HT2800T_en_c.doc Page 228 of 275

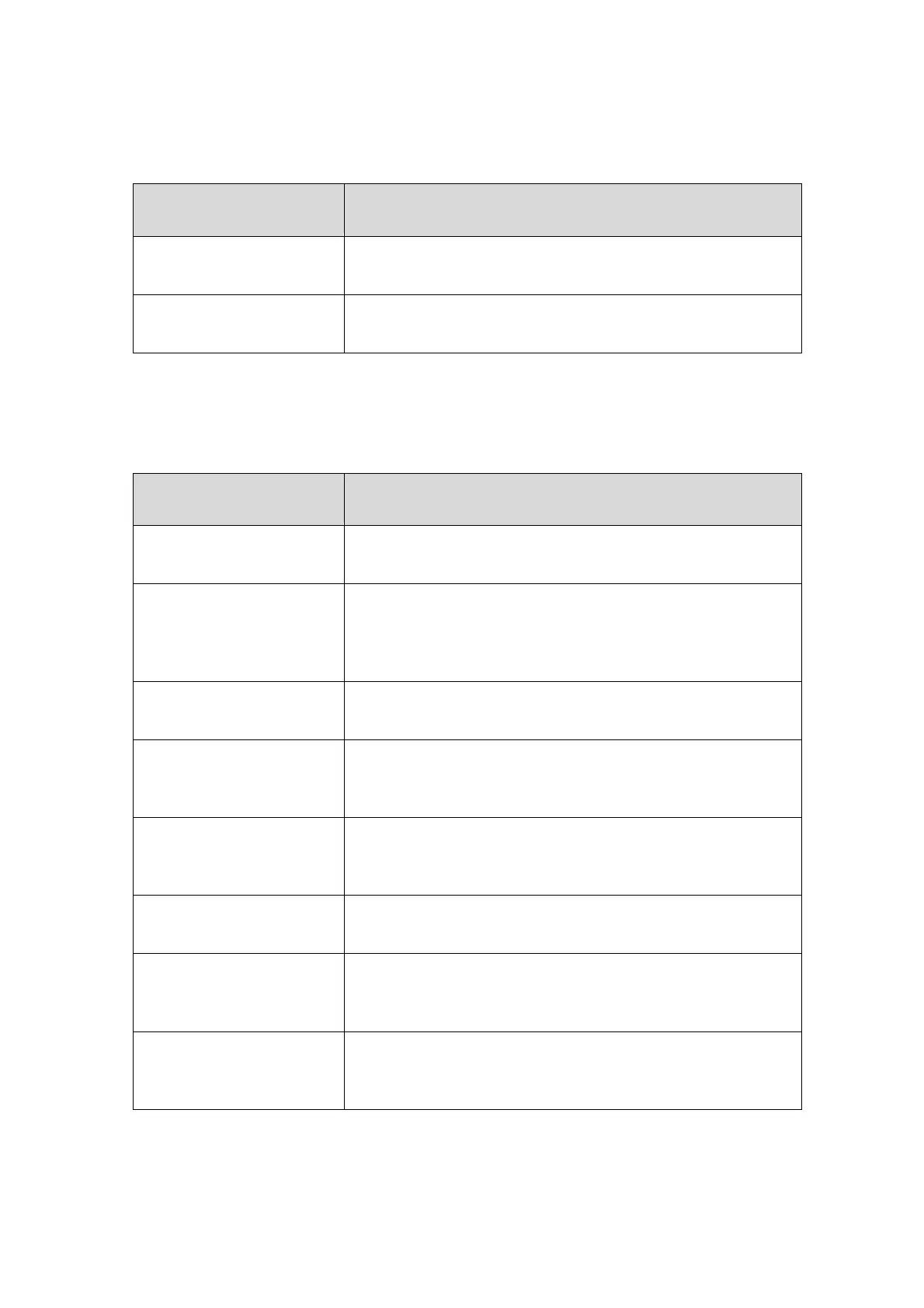

8.19.1.6 Faulty temperature read-out

Possible causes

Solutions

Probe or sensor of the syringe

holder temperature are broken

Contact your service representative.

Probe or sensor of the oven

temperature is broken

Contact your service representative.

