9 Electronic Cam

9.6.3.1 Operati

on of a Flying Shear

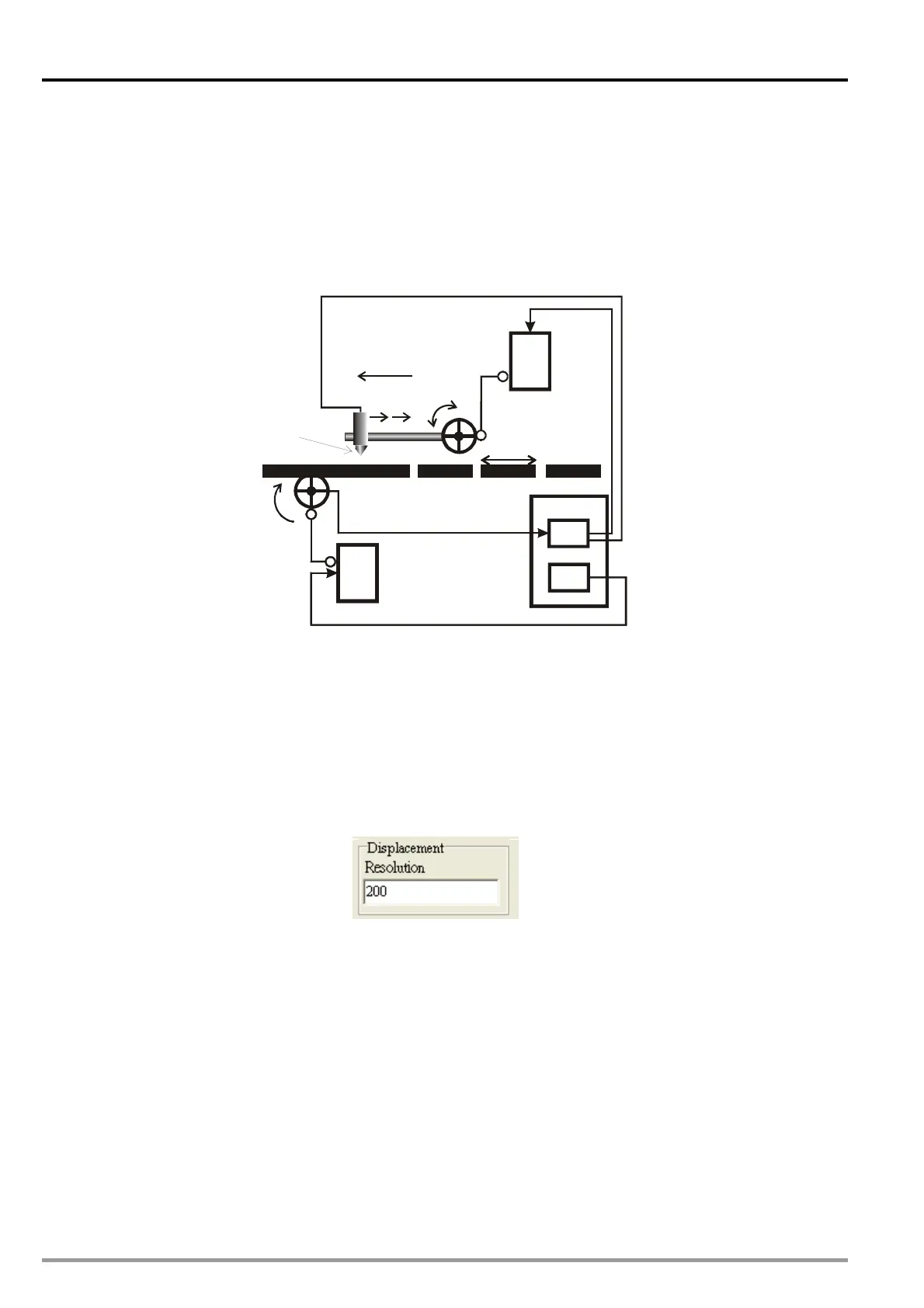

The operation and simple wiring of flying shear is illustrated as below. Positions 1, 2, 3 and 4

respectively indicate starting position, sync-start position, sync-end position and ready position. When

Master (Y axis) executes, Slave (X axis) accelerates from position 1 to position 2, reaching the

synchronizing speed. The sync speed is maintained from position 2 to position 3. After position3, Slave

decelerates in reverse direction and returns to position 4 (Same as position 1). The cycle repeats for

continuous flying shear operation.

SERVO

SERVO

20PM

CAM

X axis

Y axis

Jog

Encoder output

Cut Length

SERVO

CAM

Jog

Cut Length

SERVO

20PM

CAM

X axis

Y axis

Jog

Encoder output

Cut Length

SERVO

CAM

Jog

Cut Length

123

SyncOut

blade

4

9.6.3.2 Creating an Electronic Cam Curve

In electronic cam design process, PMSoft creates electronic cam data by operating displacement data

to generate the velocity data and the acc data. However, in this case users need to control the velocity

between Slave and Master. To obtain the velocity, users can input the velocity data in the displacement

table for creating the velocity curve. After the velocity curve is created with displacement and acc curve,

export the velocity data by clicking “Export” and import the velocity data by clicking “Import Speed Data”,

so that the velocity relationship between Slave and Master can be obtained.

1. Set the max resolution as 200.

DVP-20PM Application Manual

9-60

Loading...

Loading...