10 Application of G-codes

DVP-20PM Application Manual

10-17

The program in O100 is as figure (B).

es of three axes are set.

N, the data in OX0 is loaded into CAM chart-0.

he data source is in CAM chart-0)

s

corresponding CAM chart, and only G00, G01, G04 and

Step 1: When M1 is ON, the work mod

a. D1847=H1000

b.

D1927=H1000

c. D2007=H1000

Step 2: When M2 is O

a. When the value in D1868 is H400, Ox0 is selected.

b. Load the data in OX0 into CAM chart-0.

Step 3: When M7 is ON, Ox0 is executed. (T

a. When the value in D1868 is H4000, cam chart 0 is selected.

b. Enable cyclic electronic cam.

10.4 Storing G-codes/M-code

In this function, data in OXn is loaded to the

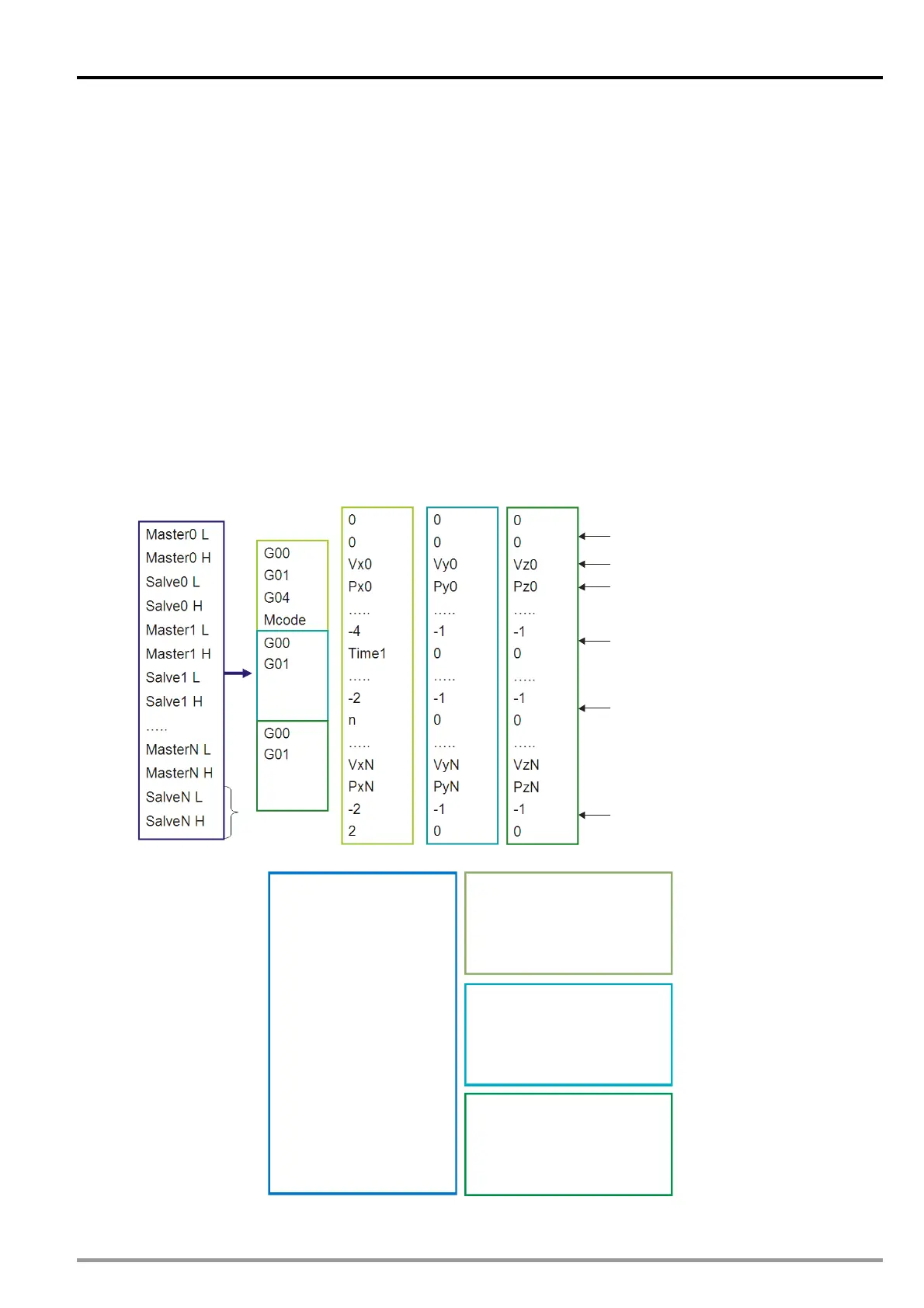

M-codes applied in “With mode” are supported for this function. The below diagram explains the data

allocation in CAM chart.