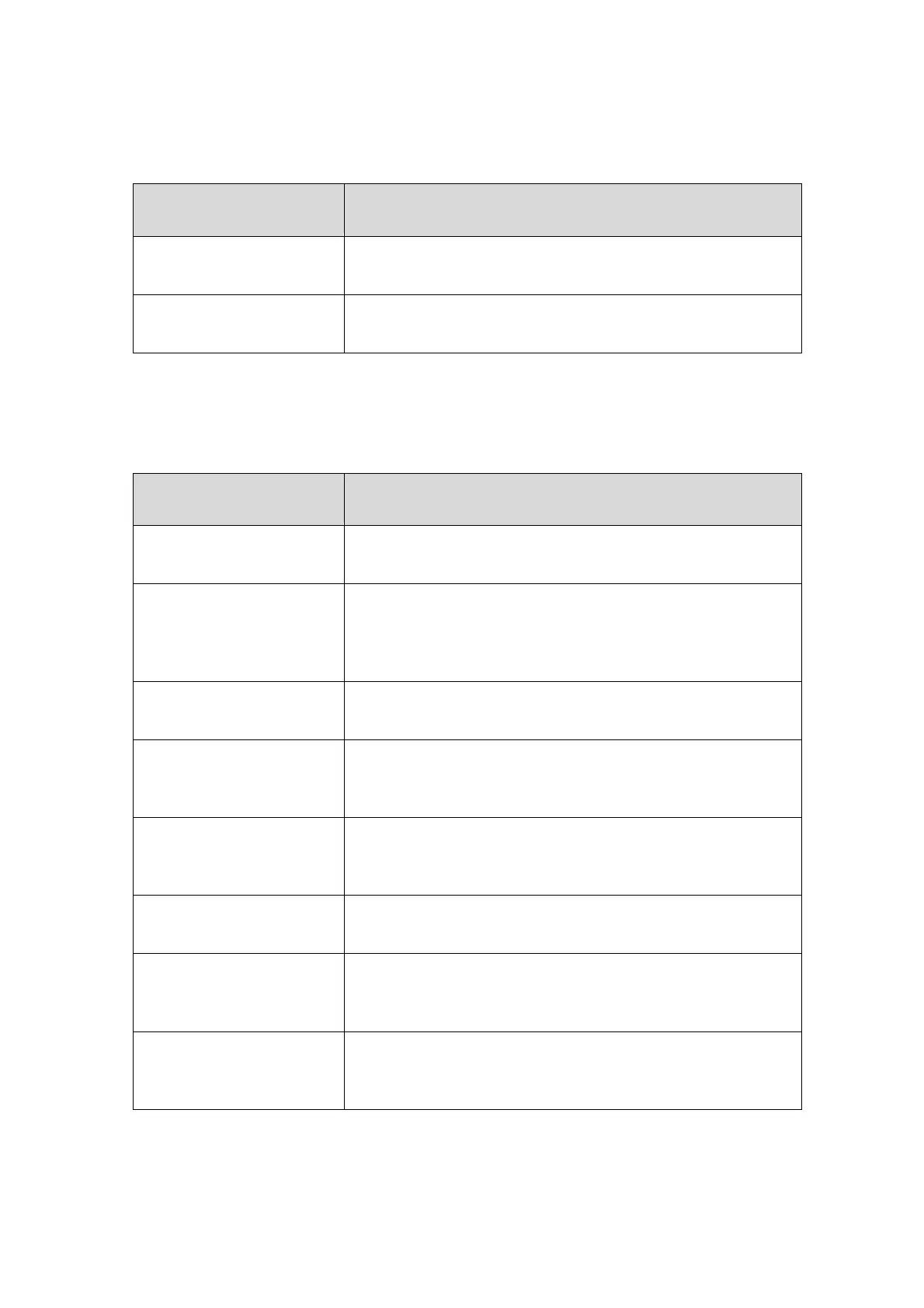

8.19.2 Analytical troubleshooting (Liquid Mode)

8.19.2.1 Reproducibility issue

Peak area or peak retention times are not reproducible.

Possible causes

Solutions

Injection Depth

Ensure the needle is set to the correct depth for the GC. This is

particularly important if the unit has just been installed or moved.

Leak in the inlet septum If there is a leak in the septum, change it. If the septum had experienced

less than 100 injections, check the following elements to avoid premature

septum problems: the syringe needle is not straight; the septum retainer

nut is too tight; the syringe has not been installed correctly.

Syringe is dirty or worn If there is dirt in the syringe or the plunger is sticking, clean the syringe

according to the manufacturer's cleaning instructions.

Sample volume in the vial is not

correct.

If the sample vial are not filled correctly, evaporation or contamination

can alter the results. The vial should only be filled up too half way (see

paragraph 3.7.1).

The vials are not closed

properly

Check the caps of the vials. Loose caps may cause volatile solvents to

evaporate and change the sample concentration over time (see

paragraph 3.7.2).

Sample instability

Check the stability of the samples,and ensure they are not sensitive to

light or heat.

Sample size variation Change the syringe (syringe is probably imprecise or worn) . For

example syringe with removable needles can cause dead volume

formation or needle to needle variation

Air bubbles inside the needle

Try to modify the following parameters: fill speed, injection speed,

viscosity delay etc... (see paragraph 5.2.2). If the samples is viscous you

can dilute it in a proper low-viscosity solvent.

Loading...

Loading...