9 Electronic Cam

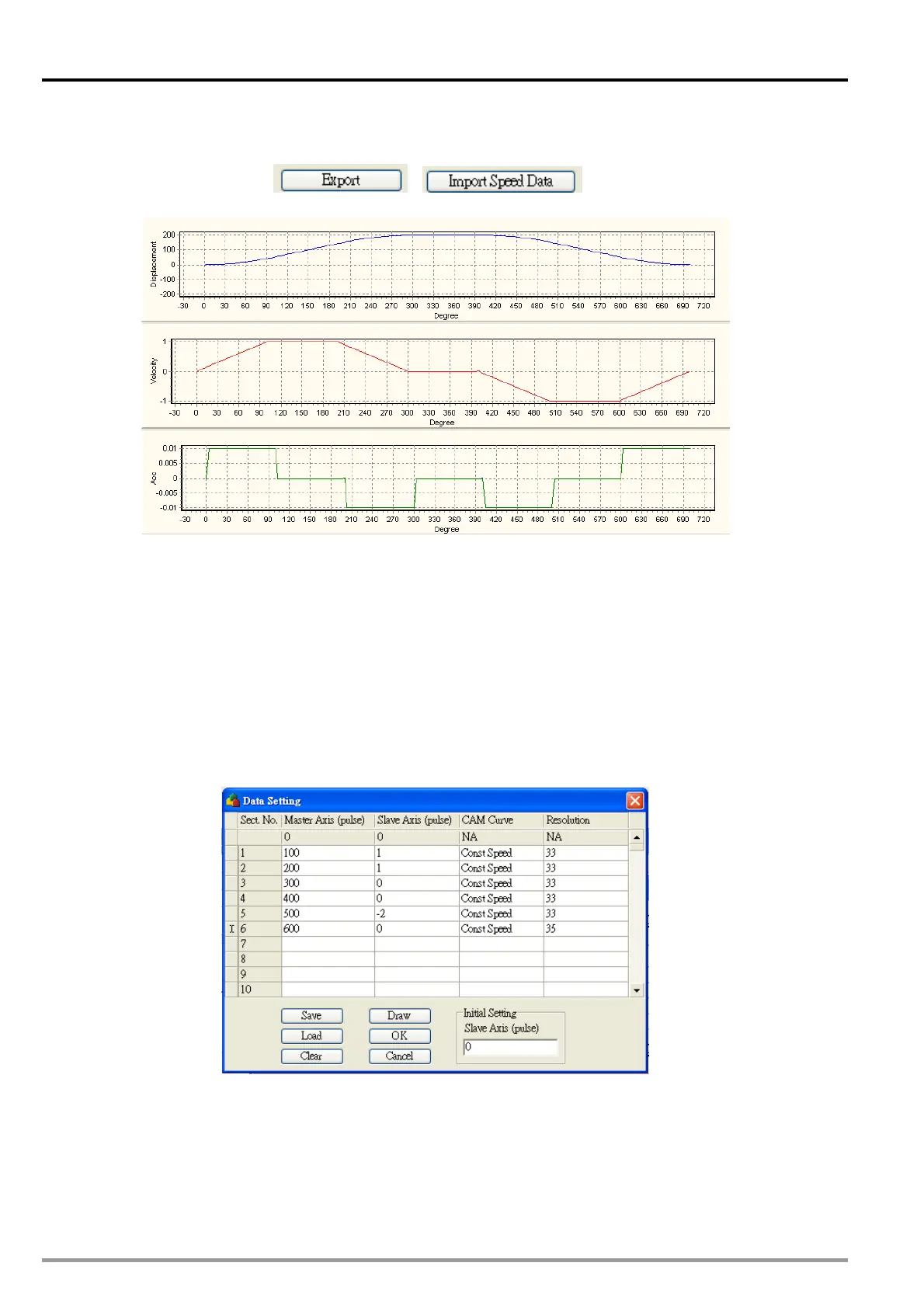

3. Click “Export” then “Import Speed Data” and the velocity relationship between Slave and Master can

be obtained.

According to the above electronic cam chart, users can calculate the pulses per round of Slave

(Slavemax=200) by the square measure of velocity data.

