HT2800T_en_c.doc Page 229 of 275

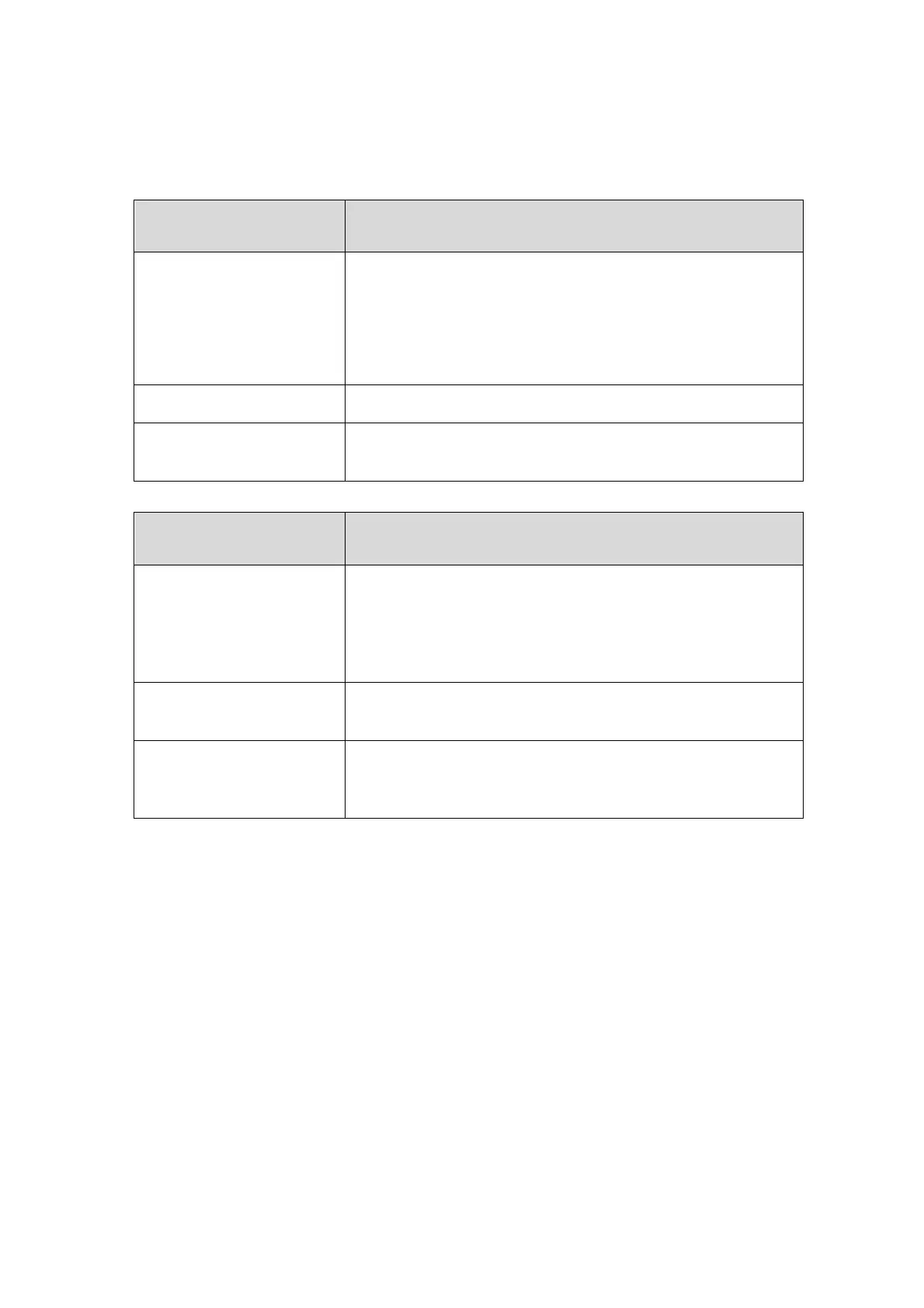

8.19.2.2 Contamination or ghost peak issue

Possible causes

Solutions

Vial cap septum dissolution in

solvent (small fragments of

septum were dissolved in the

sample).

Inject several blanks to check for ghost peaks persistence or elimination.

Check that: the syringe needle hasn't burrs that can cause septum

cutting ; septum resistance to the solvent in use; the septum is flat (see

paragraph 3.7.2).

Contamination in sample vials Try to use new or clean vials. Store new vials in a contaminant-free place

Sample instability Check the stability of the samples,and ensure they are not sensitive to

light or heat. Ensure they are stored correctly.

