son

TE

RIII1lNAT

ION

a-lANNEL

INPUT

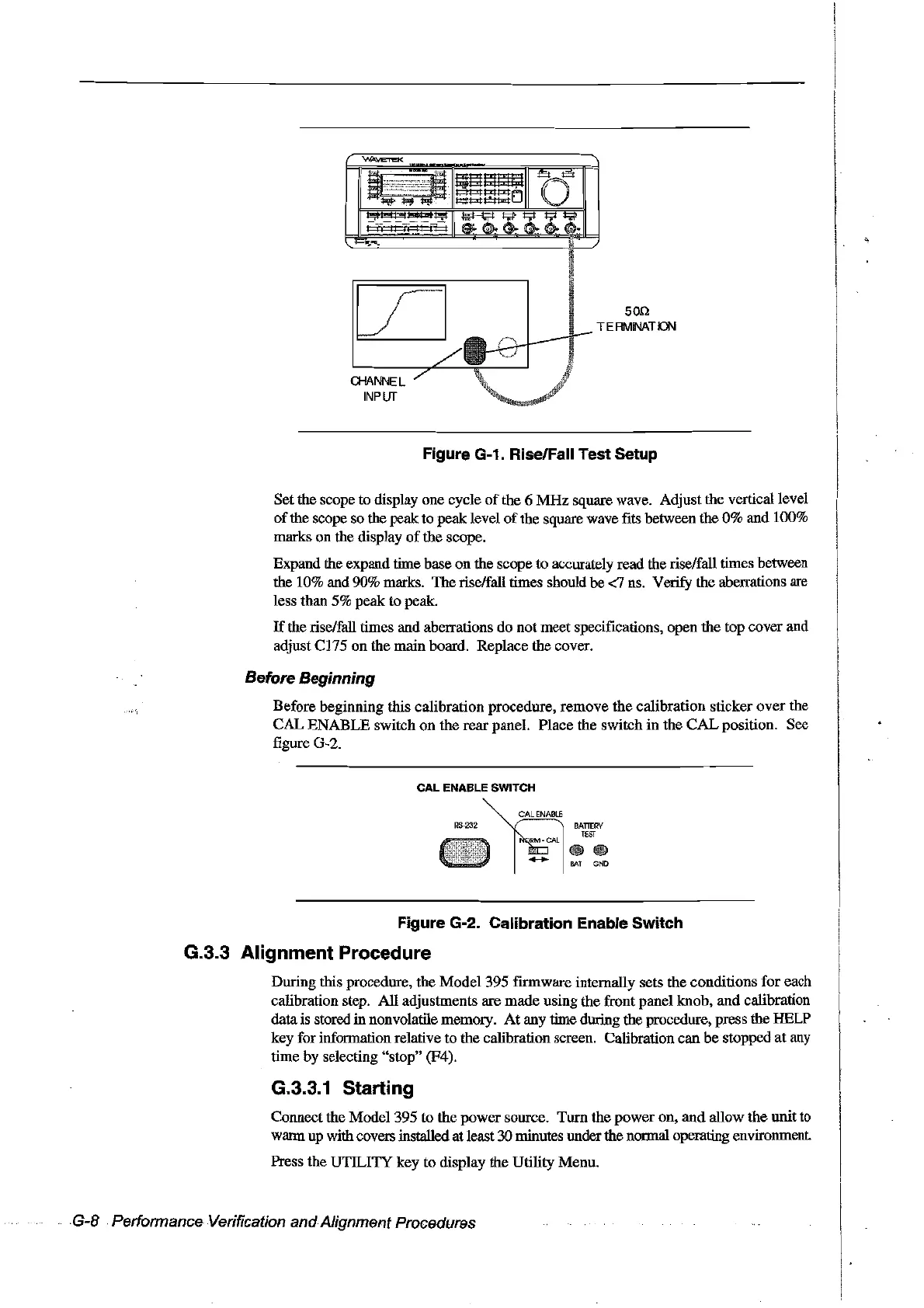

Figure G-1. Rise/Fall Test Setup

Setthe scope to display one cycle

of

the 6

MHz

square wave. Adjust the verticaIlevel

of

the scope so the

peak:

to peak level

of

the square wave fits between the

0%

and 100%

marks on the display

of

the scope.

Expand the expand time base on the scope to accurately read the rise/fall times between

the 10% and 90% marks. The rise/faIl times should

be

<7 ns.

Veri.fY

the aberrations are

less than 5% peak to peak.

If

the rise/faU times and aberrations

do

not meet specifications, open the top cover and

adjust C175 on the main board. Replace

the

coyer.

