SECTION 3 - HYDRAULIC SYSTEM SERVICE

page 3-3

DANGER!

CAUTION!

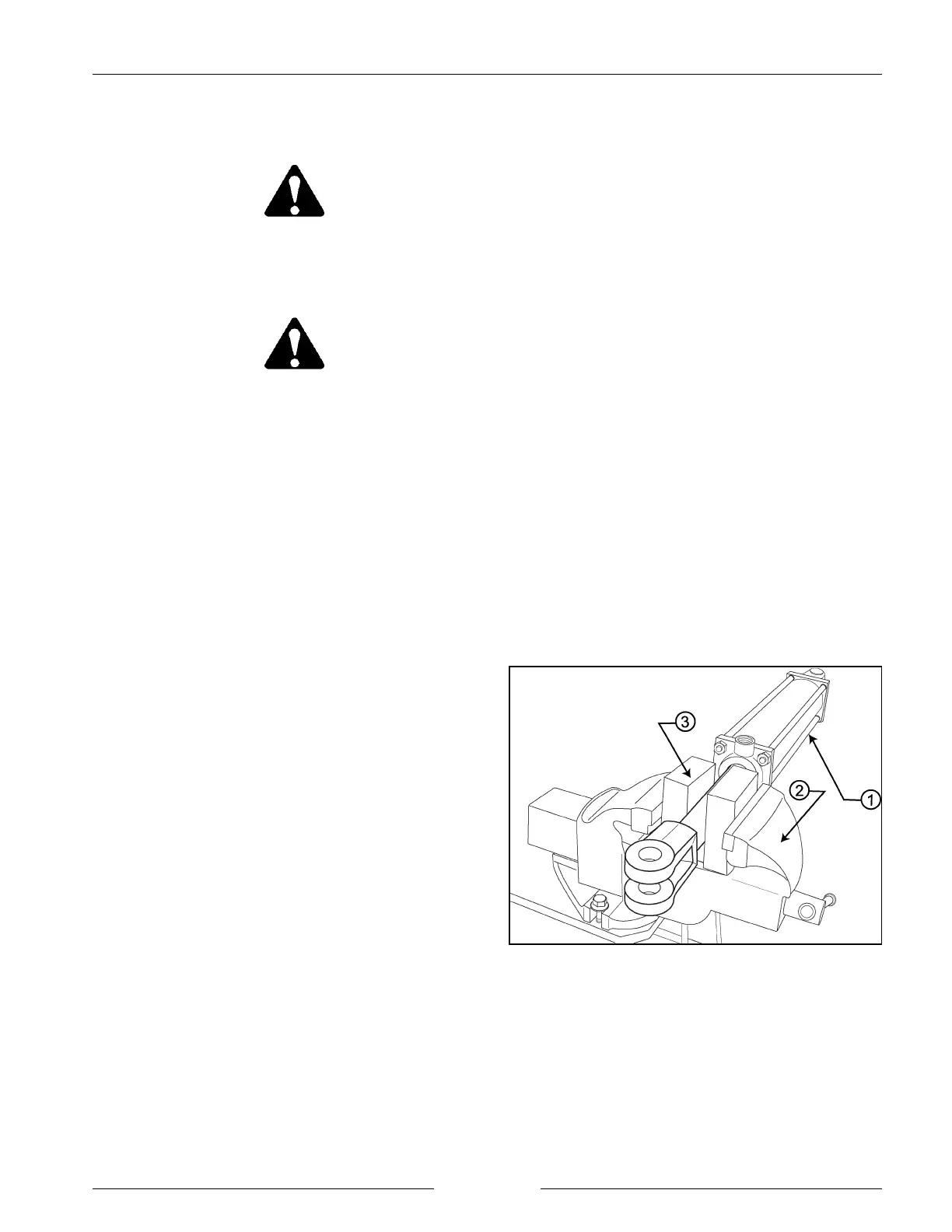

Cylinder in Vise

202035M1

HYDRAULICS

After hydraulic repair or maintenance, bleed the

air from the hydraulic system. Air in the system

could cause a loss in pressure. This loss in

pressure could cause the wings to fall

unexpectedly causing death or serious injury.

Stand clear of the machine when the hydraulic

cylinders are being extended and retracted.

ESCAPING HYDRAULIC FLUID IS A SERIOUS

HAZARD. Escaping hydraulic fluid that is under

pressure can penetrate the skin causing serious

injury. Relieve pressure before disconnecting the

hydraulic lines. Do not over-tighten swivel

connections. Check/tighten all connections

BEFORE activating hydraulics.

IMPORTANT: Use a thread sealant on male to female pipe thread connections only. Do not use a thread

sealant on O.R.B. or swivel connections.

HYDRAULIC CYLINDER SEAL REPLACEMENT

REMOVE CYLINDER FROM DRILL

IMPORTANT: The procedure shown is for the wing lift cylinders on the drill. Subbar cylinder repair is similar.

Refer to the subbar cylinder diagrams for location of seals etc. Note that the subbar cylinders

do not have tie rods.

1. Make sure the implement is fully lowered into field

position and the openers are resting on the ground.

Stop the tractor engine and move the tractor hydraulic

remote lever back and forth several times to relieve

pressure in the system.

2. Clean the areas on and around the cylinder, near the

fittings that attach the lines or hoses to the cylinder.

3. Remove all fittings and drain the oil from the cylinder.

Loosen the lines slowly to allow the release of any

residual pressure. Plug the hoses and fittings.

4. Remove the cylinder from the drill.

5. Remove all fittings and drain the oil from the cylinder.

6. Block the cylinder (1) in a vise (2) using wooden

blocks (3) or other material to protect the cylinder rod

from damage.

Loading...

Loading...