SECTION 5 - OPENER SERVICE

page 5-9

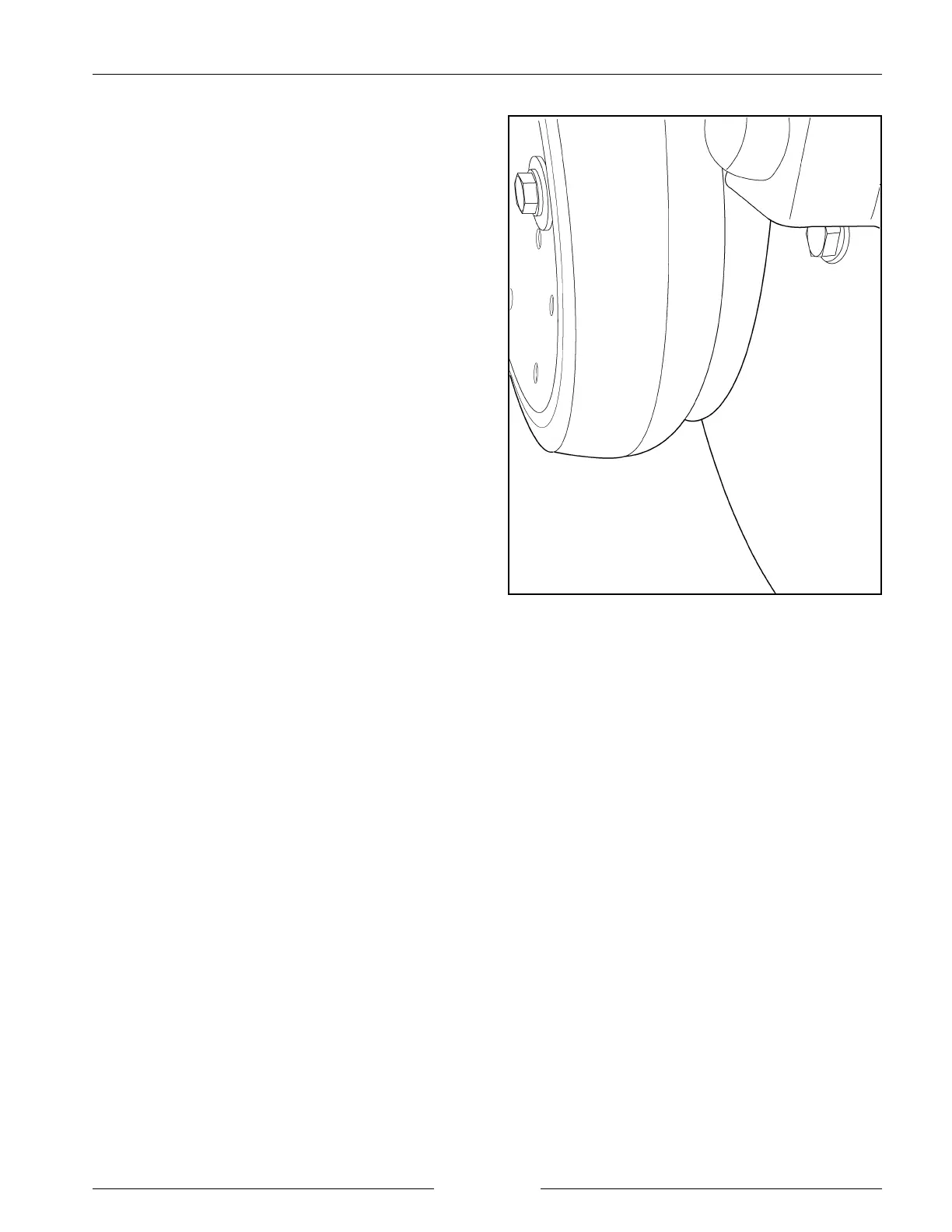

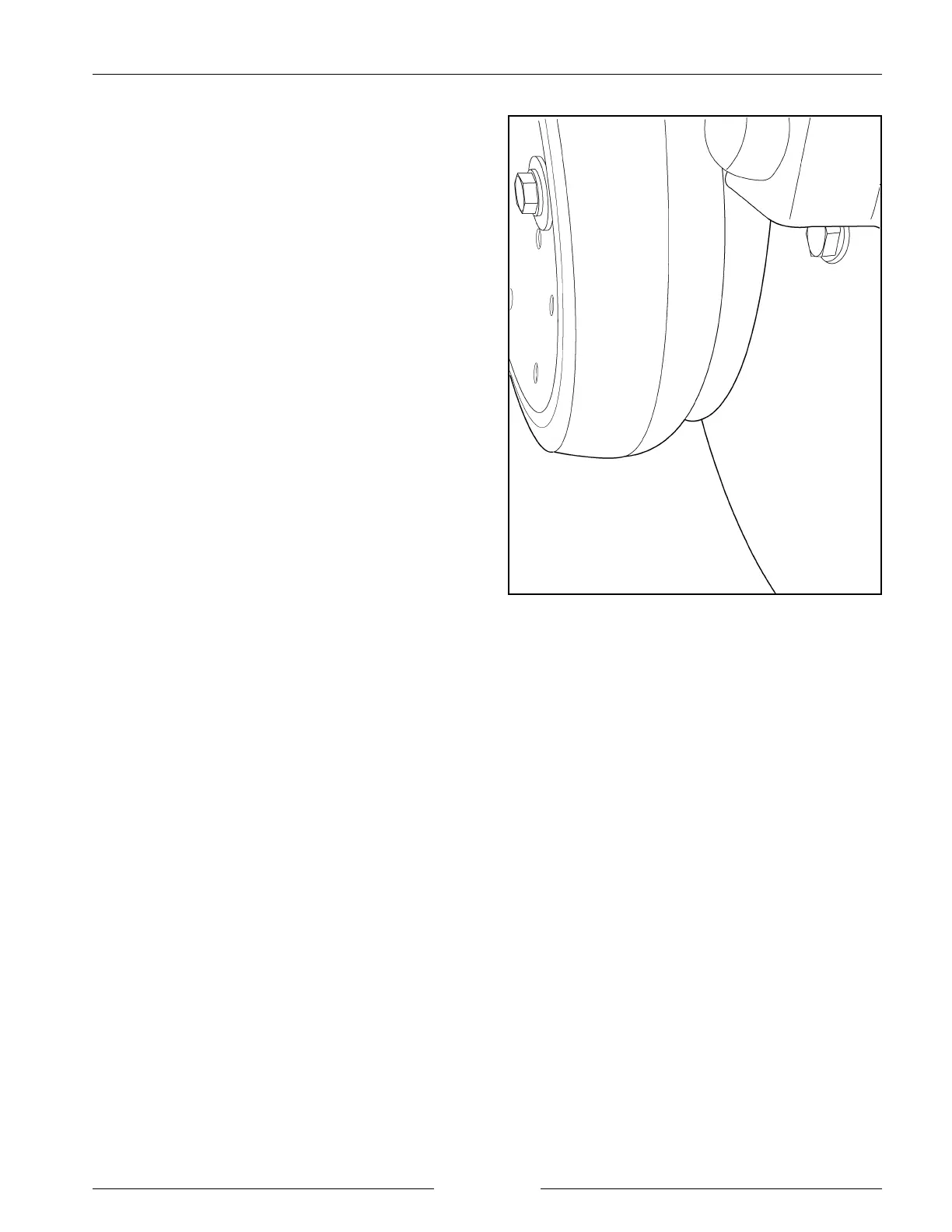

Check Gauge Wheel Gap

202299S

2. The gauge wheel also removes soil build-up on the

disk. Therefore, the gap between the disk and gauge

wheel is very important.

- If the gap is too wide, the wheel will plug with

mud or residue. The gap between the gauge wheel

and the disk should be between lightly touching to

3 mm (1/8").

- As the gauge wheel wears, spacers between the

gauge wheel and gauge arm may need to be

removed to maintain the proper gap.

- When the gap becomes more than 3 mm (1/8") and

there are no more washers to remove, the gauge

wheel must be replaced.

- Apply thread locking compound to the gauge

wheel bolt when reassembling the gauge wheel to

the opener.

In conditions where heavy residue exists, the disk may

require deeper setting to achieve the desired seeding

depth. Disk wear may result in changes in seed

placement. Seed placement should be regularly

checked in the field to ensure proper seeding

operation.

Tighten all gauge wheels after the first 90 ha (200 ac)

of use and periodically throughout the season as

recommended.

Loading...

Loading...