9 Electronic Cam

High speed winding on master shaft and slave shaft can be performed by executing single speed

positioning on winding device (3), together with electronic cam operation on coil device (4). Other

operations are similar to general sequential ladder control and can be executed by general functions of

PLC.

The movement of winding shafts and coil shafts are explained as below. The coil shaft (Slave) follows

the winding shaft (Master) and reciprocates within the range of single layer in certain proportion with

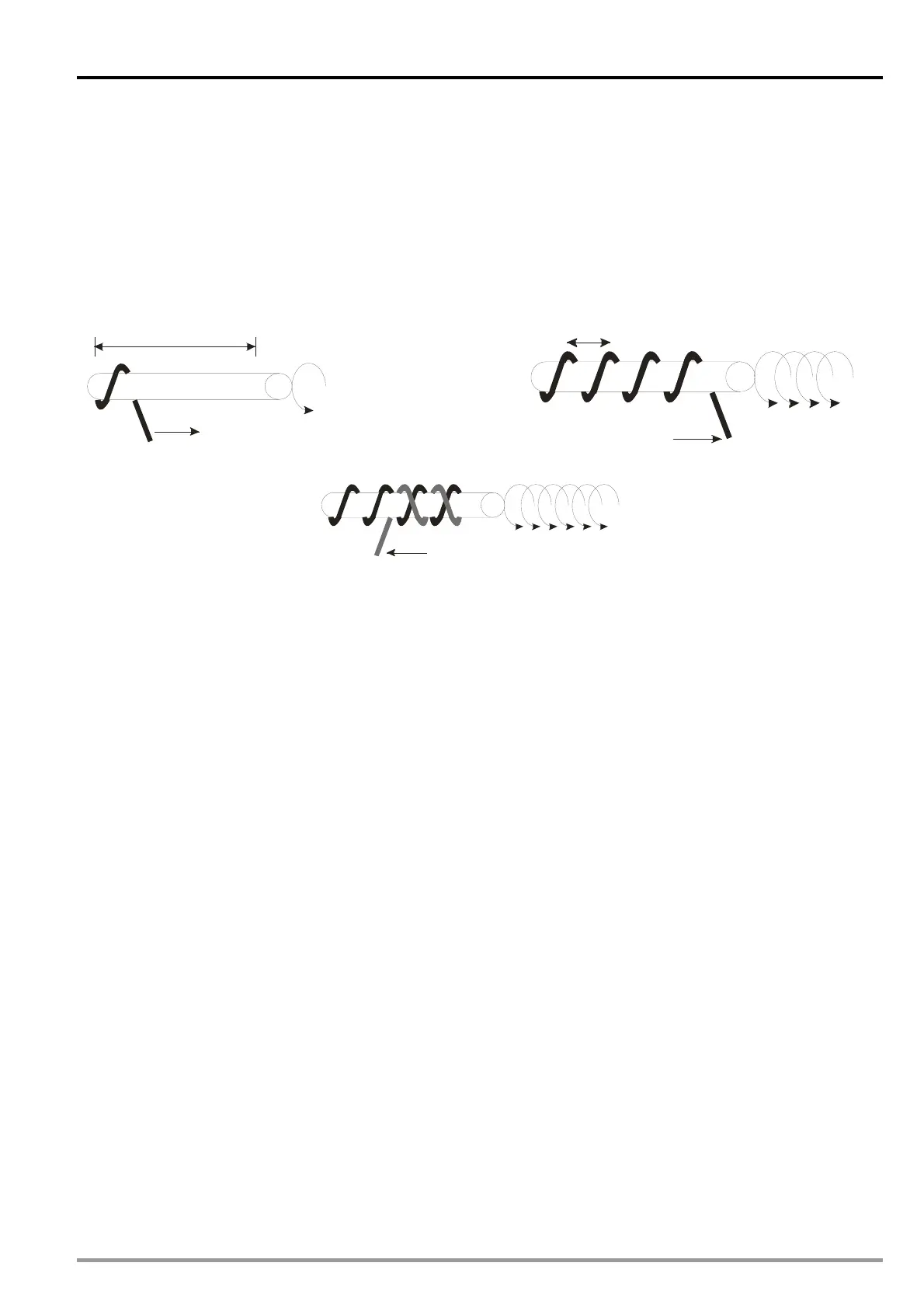

winding shaft. At the beginning, Slave starts at the left end and moves one coil space as diagram (A).

