9100c

7-2 M1207026

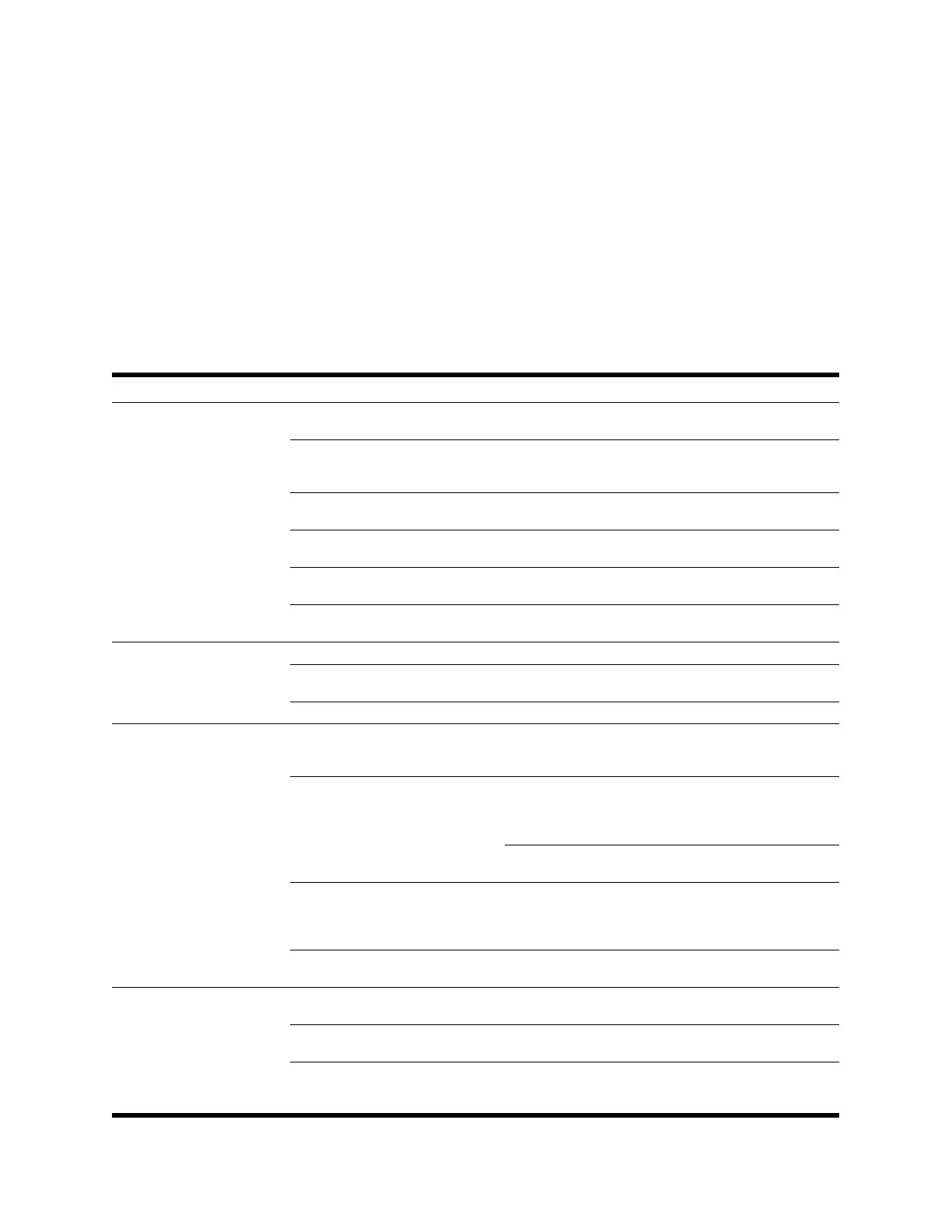

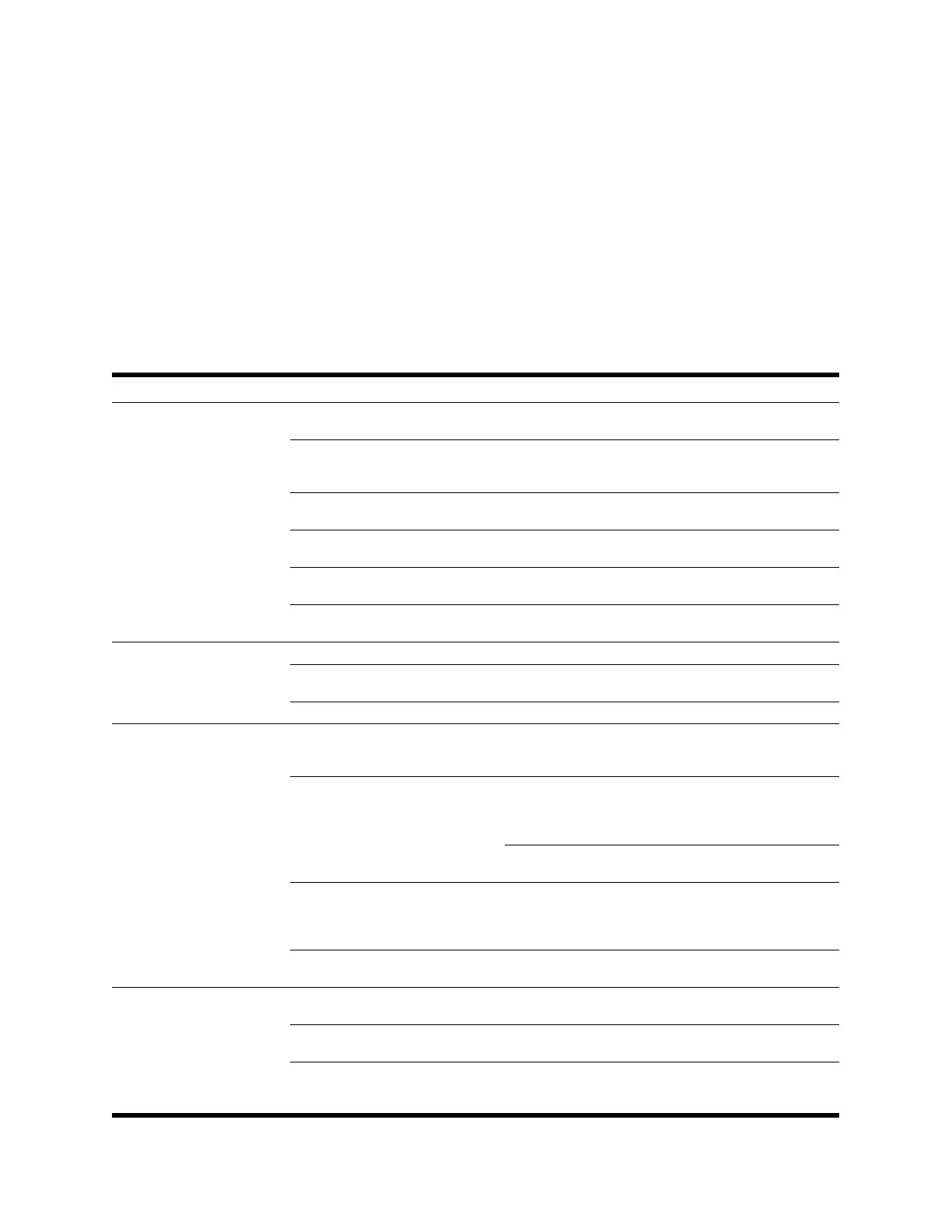

7.1 General Troubleshooting

WARNING Objects in the breathing system can stop gas flow to the

patient. This can cause injury or death:

• Do not use a test plug that is small enough to fall into

the breathing system.

• Make sure that there are no test plugs or other objects

caught in the breathing system.

Problem Possible Cause Action

High Pressure Leak Pipeline leak Use a leak detector or Snoop to check for source of leak.

Repair or replace defective parts.

O

2

flush valve Use a leak detector or Snoop to check for source of leak.

Make sure tubing connections are tight.

Replace valve if defective.

Cylinder not installed properly Make sure cylinder is correctly aligned.

Verify that T-handles are tight.

Cylinder gauges Use a leak detector or Snoop to check for source of leak.

Replace gauge if defective.

Cylinder gaskets Use a leak detector or Snoop to check for source of leak.

Replace gasket if defective.

Relief valves Use a leak detector or Snoop to check for source of leak.

Replace valve if defective.

Low Pressure Leak

(with vaporizer mounted)

Vaporizer not installed properly Reseat vaporizer if not installed properly.

Missing or damaged o-ring on

vaporizer manifold

Check condition of o-ring.

Replace if missing or damaged.

Loose fill port Check fill port. Tighten if loose.

Low Pressure Leak

