SECTION 6 - AIR SYSTEM SERVICE

page 6-9

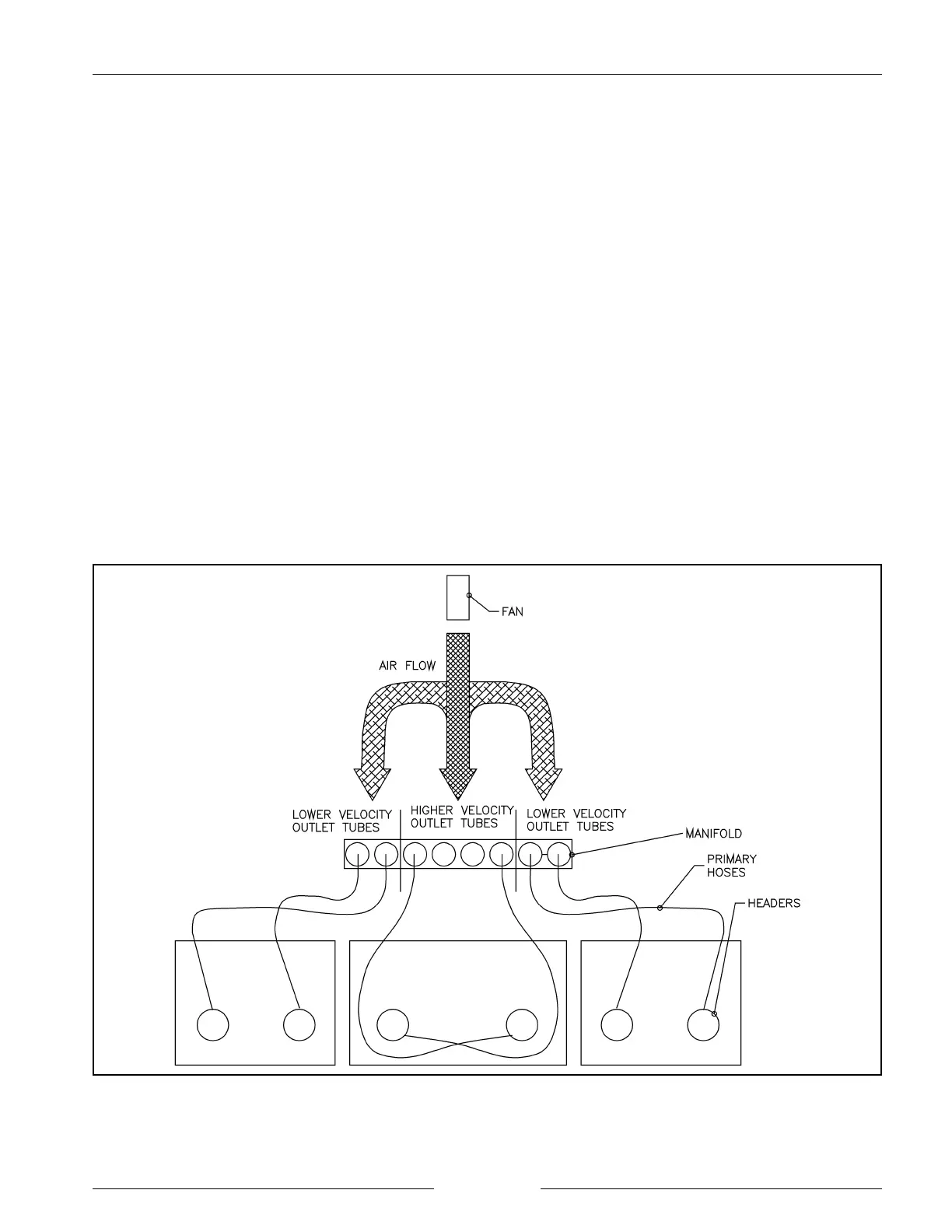

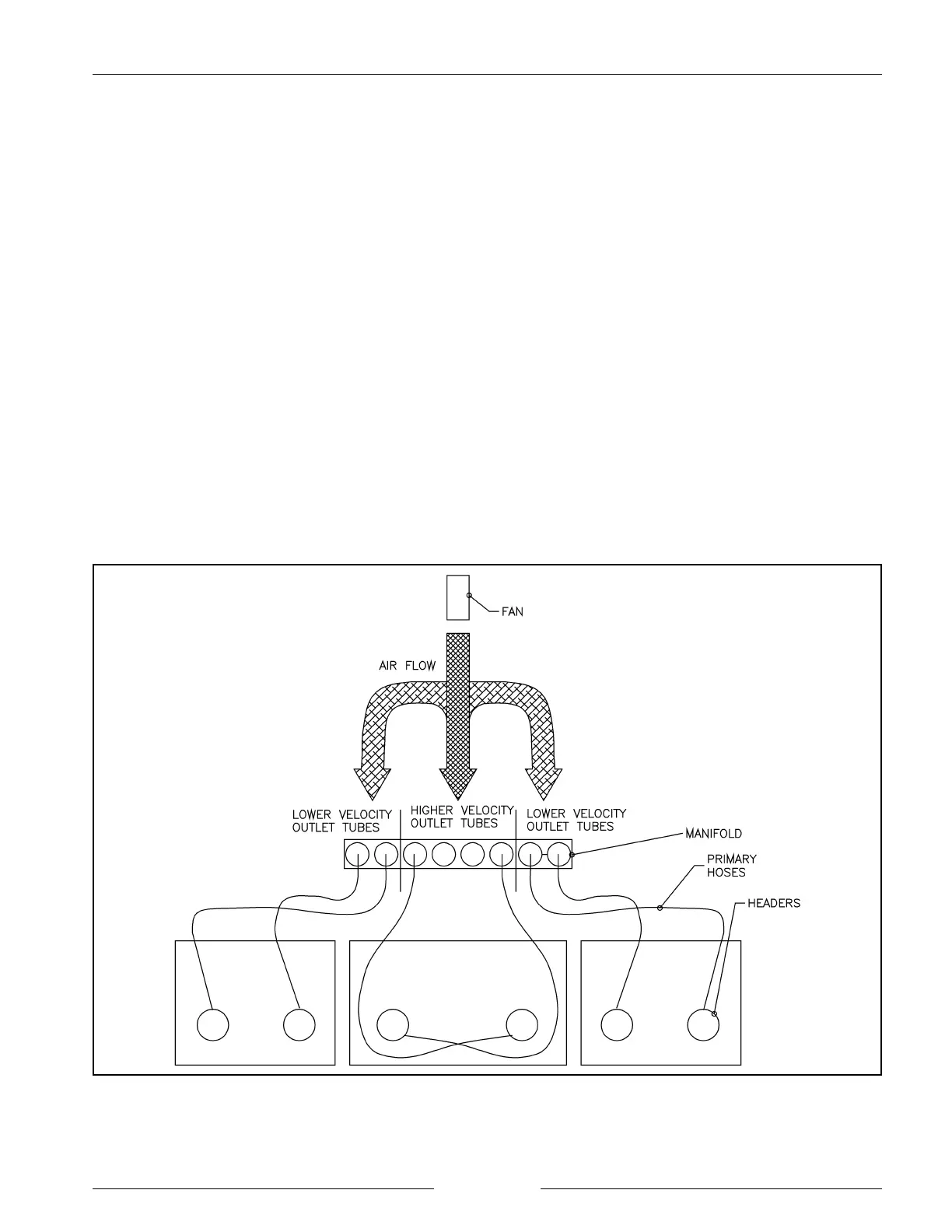

Air Flow to the Implement

202068C

THEORY OF OPERATION - AIR SYSTEM

NOTE: Refer to your air cart service manual for more

information on the air delivery system from

the air cart to the tillage equipment.

Maintaining similar lengths of hose on all 2 1/2" inch

primary lines is extremely important. The pressure across

all the primary lines at the meter box must be as close as

possible to reduce the chance of both cross migration of

product between the primary lines, and the suction of

extra product past the meter roller.

Since the pressure at the meter box is the sum of all the

pressure drops through the primary lines and the pressure

drop is directly dependant on length of the hoses, the

hoses must be kept as close to each other in length as

possible.

An acceptable length difference would be about four feet.

The hoses with more bends can also cause pressure drops

and therefore should be shorter. The shorter hoses can be

crossed over at the manifold and hitch area to allow for

the extra equalizing of length.

It is important that no hose ever be looped, causing the

product to do a 360

/ change in direction. The air flow

through the product delivery tubes into the manifolds is

not uniform. The inner tubes have higher air velocity

than the outer tubes. At low fan speeds this may not be

apparent; it is more noticeable at high fan speeds.

BALANCING THE AIR FLOW

Balance the air system by either increasing the length of

primary hoses or gently looping them. Length of the

hoses should be similar, with the longer hoses going to

the outside headers. When installing an air package on a

seeding tool it is critical to make the left side hose layout

a mirror image of the right side. Avoid sharp bends,

corners, and kinks when routing hoses as hose life can be

reduced and product flow will be affected. To ensure a

balanced air flow, you can test product delivery. Refer to

‘Methods of Determining Adequate Carrying Velocities’.

Loading...

Loading...