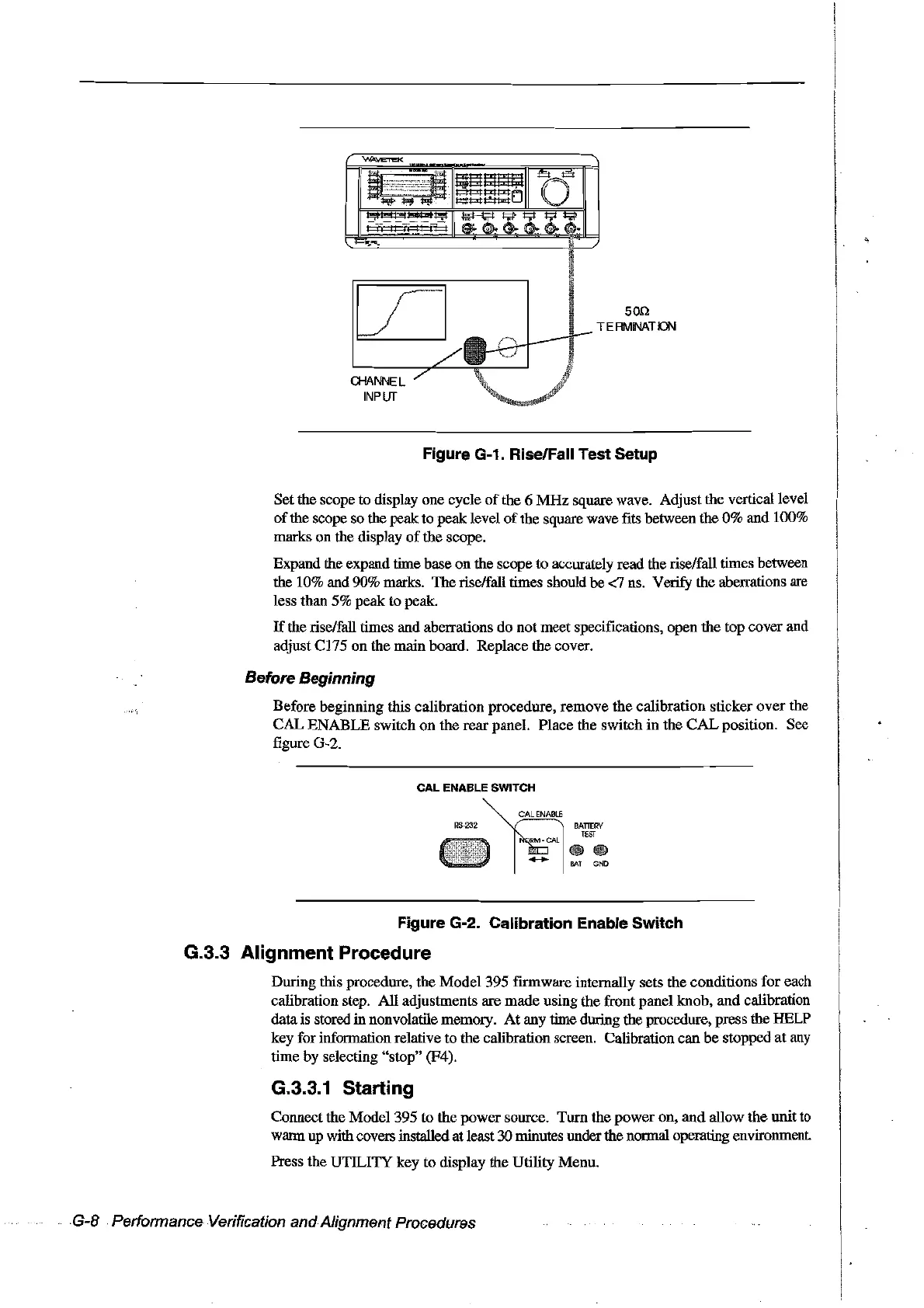

Before Beginning

Before beginning fuis calibration procedure, remove the calibration sticker

over

the

CAL

ENABLE switch on the

rear

panel. Place the switch in the

CAL

position. See

figure G-2.

Figure G-2. Calibration Enable Switch

G.3.3 Alignment Procedure

During this procedure, the Model 395 frrmware internally sets the conditions for each

calibration step. AlI adjustments are made using the front panel knob,

and

calibration

datais stored

in nonvolatile memory.

At

any time during the procedure, press the HELP

key for information relative to the calibration screen. Calibration can

be

stopped

at

any

time by selecting "stop" (F4).

G.3.3.1 Starting

Connect the Model 395

ta

the power source. Torn the

power

on,

and

allow

the

unit

to

warm up withcovers installedat least 30minutes underthe normal opemting environment.

Press the

UTILI1Y

key to display the Utility Menu.

G-8 Performance Verification andAlignment Procedures

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...