9 Electronic Cam

DVP-20PM Application Manual

9-29

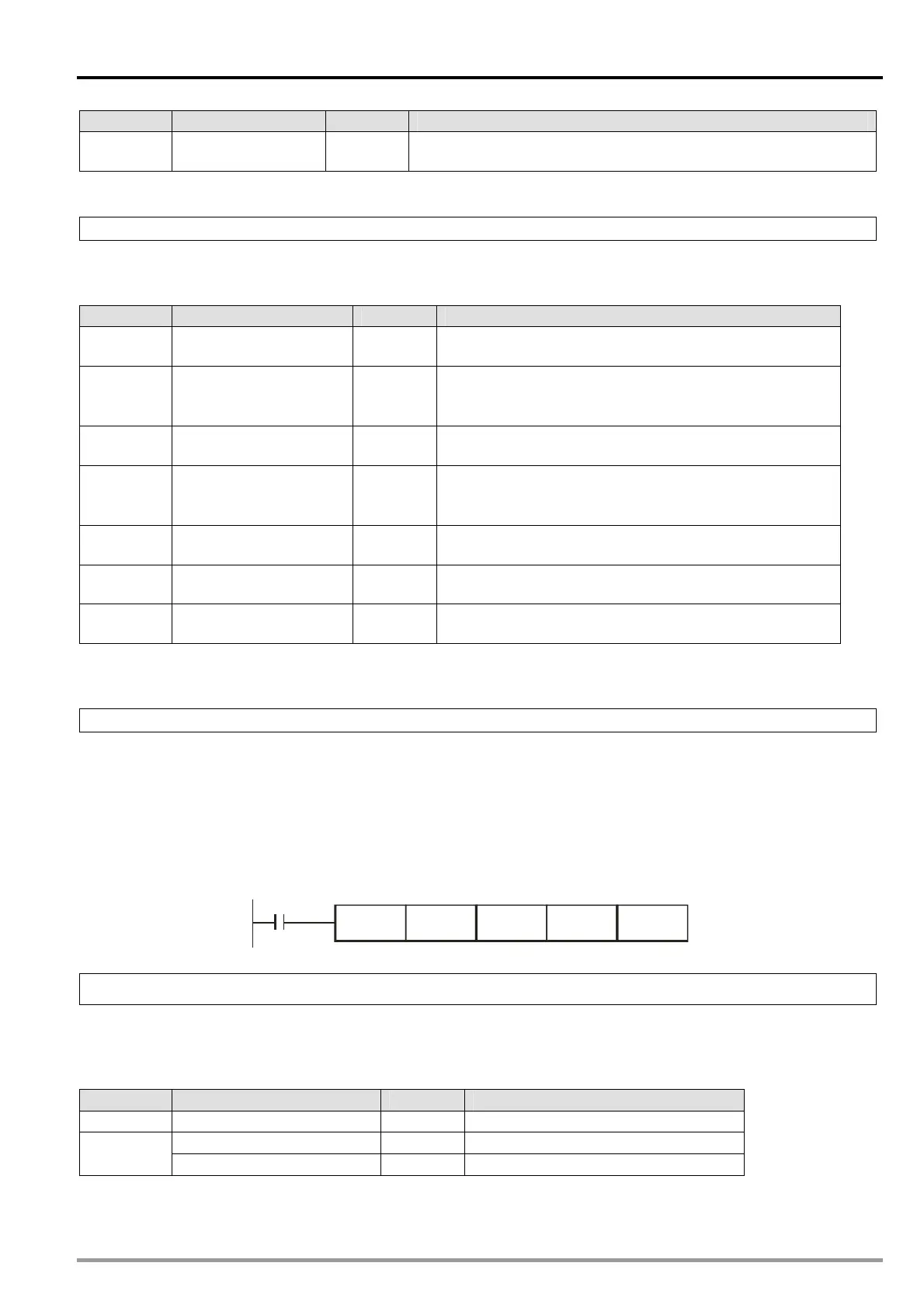

Parameter Data Format Explanation

P12

Number of data

points in sync area

Integer

When b[2] of P1 is 1, the parameter sets the number of data

points in sync area.

For detailed explanation of creating thick material cutting electronic cam curves, please refer to 9.4.2.4.

CR#10001: Reading electronic cam status

[Description]

The function is used to read current electronic cam status when electronic cam is executing. Only

DFROM instruction is applicable for this function. The read data will be as shown below.

Parameter Data Format Explanation

P1

Current position of

Master

Integer Reset at DOG signal

P2 Length of Master 1 Integer

DOG signal to DOG signal

Single cam: Length of the master axis after the

triggering of DOG

P3

Current electronic cam

curve

Integer

P4

Current position of

Slave

Integer

Updated at DOG signal

Single cam: Present length of the master axis after the

triggering of DOG

P5 Error of Slave Integer

Error between DOG signal and the end point of CAM

cycle.

P6

Current position of

Master

Integer START0/PG0 signal to START0/PG0 signal

P7 Error of Master Integer

Error between START0, PG0 signal and the end point of

CAM cycle

The function of reading electronic cam status can be applied in offset compensation to Slave error. For

the methods of Slave error compensation, please refer to 9.4.2.5.

