EPSON Stylus Pro 9000

Maintenance 138

6.1 Overview

When servicing the printer, you need to perform certain routine inspection and

maintenance procedures:

Examine the parts listed in Physical Inspection and Cleaning on

page 138 and perform any maintenance as needed.

Check the printer’s maintenance counters as described in Checking

and Clearing Counters on page 139. If a part is at or near the end of

its life, replace it as instructed and clear the corresponding counter.

If the printer displays a Service Call or Maintenance Call error, a part may need

to be replaced; see

Service Error Codes and Replaceable Parts

on

page 143.

If an Ink Out light is flashing or on, see

Ink Cartridge Replacement

on

page 144.

If you notice that the paper doesn’t cut cleanly, the cutter blade may need to be

replaced. See

Cutter Blade Replacement

on page 144.

If your printouts have jagged or missing lines or gaps, see

Print Quality

Troubleshooting

on page 49. This tells you how to:

print a nozzle check pattern

clean the printhead

adjust the printhead alignment

6.2 Physical Inspection and Cleaning

When servicing the printer, inpect the following parts and perform any

maintenance as needed:

CAUTION

This printer does not require any lubrication. Refrain

from applying any oil or grease, since it may damage

the printer.

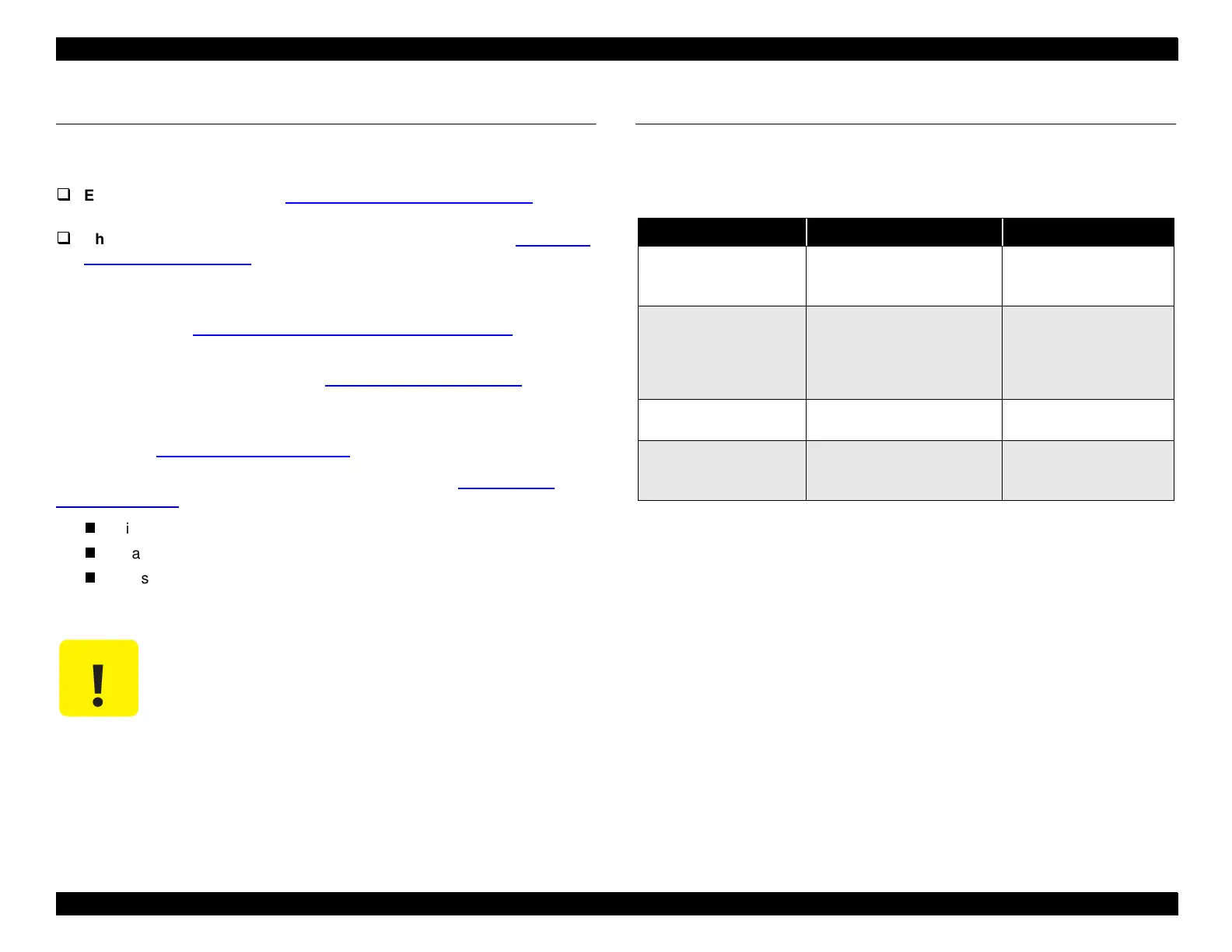

Table 6-1. Parts to be Checked During Service

Where to look What to look for Maintenance

Lower Paper Guide and

the surface of the

Subplaten

Paper shreds, paper dust,

foreign objects, or ink stains

Clean with a moist cloth,

if necessary, and then

wipe dry

Timing Fence (timing

strip used by linear

encoder to determine CR

position)

Dust, stains, or foreign

objects that may interfere

with the sensor; also make

sure the timing fence is not

bent or torn

Clean with a moist cloth,

if possible; otherwise

replace

CR Guide Rail Paper shreds or other foreign

matter

Remove any foreign

matter

Front and Rear Paper

Sensors

Paper shreds, paper dust, or

other debris on the sensor

surface

Clean using compressed

air

Loading...

Loading...