SECTION 2 - MECHANICAL SERVICE

page 2-12

STORAGE

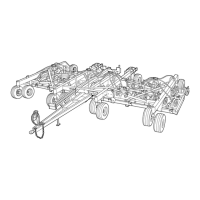

PREPARING THE DRILL FOR STORAGE

1. Store the machine in a dry place. Unfold the drill and

lower the disk openers to the ground. If the building

has a dirt floor, support the single disk openers on

boards to prevent the disks from entering the dirt.

2. Scrape or brush off any dirt on the machine and

remove all weeds and debris that may have wrapped

around the bearings and wheels. Before storing, apply

Til-coat (Part Number 1131548R2, available from your

dealer) to the surfaces of ground working tools. Apply

Case 251H-EP grease to hydraulic cylinder rods to

prevent rust.

3. Paint any surfaces that can rust.

4. Lubricate all grease fittings and each wheel hub.

5. Inspect the machine for worn or broken parts and

replace the parts as needed.

6. Check the air pressure in each tire and add air as

required. See Specifications in this manual for correct

tire pressure.

7. Do not let the tires sit in oil or grease or to come in

contact with manure or fertilizer, as these items will

destroy rubber tires. Fasten all hydraulic hoses to the

front hose support to keep the hose ends above the

ground.

REMOVING THE DRILL FROM STORAGE

1. Assemble any parts taken off for storage or

reconditioning and check for loose bolts and cotter

pins. Parts out of adjustment results in rapid wear,

possible breaking and poor operation. Check torque

on all opener bolts.

2. Lubricate the complete machine.

3. Check the air pressure in each tire and add air as

required.

Loading...

Loading...