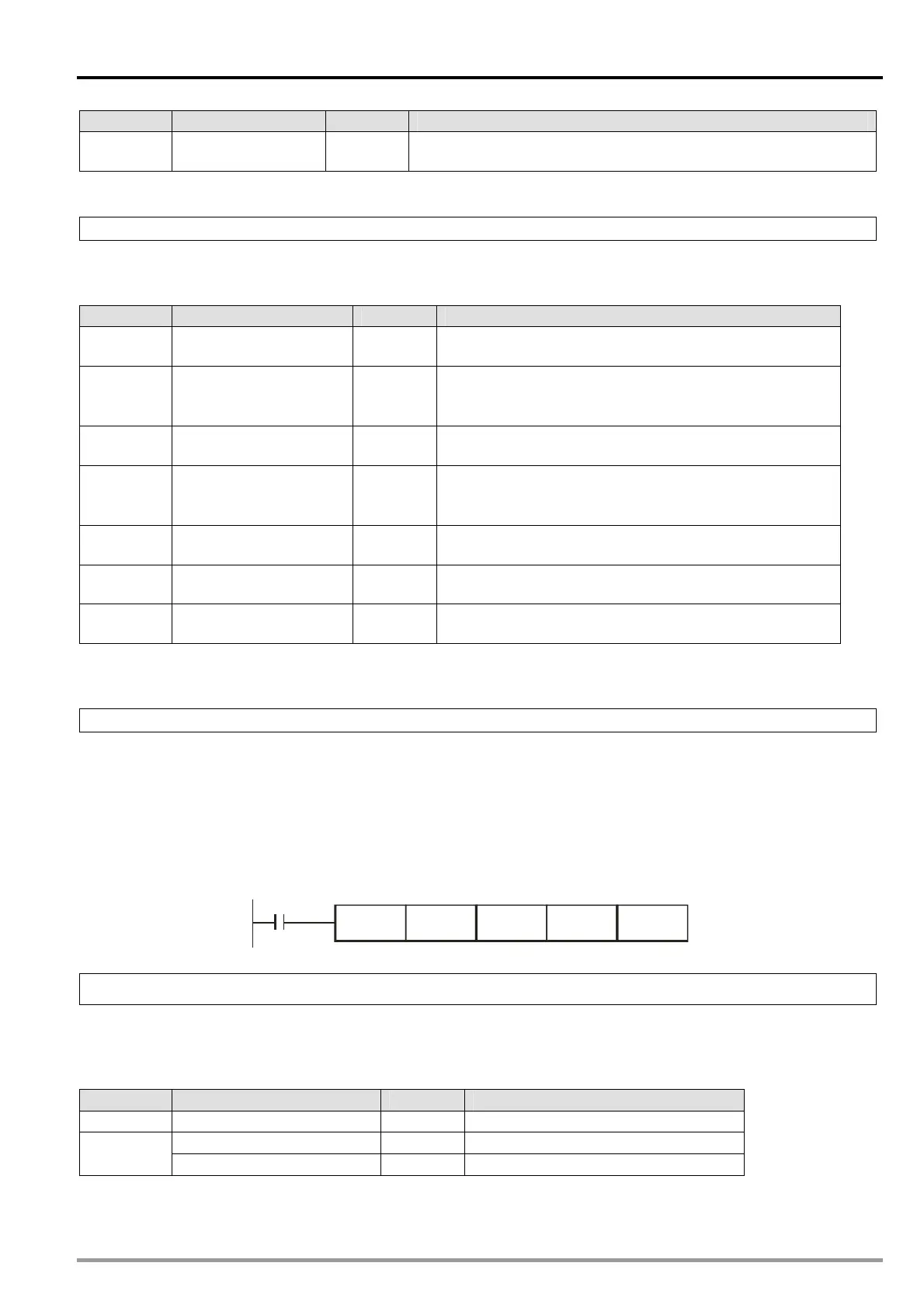

CR#10002: Electronic cam chart real-time change

[Description]

There are 3 built-in electronic cam charts in PMSoft: Electronic cam chart-0~electronic cam chart-2. If

users need to conduct real-time change of electronic cam chart during program execution, set up this

register to designate the electronic cam chart to be enabled in the next cycle. Care should be taken on

the number of electronic cam charts, which should be as least 2 sets available for the change. The

instruction below is the application example. Set D0=K10002 before the electronic cam chart real time

change. When X0=ON, set value (0, 1, 2) in D100 indicating the cam chart to be selected (electronic

cam chart-0~electronic cam chart-2) will be written into DVP-20PM.

X0

DTO K100 D0 D100 K1

CR#10003: Smooth curve interpolation

[Description]

When the original data points are not sufficient for a smoother operation, users can apply Smooth

Curve Interpolation. The detailed content of smooth curve interpolation will be explained in 9.4.2.2.

Parameters for setting up the function are listed as below.

Parameter Data Format Explanation

P1 Maximum length of Master Integer

Original data points Integer

P2

Total points to be inserted Integer

Loading...

Loading...