(with or without vaporizer)

Leaking port valve on vaporizer

manifold

Use the Vaporizer Manifold Valve Tester to check for leak.

See Section 9.10 for instructions.

If test fails, tighten, repair, or replace as needed.

Leak at flowmeter head If vaporizer manifold passed previous tests:

Remove tubing from input side of head and occlude the

ports.

Perform leak test. If test fails, replace flowmeter assembly.

Note: An alternate method is to pressurize the system and

use a leak detector or Snoop to check for source of leak.

Leaking relief valve on vaporizer

manifold

Remove relief valve.

Occlude opening.

Perform leak test.

If test passes, replace valve.

Leaking flush valve Attach pressure measuring device on common gas outlet.

Replace valve if device shows increased pressure.

Bellows leak Pop-off valve diaphragm not sealing

properly

Disassemble pop-off valve; inspect and clean seats; reseat;

reassemble.

Bellows mounting rim loose Remove rim and pop-off valve diaphragm; reseat

diaphragm; snap rim into place.

Bellows improperly mounted or has a

hole or tear

Check that only the last bellows convolution is mounted to

the rim and that the ring roll is in the groove under the rim.

Inspect the bellows for damage; replace.

M1207027 004 MANUAL−DOC, Technical Reference Manual, Technical Reference Manual for 9100c, English−default

Reproduced from the electronic master in MATRIX

Loading...

Loading...