10 Application of G-codes

DVP-20PM Application Manual

10-18

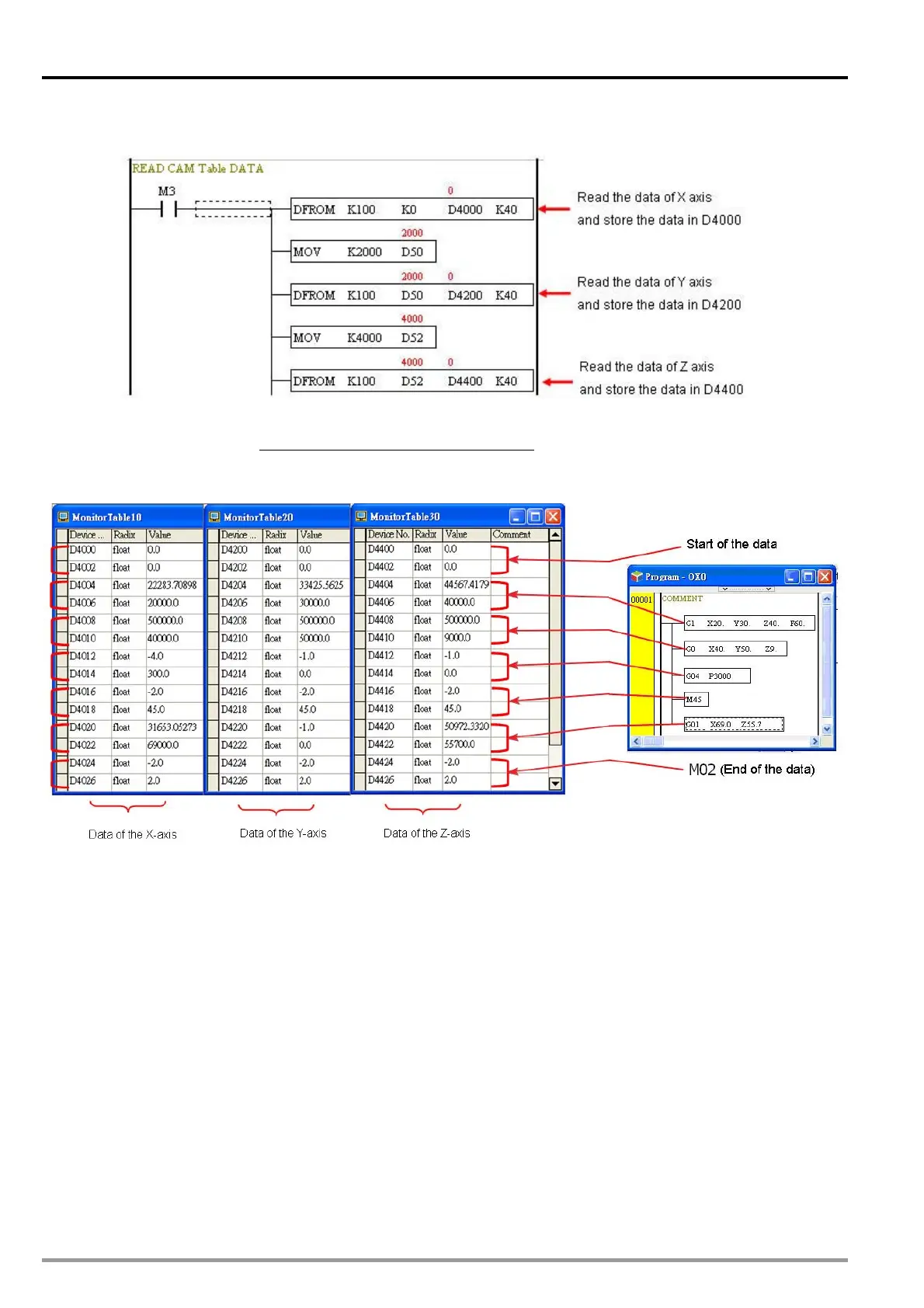

he example program uses CAM chart-0 with max resolution 1500. The below program are applied for T

reading the data of 3 axes in CAM chart.

P.S.: Note: In the instruction DFROM (DTO) K100 K0 D4000 K40, K100 indicates access in CAM

chart-0. If K101 is set, it indicates access in CAM chart-1. If K102 is set, it indicates access in

CAM chart-2.

