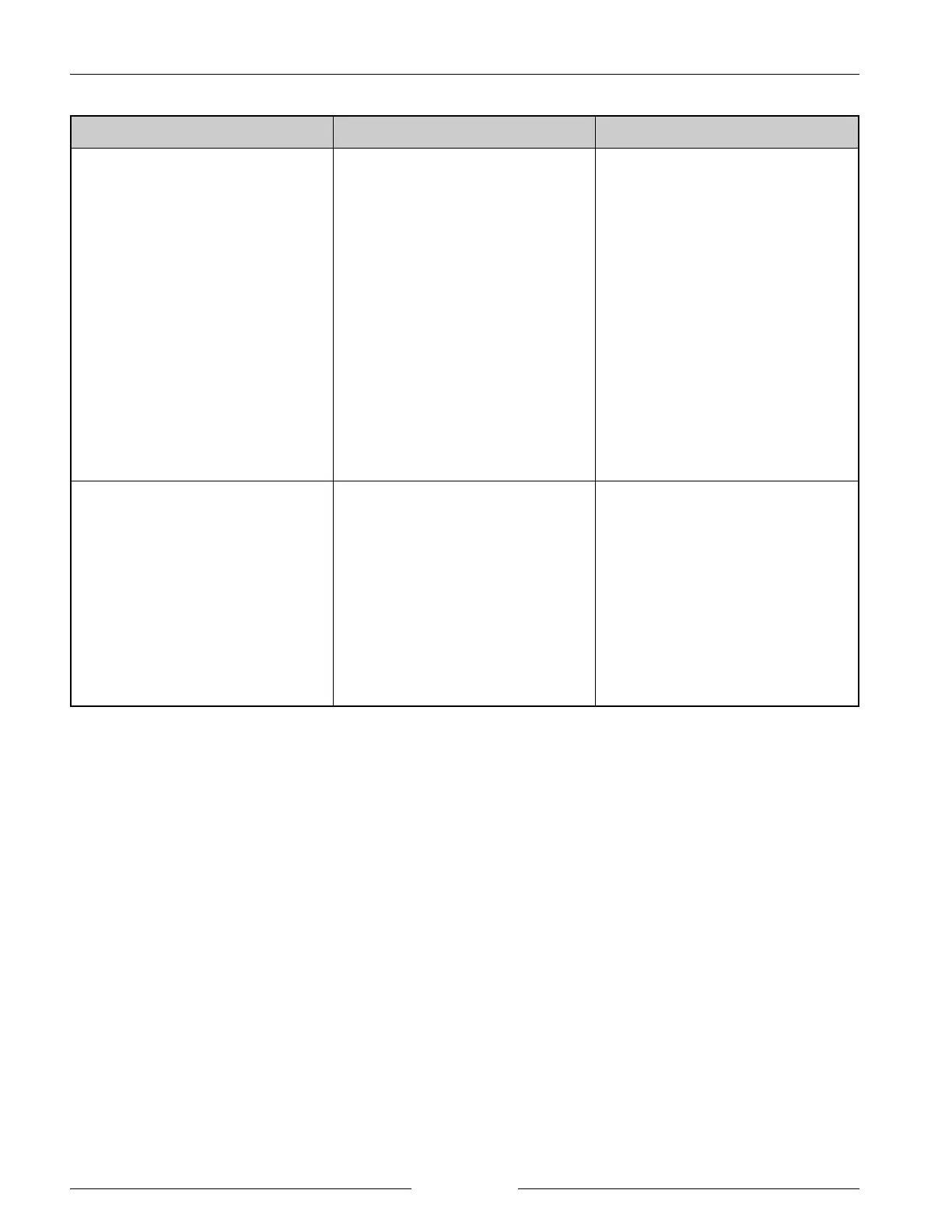

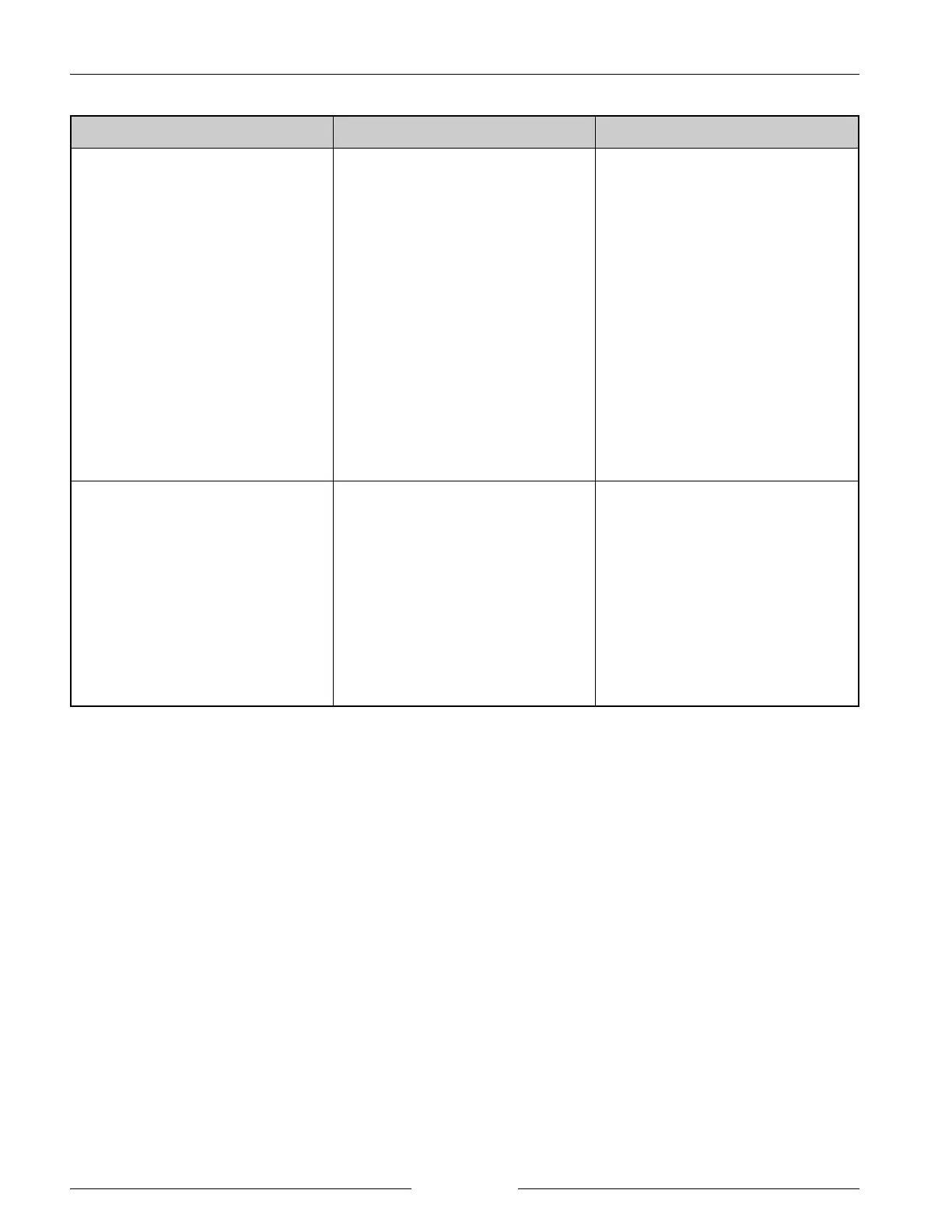

PROBLEM POSSIBLE CAUSES POSSIBLE SOLUTIONS

page 5-4

Poor seed placement 1. Worn scrapers.

2. Inadequate down pressure .

3. Improper packing force.

4. Variable residue.

5. Broken / worn seed retaining

tab.

6. Improper air flow velocity.

7. Worn disk.

1. Replace scrapers .

2. Increase opener down pressure

adjustment.

3. Ensure adequate and proper

packing force.

4. Harrow residue to ensure even

distribution.

5. Replace tab.

6. Adjust air system fan rpm.

7. Replace disk.

Plugging of gauge wheels 1. Gap too large between disk and

gauge wheel.

2. Interference between disk and

gauge wheel.

3. Wet field conditions.

1. Remove spacers between gauge

wheel and gauge arm to obtain a

gap of lightly touching to 3 mm

(1/8”).

2. Add spacers between gauge

wheel and gauge arm to obtain a

gap of lightly touching to 3 mm

(1/8”).

3. Wait for soil conditions to dry.

Loading...

Loading...