SECTION 2 - MECHANICAL SERVICE

page 2-8

GREASE LOCATIONS AND GENERAL MAINTENANCE

IMPORTANT: Preventive maintenance, such as greasing the required locations at the correct times, making

the correct adjustments and greasing the machine thoroughly before storing will help to avoid

costly repairs.

Always use Case IH 251H-EP grease, available from your Case dealer in the following quantities:

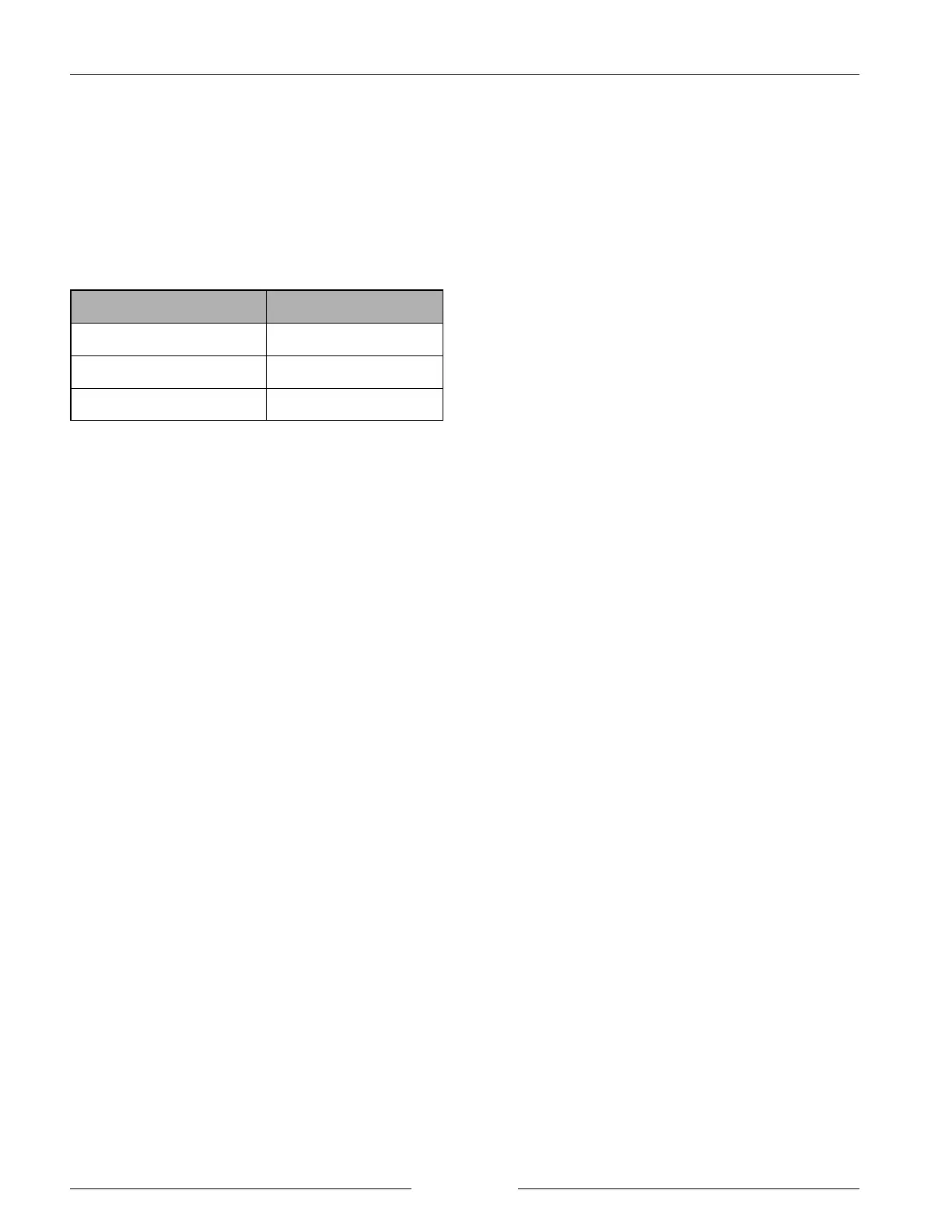

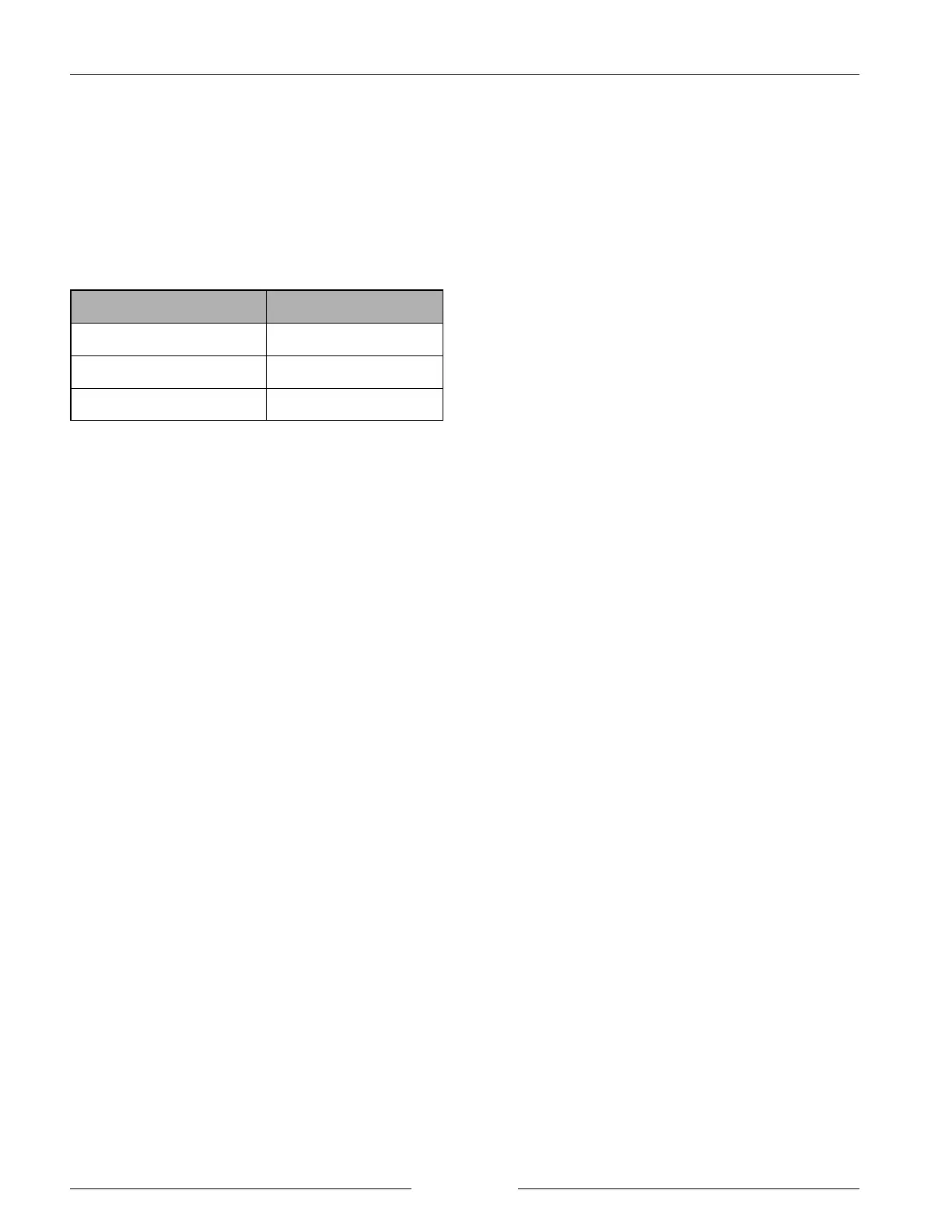

PART NUMBER QUANTITY

132096A1 14.5 ounce tube

132098A1 35 lb container

132097A1 120 lb drum

DAILY MAINTENANCE

Visually inspect the entire drill.

1. Check the hitch pin for a secure connection and make

sure the clevis or hammer strap is secure and in good

condition. Ensure that the safety chain is properly

connected. Refer to your Operator’s Manual.

2. Examine the hydraulic hoses and their connections for

leaks and abrasions.

3. Inspect all the wheel bolts for looseness. Torque wheel

bolts after the first ten hours of operation and

frequently after that. Refer to the Specifications

Section for wheel bolt torques.

4. Look down the rear of the drill for damaged openers.

5. Clean the Slow Moving Vehicle Sign.

6. Inspect all hitch pins, pivot pins, and frame

components for signs of wear.

Loading...

Loading...