EPSON Stylus Pro 9000

Disassembly & Assembly 100

CONNECTING THE CARRIAGE FFCS TO THE RELAY CIRCUIT

BOARD

1. Peel off the backing of the double-sided adhesive tape at two places: the

wall surface toward the right frame and the folded section near the center.

2. Make sure the FFCs are aligned and peel off the backing of the double-

sided adhesive tape on the second FFC. Attach the second FFC to the

back of the first one.

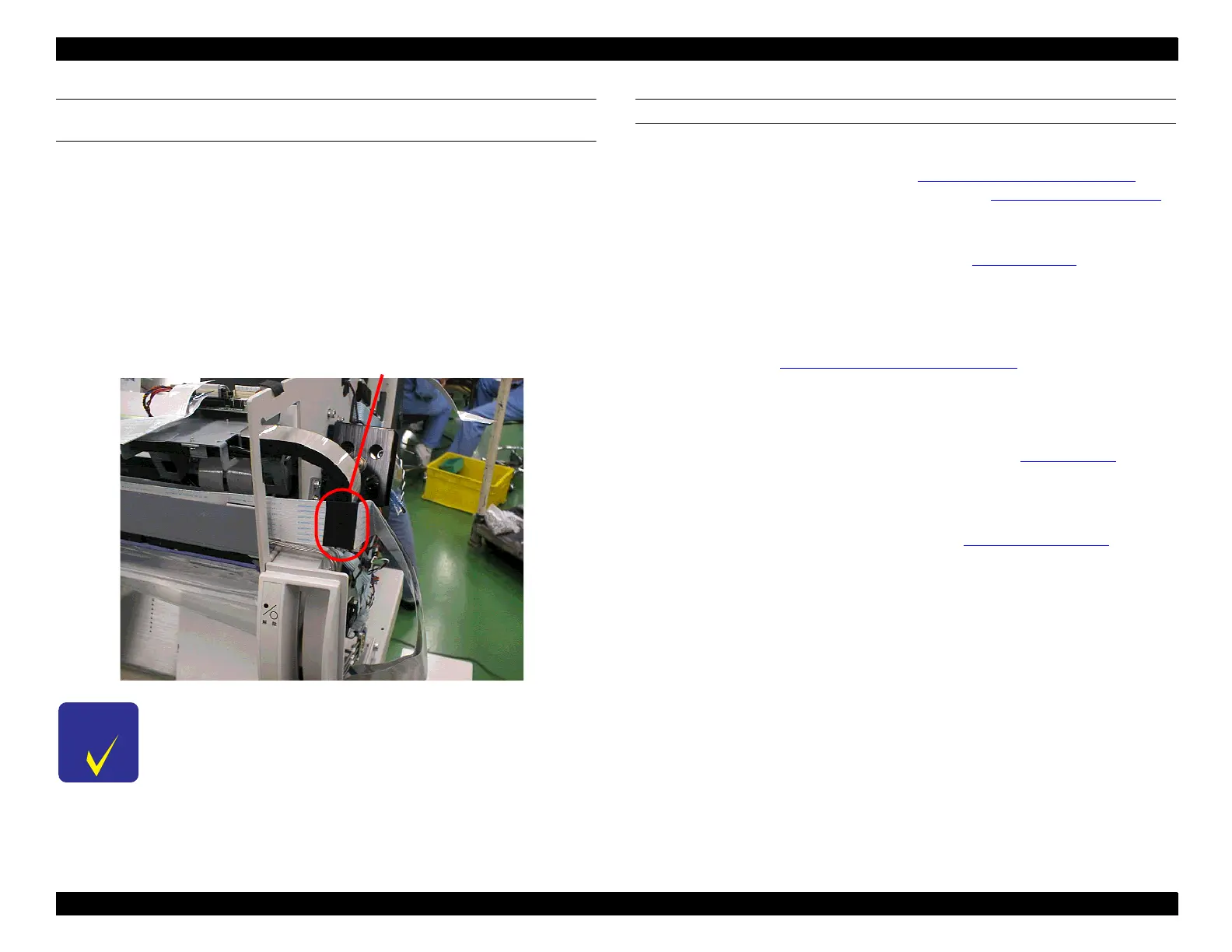

3. Fold the FFCs into three sections as shown below, and attach acetate

rayon tape.

4. Connect the FFCs to the relay board connectors.

RESETTING THE PRINTER

1. Install new ink cartridges in the printer.

2. Enter the Self-Diagnostic Mode (see Using the Self-Diagnostic Mode

on

page 108) and adjust the capping position (see Cap Position Adjustment

on page 116). After the printer automatically adjusts the cap position (a

number appears on the LCD), press the Enter button on the control panel.

3. Perform an initial ink charge (“Init. Fill” in the Cleaning menu

on page 128

of the Self-Diagnostic Mode). Check the ink discharge condition as well as

the amount of ink in the dampers. Make sure there are no bubbles, which

would indicate a leak in the ink delivery system.

4. Attach the carriage cover and perform the carriage cover height

adjustment. See Carriage Cover Height Adjustment

on page 130.

5. Lower the Paper Release Lever to prevent damage to the Paper Thickness

Sensor, and then re-attach the Top Cover, being careful not to bump the

sensor.

6. Load 44 inch roll paper and print a test pattern (see Check Nozzle

on

page 118). Check the operation of the printer, and make sure the order of

printed colors in the check nozzle pattern is B, C, M, Y, LM, LC from the

left.

7. Enter Maintenance Mode 2 as described in Maintenance Mode 2

on

page 17. Then reset the Ink Counter (“Init. Ink”) and CR Motor Counter

(“Init. CR Motor”).

CHECK

PO INT

As shown in the photo above, make sure the FFC does not

block the tube guide assembly from moving all the way to

the right.

Acetate rayon tape

Loading...

Loading...