Positive square measure:

(1*100/2+1*(200-100)+1*(300-200)/2)=200

Negative square measure:

((-1)*100/2+(-1)*(200-100)+(-1)*(300-200)/2)=-200

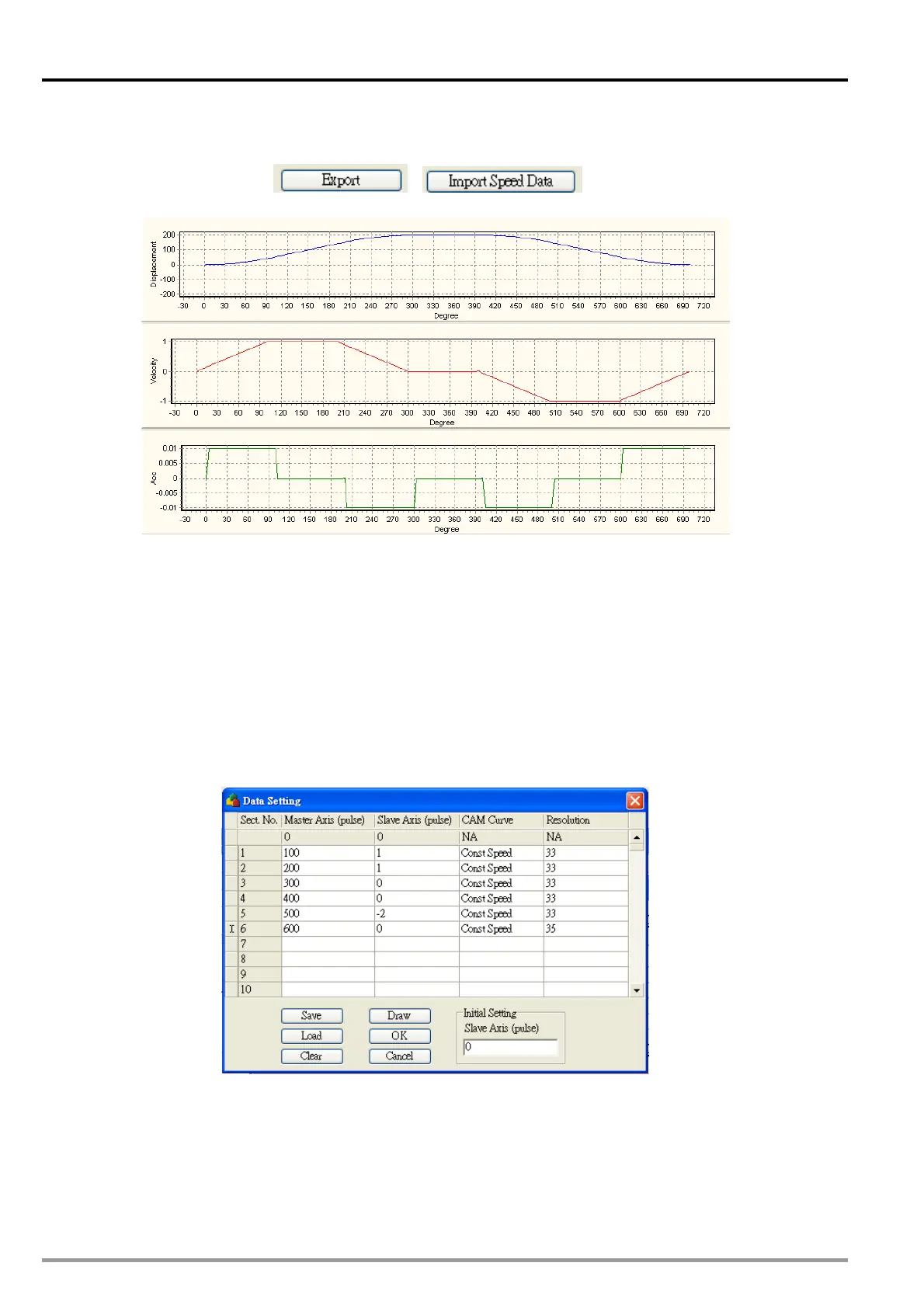

In addition, for pulses per round of Master users can apply input /output magnification setting to obtain

the proper set value. Different from the setting of rotary cut, lower/higher bound of electronic cam

synchronized output section should be specified. Also, to save the time of operation cycle users can set

a higher speed for the process when cutter returns to position 4 in the figure in section 9.6.3.1. See

below example.

In this example, modify the angle of position 4 in the figure in section 9.6.3.1 from 700 to 600 degrees

and set the stroke at section 5 as -2, indicating doubling the reverse running speed. In this case, 100

pulses (700-600) can be reduced at operation speed 100 kHz, i.e. approximately 1ms can be saved

from the whole operation cycle. However, please note that the square measure of positive pulses

should be the same as that of the negative pulses if the ready position (position 4) is required to match

starting position (position 1).

Positive square measure:

(1*100/2+1*(200-100)+1*(300-200)/2)=200

DVP-20PM Application Manual

9-62

Loading...

Loading...