SECTION 5 - OPENER SERVICE

page 5-7

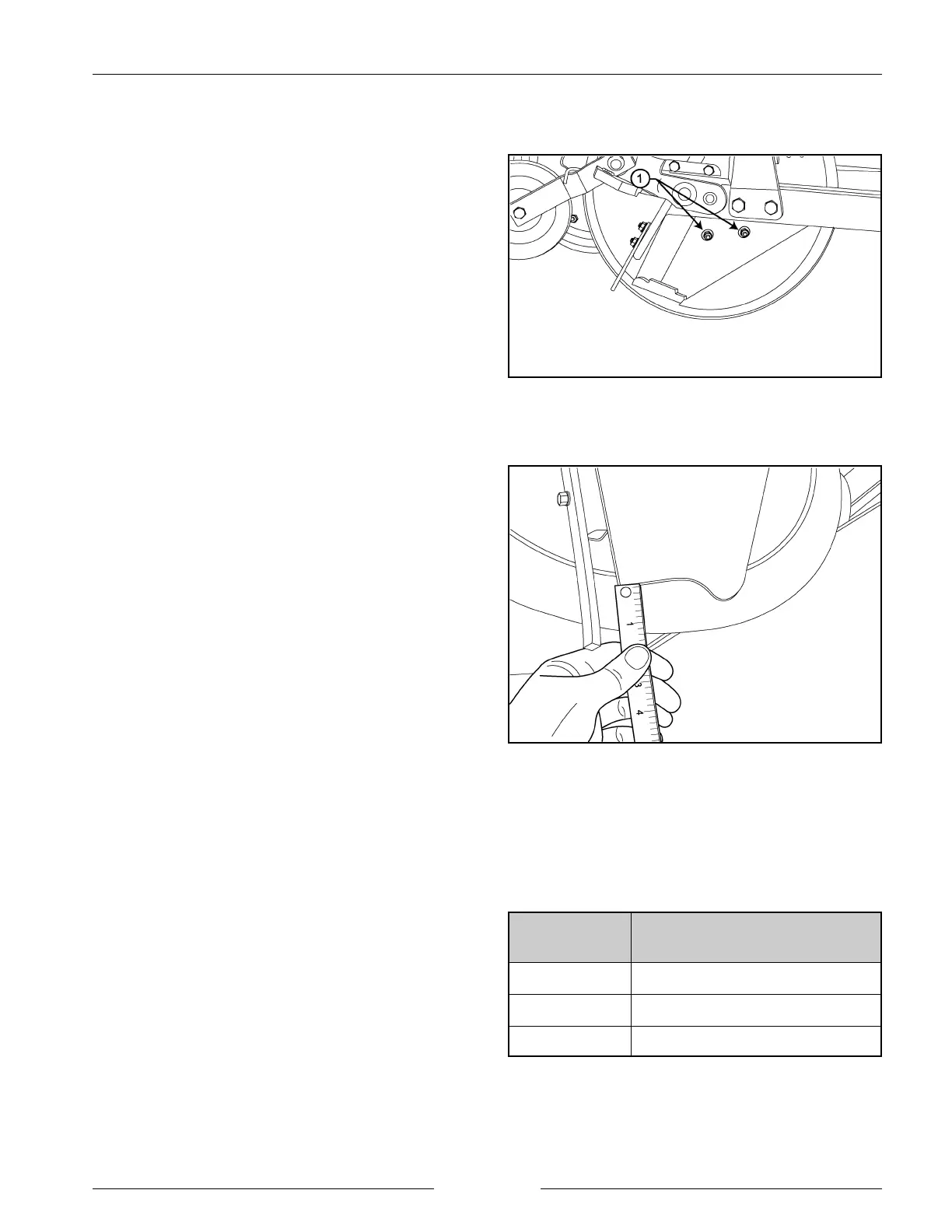

Tighten Scraper Nuts

202179M1

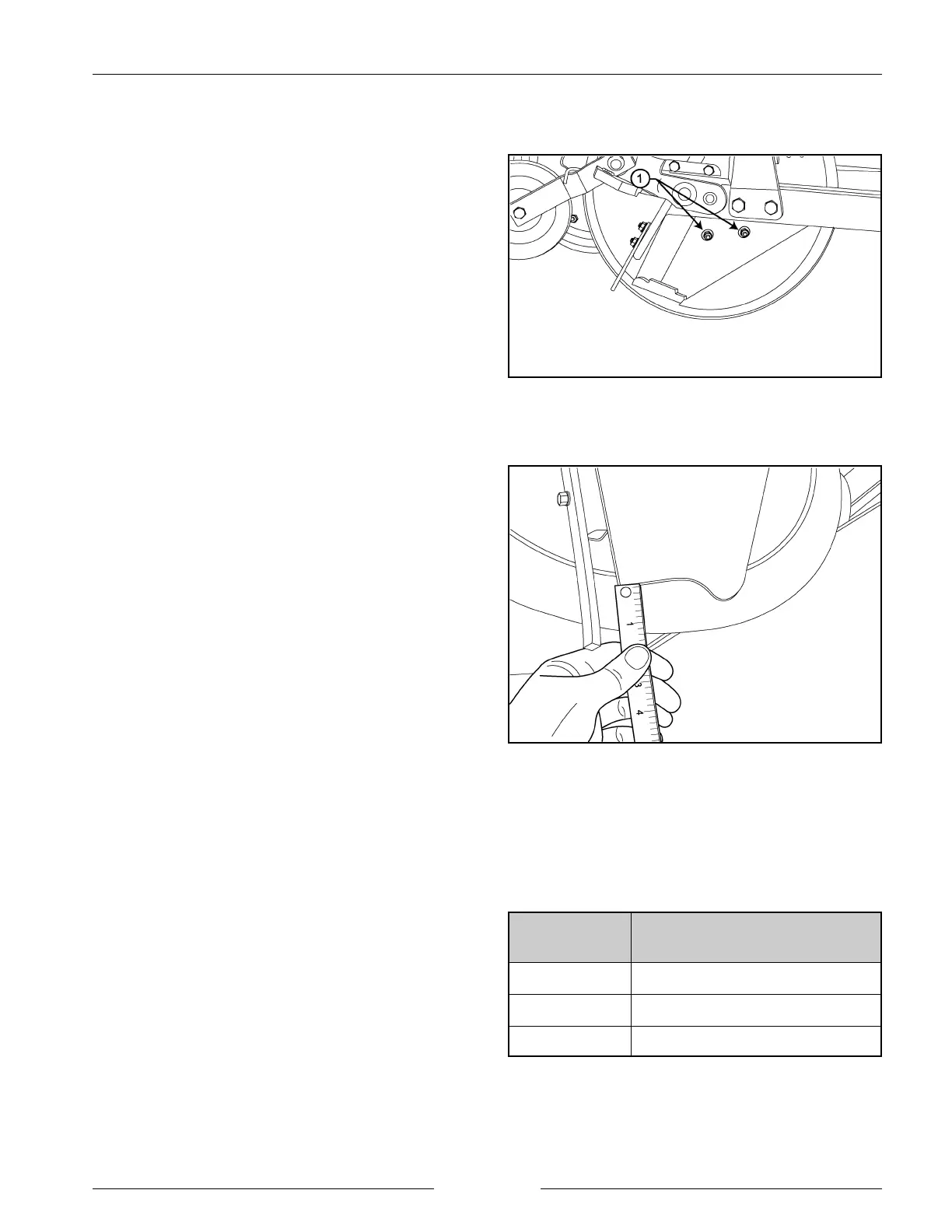

Check for Scraper Wear

202297S

SCRAPER ADJUSTMENTS

The scraper creates the opposite side of the seed trench to

the disk. The scraper is designed to be self-aligning, using

a spring behind the scraper to maintain contact between the

scraper and the disk.

1. The entire leading edge of the scraper should be in

contact with the disk.

- If it is not, adjust the tightness of the nuts holding

the scraper to the opener. DO NOT OVER-

TIGHTEN. Tighten the nuts until the bottom edge

of the scraper can be able to be pulled away from

the disk approximately 13 mm (1/2”).

2. When the bottom edge of the scraper has worn more

than 32 mm (1 1/4") above the bottom of the disk, the

scraper should be replaced.

NOTE: The scraper may wear at a different rate than

the disk blade.

- The maximum wear on the disk blade is 19

mm (3/4”) from the radius before replacement

is necessary.

- If scrapers are replaced prior to replacing disk

blades, a dimension less than 19 mm (3/4”)

may exist between the bottom of the scraper

and the cutting edge of the disk blade.

However, the scraper should not extend below

the disk blade.

- Therefore, if the distance from the bottom of

the new scraper to the cutting edge of the used

blade is less than 6 mm (1/4”), the disk blades

should also be replaced.

SCRAPER

CONDITION

MEASUREMENT*

NEW 19 mm (3/4”)

ACCEPTABLE 25 mm (1”)

REPLACE 32 mm (1 1/4")

* From bottom of trailing edge of scraper to cutting edge.

Loading...

Loading...