Arrangement of CAM data (16-bit)

(X-axis)

(X-axis)

(Y-axis)

(Y-axis)

(Z-axis)

(Z-axis)

32-bit

floating-point

value

X-axis

Y-axis

Z-axis

Start of an Ox motion subroutine

Velocity: G0. G1

Displacement

G04

Mn

M02 (End of the Ox motion subroutine)

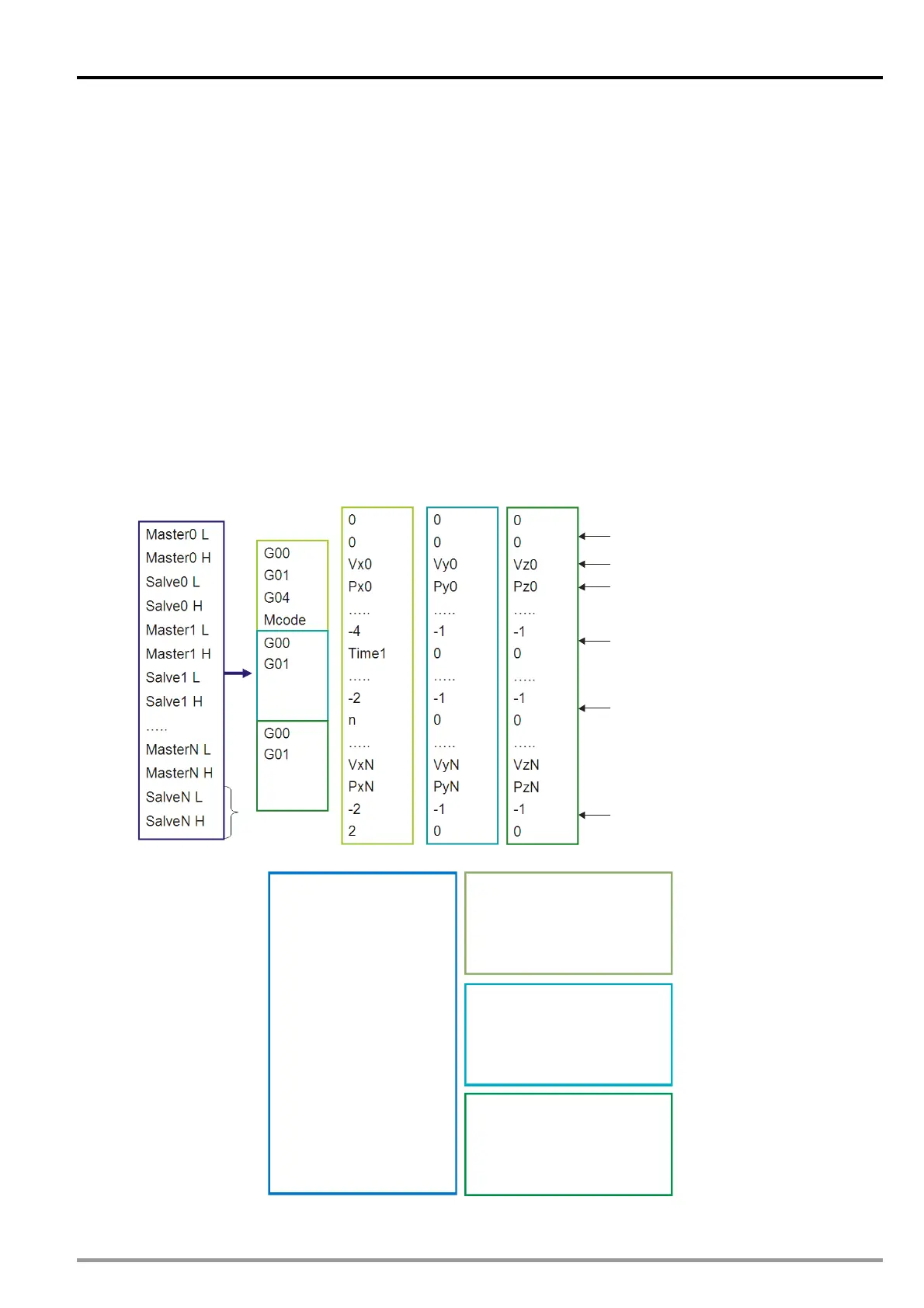

Arrangement of data after the reading of the data (16-bit)

0

499

Start0=0

n0=500

CAM chart

X-axis

Y-axis

Z-axis

500

999

Start1=2000

n1=500

1000

1499

Start2=4000

n2=500

Resolution

n=1500

Loading...

Loading...