SECTION 5 - OPENER SERVICE

page 5-3

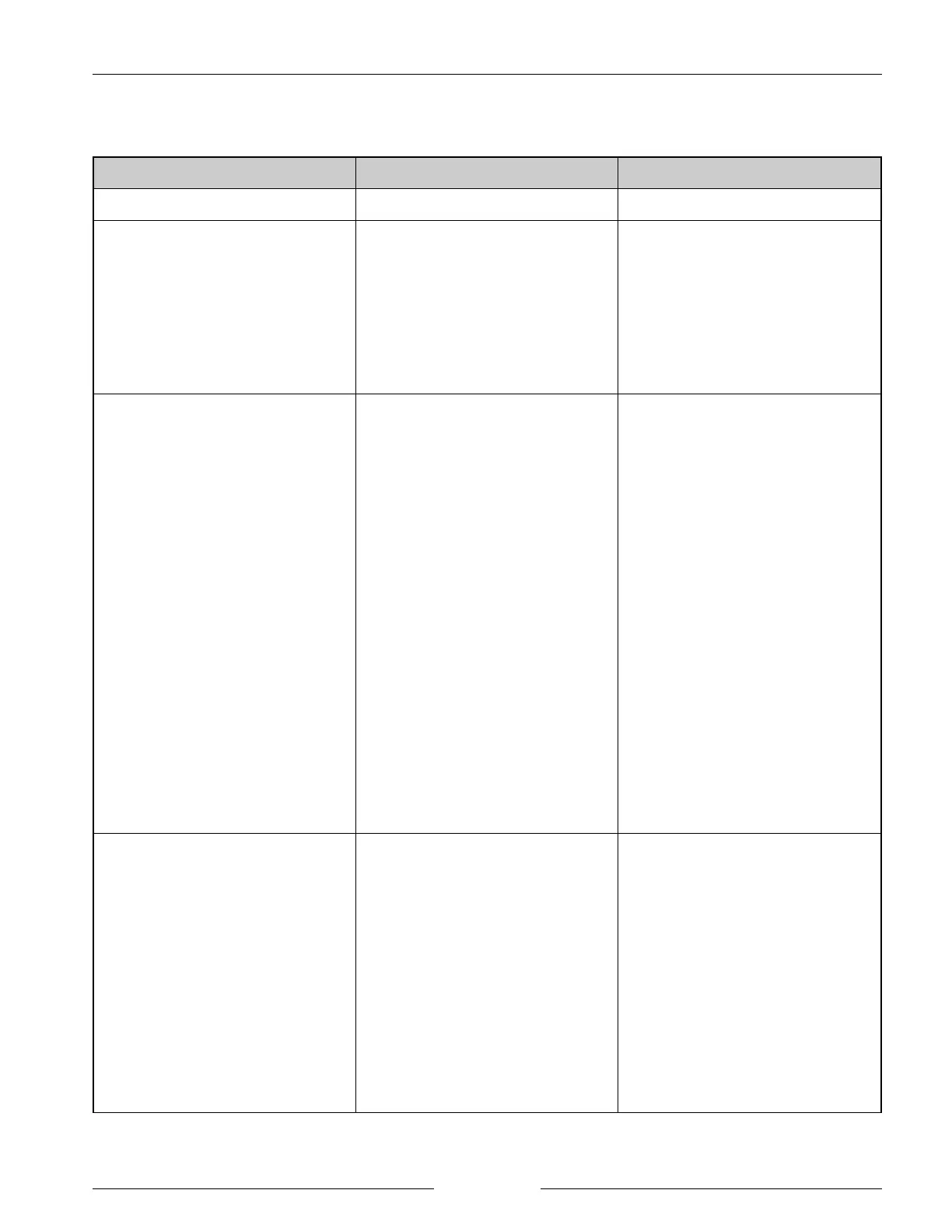

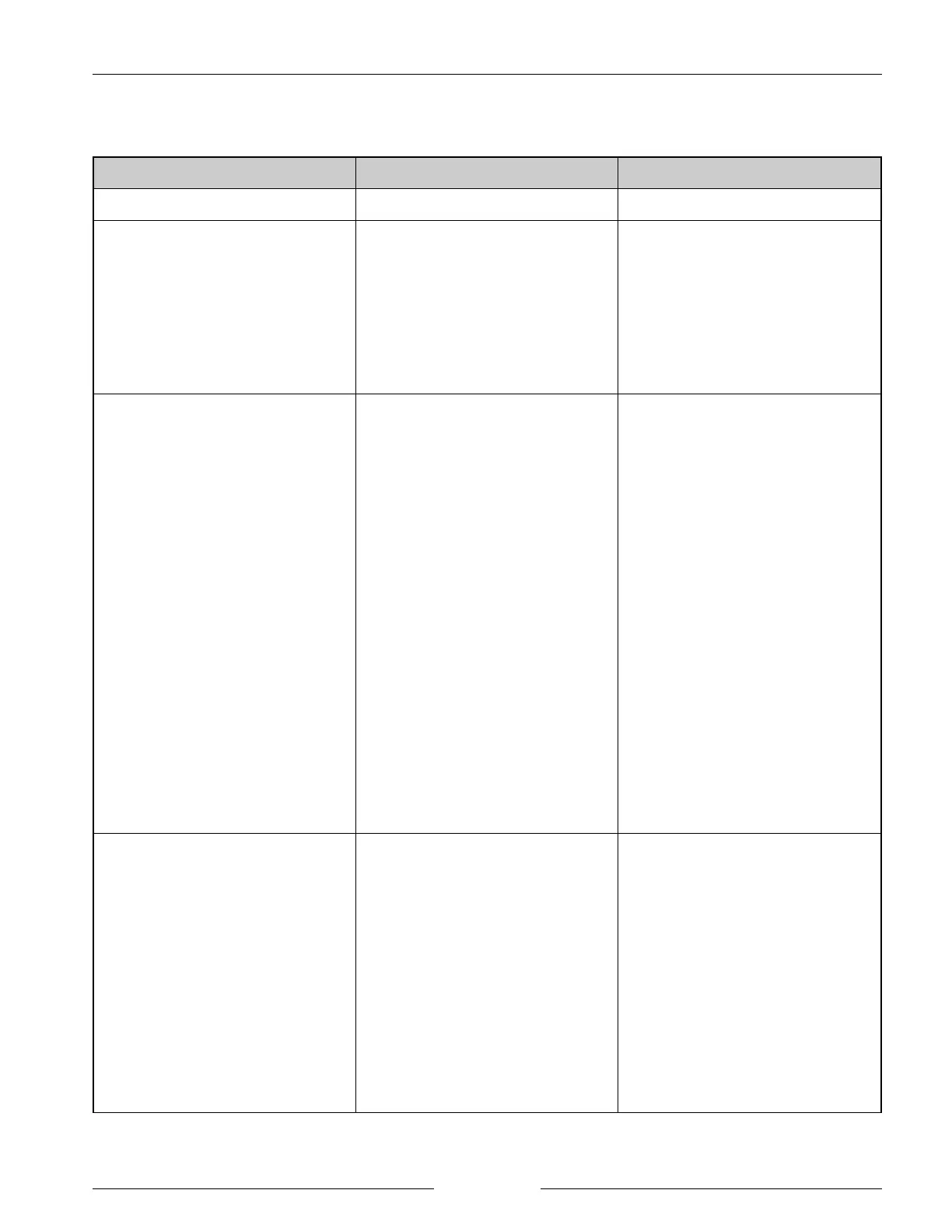

TROUBLESHOOTING TABLES

PROBLEM POSSIBLE CAUSES POSSIBLE SOLUTIONS

Excessive seed bounce in furrow. 1. Worn seed retention tab. 1. Replace tab.

Seeds sitting on the surface. 1. Inadequate disk penetration.

2. Broken/worn seed retaining tab.

3. Worn scraper.

4. Worn disk.

1. Increase disk penetration

adjustment.

2. Replace tab.

3. Replace scraper.

4. Replace disk.

Poor or uneven seeding depth. 1. High residue amounts.

2. Inadequate disk penetration.

3. Worn scrapers.

4. Inconsistent opener

adjustments.

5. Furrow not closing properly.

6. Mud buildup on gauge wheel.

7. Broken/worn seed retaining tab.

8. Worn disk.

9. Seed tab worn or broken.

1. Harrow residue to ensure even

distribution.

2. Increase disk opener down

pressure.

3. Replace scrapers.

4. Ensure consistent opener

adjustments.

5. Increase packing pressure.

and/or move side-to-side position

of packer wheel.

6. Wait for soil conditions to dry.

7. Increase disk penetration

adjustment.

8. Replace disk.

9. Replace tab.

Plugging of seed tubes. 1. Poor seed cleaning prior to use.

2. Wet fertilizer.

3. Backing up drill in the field.

4. Seed stuck in openers.

5. Seed build-up in openers.

6. Wet field conditions.

1. Use clean seed.

2. Use dry, high quality fertilizer.

3. Raise openers prior to backing

up.

4. Ensure openers are clean for

storage.

5. Ensure proper air flow rates from

air system.

6. Wait for soil conditions to dry.

Loading...

Loading...