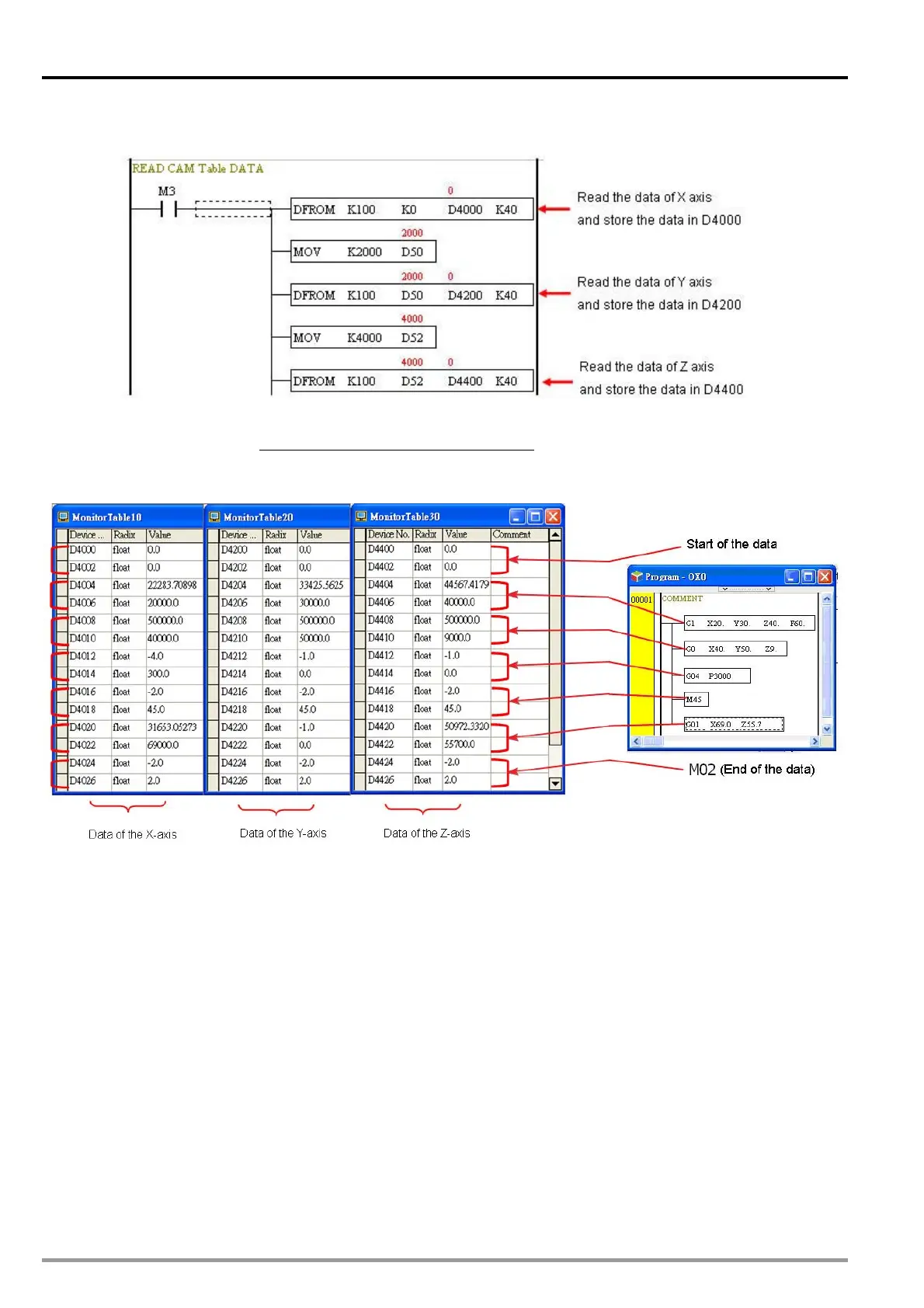

Conclusions drawn from the data above:

he lower data is position. “-1” will be set if the speed data is not

d data is fixed as 500K. The lower data is position. “-1” will be set if the speed data is not

0/G01: Write -1 into the speed data of G00/G01 on specific axis, and the instruction on

a indicates G04. The lower data is pause time. Unit: 10ms.

aced in all axes.

1. The first data of each axis is 0.

2. G01: The upper data is speed; t

specified.

3. G00: Spee

specified.

4. Stopping G0

the axis will be stopped.

5. G04: The value -4 in upper dat

6. M-code: The value -2 indicates an M-code. The lower data is an M-code number.

7. End of the data: -2 and 2 indicates M02, which is the end of the CAM data.

8. G04 can only be placed in X axis.

9. An M-code instruction should be pl

Loading...

Loading...