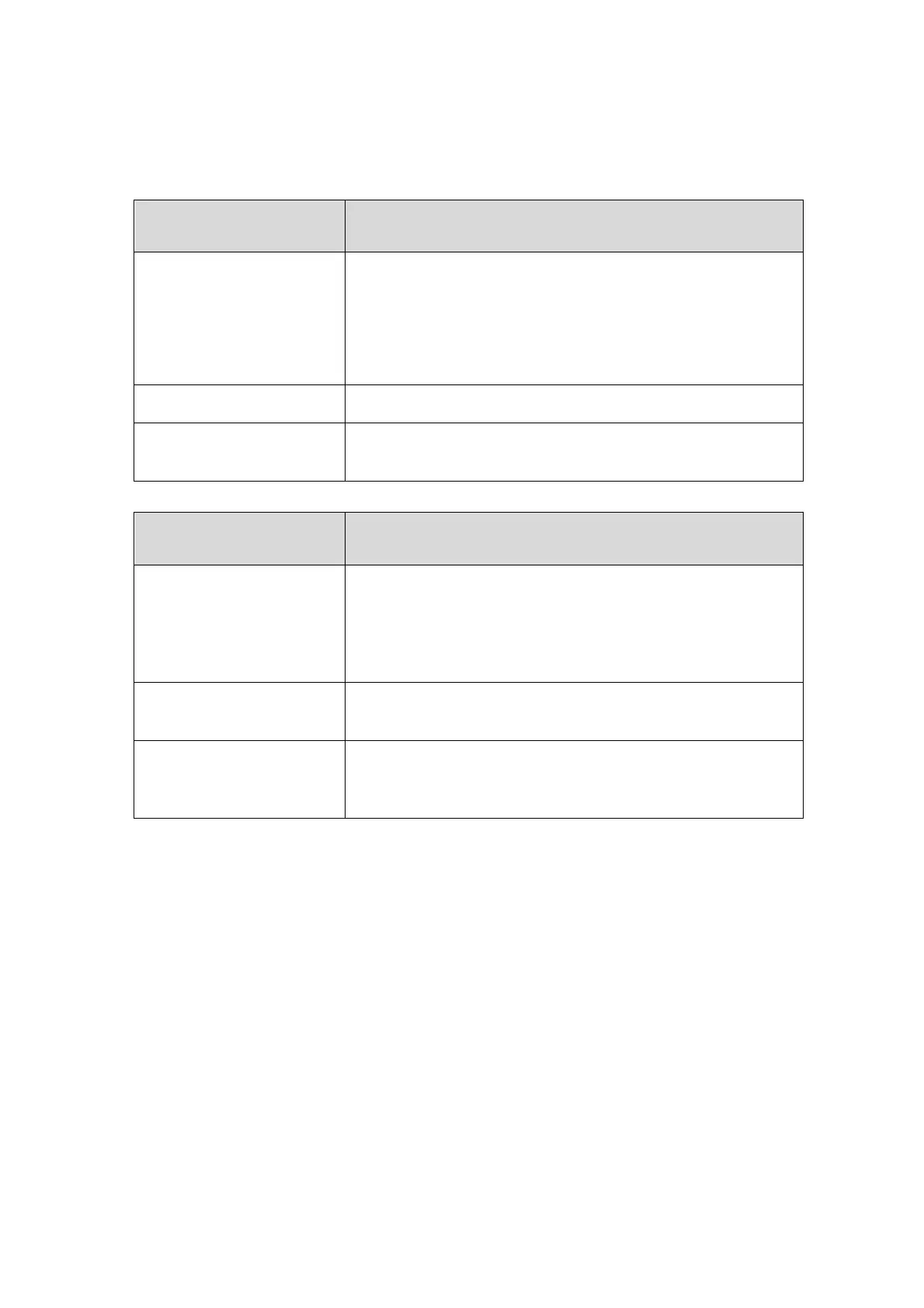

8.19.2.3 Peak size issue

Possible causes

Solutions

Leak in the GC system

Replace the septum and check the fitting to verify leak presence. If the

septum had experienced less than 100 injections, check the following

elements to avoid premature septum problems: the syringe needle is not

straight; the septum retainer nut is too tight; the syringe has not been

installed in the correct way.

Sample instability Check the stability of the samples, and ensure they are not sensitive to

light or heat. Ensure they are stored correctly.

The vials are not closed

properly

Check the caps of the vials. Loose caps may cause volatile solvents to

evaporate and change the sample concentration over time (see

paragraph 3.7.2).

Loading...

Loading...