SECTION 6 - AIR SYSTEM SERVICE

page 6-8

Primary Hoses from Manifold to Implement

202070M1

Header and Secondary Hoses

202069M1

Inspecting the Header

202071M1

HOSES

When installing hoses, first measure them. Leave some

slack for folding and hose equalization and then cut and

install. Refer to the air package assembly manuals for

more detailed information on hose layout and assembly.

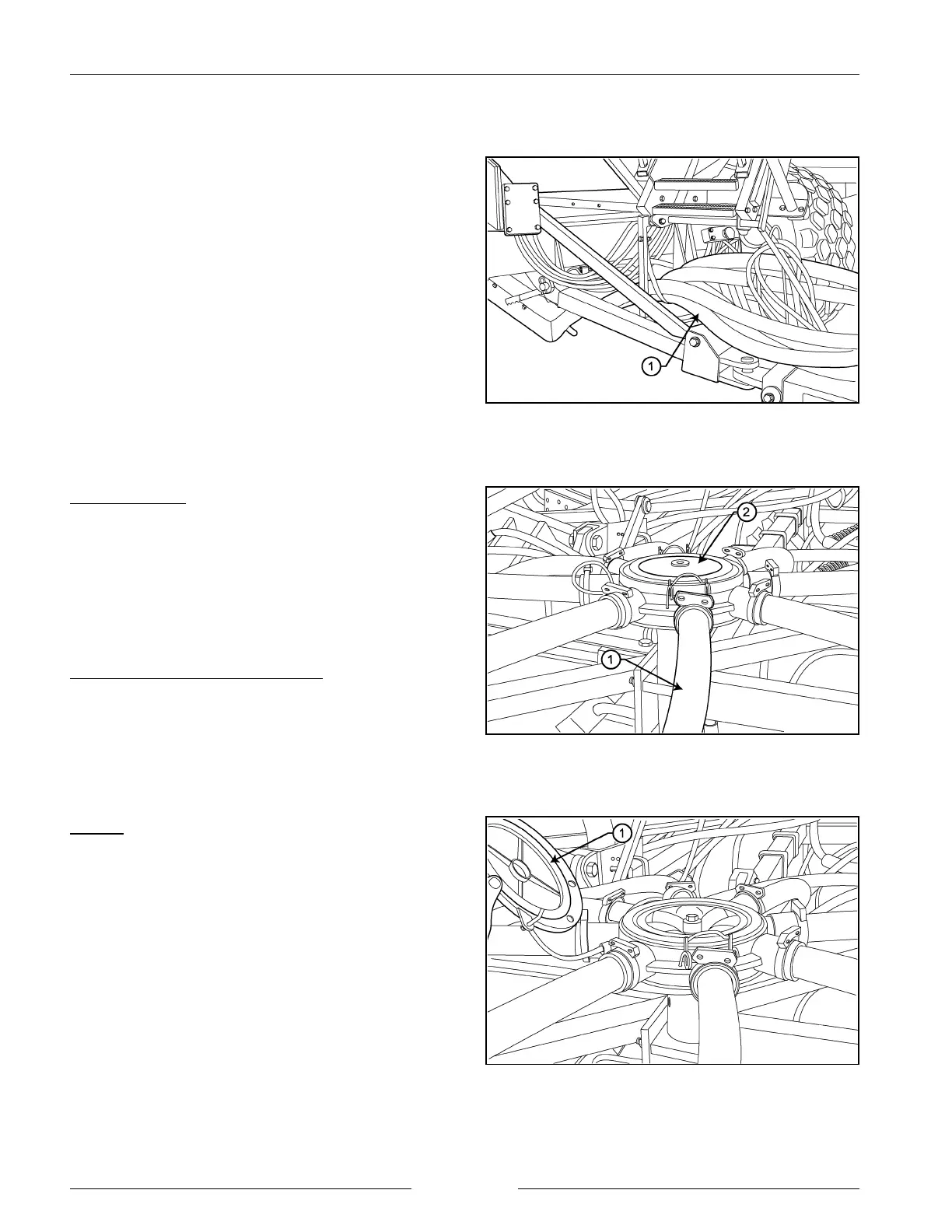

Primary Hoses - the 2 1/2" hoses (1) that run from the air

cart manifold to the headers on the implement.

When assembling an air pack, the longest hoses should run

from the inner section of the manifold (on the air cart) to

the outside headers on the implement. The length of the

hoses should be roughly equal, so there is even product

delivery. Primary hoses should be left slack and loosely

coiled to have even lengths. Hoses should be crossed at

the hitch connection so the hoses are not overlapping on

the implement.

