SECTION 7 - ENDMARKER SERVICE

page 7-3

DANGER!

ENDMARKERS

SAFETY DURING OPERATION

Stand clear of implement when end marker is

being folded or unfolded. Disc blade on end of

boom swings out fast and covers a large area.

Failure to follow these instructions will result in

death or serious injury.

ALWAYS be certain that no one is behind or around

implement while operating hydraulics.

DO NOT RIDE

on implement during operation.

BE SURE

reflector decals are clearly visible from all sides

of implement and the Slow Moving Vehicle sign is at the

rear of implement in clear view of overtaking traffic. Five

section implements with tow between seeders require

SMV sign on the end of marker boom near disc.

BE AWARE

of overhead electrical lines. Proceed

cautiously under overhead electrical lines and around

utility poles. Electrocution can occur without direct

contact with overhead electrical lines.

ALWAYS

fold endmarkers in before putting implement

into transport.

ALWAYS

have implement in field position before folding

out endmarker.

AVOID

hitting obstacles with endmarker.

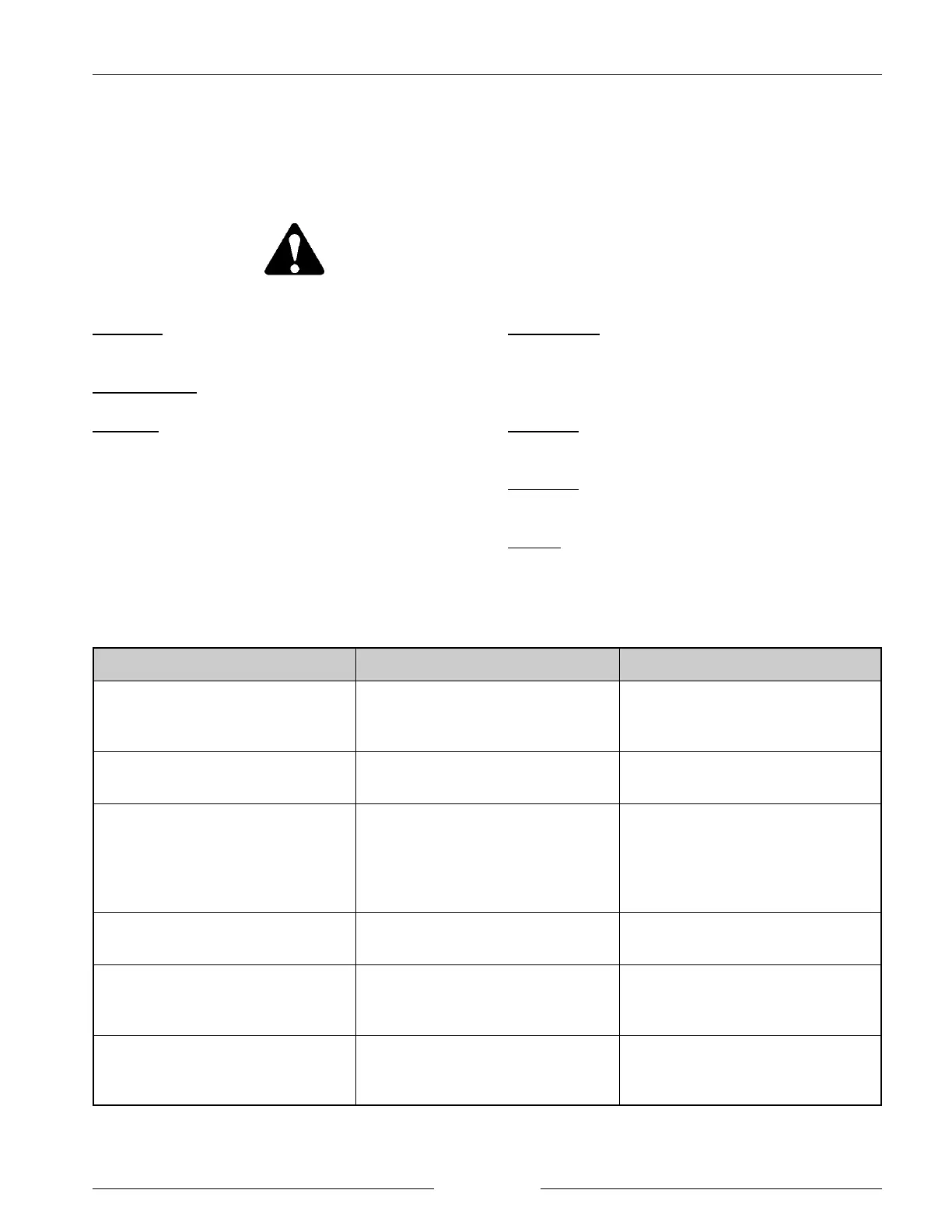

TROUBLESHOOTING TABLE

PROBLEM POSSIBLE CAUSES POSSIBLE SOLUTIONS

Mark not visible. 1. Marker not adjusted properly. 1. Adjust marker disc so that it

cuts more aggressively.

Mark too aggressive. 1. Too much angle to the disc. 1. Adjust marker so that the disc

cuts less aggressively.

Marker disc gouging on corners. 1. Marker in ground on corners. 1. Marker can handle gentle, well-

rounded corners. For a sharp

corner where the inside boom

reverses, the marker should be

raised out of the ground.

Disc is vibrating excessively. 1. Bearings may be worn or loose. 1. Replace bearings.

Disc does not turn freely. 1. Debri s w rapped around

spindle.

1. Remove debris ( e.g., weeds or

twine).

Marker arms flop to lower position. 1. Hydraulics not assembled

correctly.

1. Refer to the hydraulic

schematic for the marker.

Loading...

Loading...