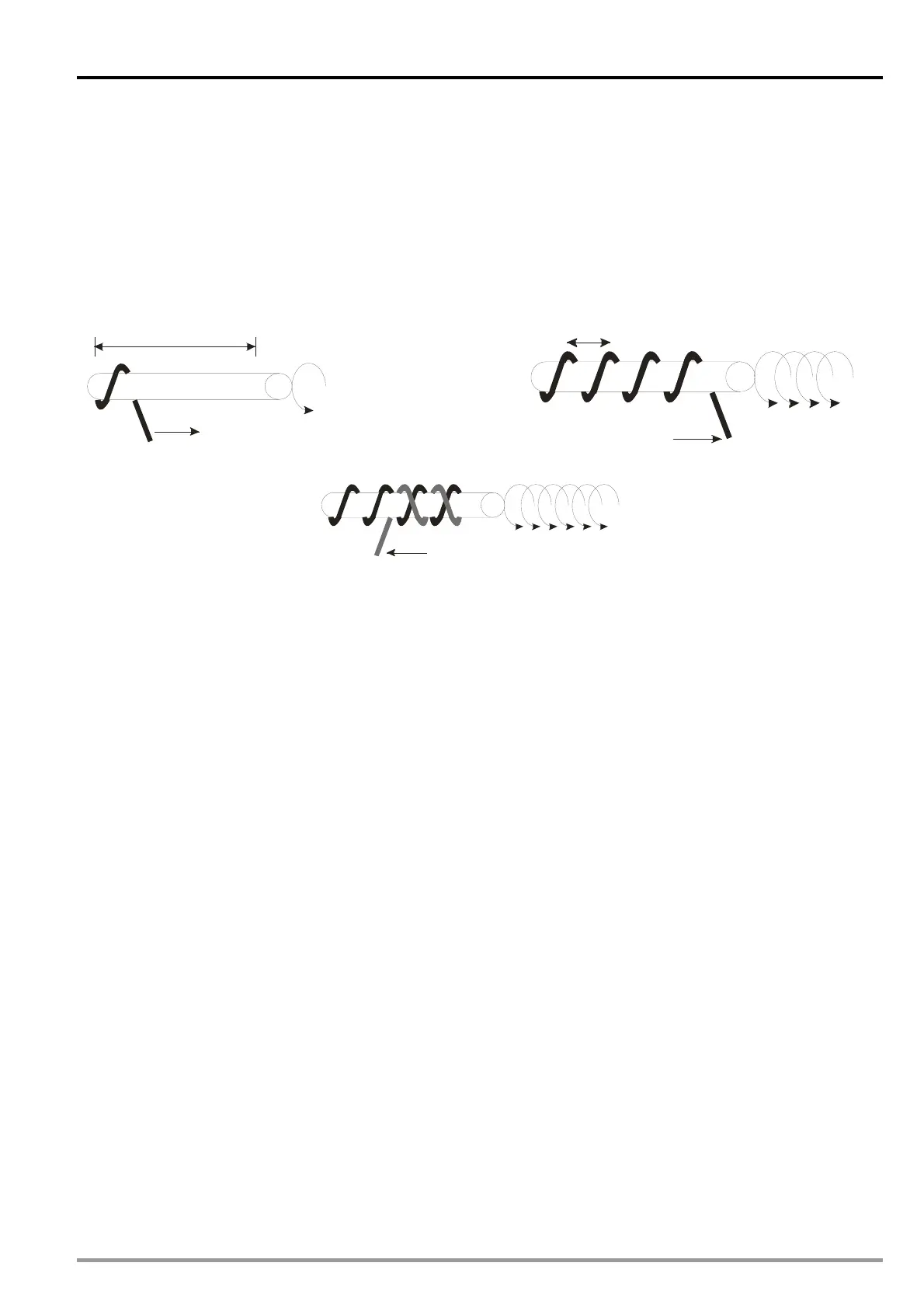

When Slave moves to the right end of the single layer range as indicated in diagram (B), the moving

direction of Slave reverses as diagram (C). When Slave reaches the left end of single layer range, the

moving direction of Slave reverses again.

Range(rounds) of single layer

(A)

Total rounds of winding

Coil spacin

(B)

(C)

From the above winding movements, there are 3 major input parameters: 1. rounds per layer, 2. total

rounds of winding, and 3. coil spacing (The value of coil spacing is calculated by adding coil diameter

with the space between each round). In addition, Mechanical parameter (mm/pulses) is required for

obtaining the Master/Slave (winding shaft/coil shaft) proportion. Mechanical parameter consists of

mechanism parameter and servo parameter. Mechanism parameter is the moving distance per round

(mm/revolution) and servo parameter is the pulses per round (pulses/revolution) obtained by multiplying

the electronic gear ratio. Mechanism parameter (mm/revolution) divided by servo parameter

(pulses/revolution) equals the mechanical parameter (mm/pulses). After the parameters are ready,

apply cyclic electronic cam on X axis (Slave) because the coil shaft reciprocates cycle by cycle, and

single speed positioning on Y axis (Master) because the winding shaft moves on in the same direction.

DVP-20PM Application Manual

9-53

Loading...

Loading...