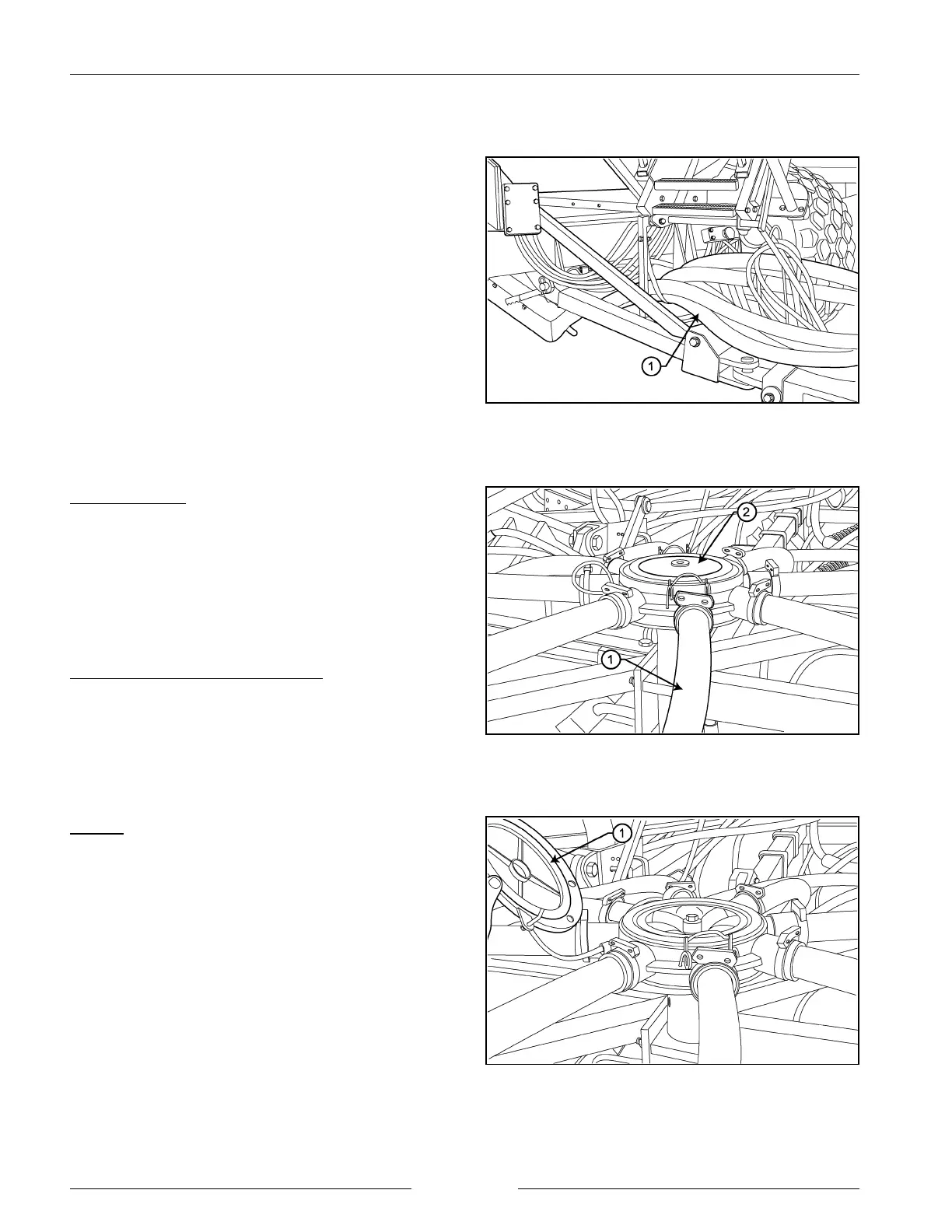

Secondary Hoses

- the 1" hoses (1) that run from the

header (2) to the openers.

When assembled, the hoses should be similar in length.

The longest hoses lead to the opener farthest away. Hoses

should be spiraled and gently sloped to the opener; avoid

having sharp bends in the hoses.

Attaching Secondary Hoses to Headers

- Secondary hoses

can be removed by twisting the clamp, pushing one side

towards the center of the manifold and pulling the other

tab back. This will release the clamps that hold the

secondary hoses in the manifold ports. Reattach hoses to

the header by squeezing the ends of the clamp together.

Headers

- headers need to be inspected for blockage.

Remove tops (1) for inspection. Check for wear.

Loading...

Loading...