4. Operation

4.2 Operation in Positioner Mode

4-68

ME0342-4B

[3] Pressing Operation

■ Sample use

(Position No.2 sets pressing operation.)

■ Control method

1) The method of controlling the pressing operation is the same as that described in [1]

Positioning except the setting of the position table. Any setting of “Pressing” in the position

table allows the pressing operation to be done. “Positioning width” is assumed as pressing

operation distance.

2) The actuator moves at the setting speed and rating torque to the position of the coordinate

set in “Position” in the similar way as normal positioning. The operation is executed with the

value set in “Positioning Band” for the amount of movement in the pressing operation, and

the torque (current limit) set in percent [%] in “Pressing” for the pressing operation as the

upper limit.

The actuator moves at the setting speed and rating torque to the position of the coordinate

set in “Position” in the similar way as normal positioning. The pressing is performed with the

torque (current limit value) set in percent [%] in “Pressing” of PIO pattern 4 being the upper

limit.

The pressing force when using PCON-CBP/CGBP and the maximum current limit is set

should be the maximum pressing force [N] when force sensor is used. The value for the

target pressing force [N] setting should be figured out with the formula below.

Max. Pressing Force [N]

when the force sensor is used

Target Pressing Force [N]

Max. Pressing Current Limit [%]

(Note 1)

4.2 Operation in Positioner Mode

ME0342-4B 4-69

Note 1 The maximum pressing force [N] when the force sensor is used and the maximum

pressing current limit [%] should differ depending on models. Shown in the table

below is the values for each model.

Actuator

(Pulse Pressing)

Max. Pressing Force [N]

when the force sensor is used

Max. Pressing

Current Limit [%]

RCP6-RRA7R-LCT

Caution

● It is necessary to have the calibration done on the loadcell in order to perform the force

sensor used pressing in PIO Pattern 6. Refer to [4.2.8 Preparation for Operation with

Force Sensor Used Pressing (Loadcell Calibration)]

● The force sensor used pressing is applicable only for PCON-CBP/CGBP.

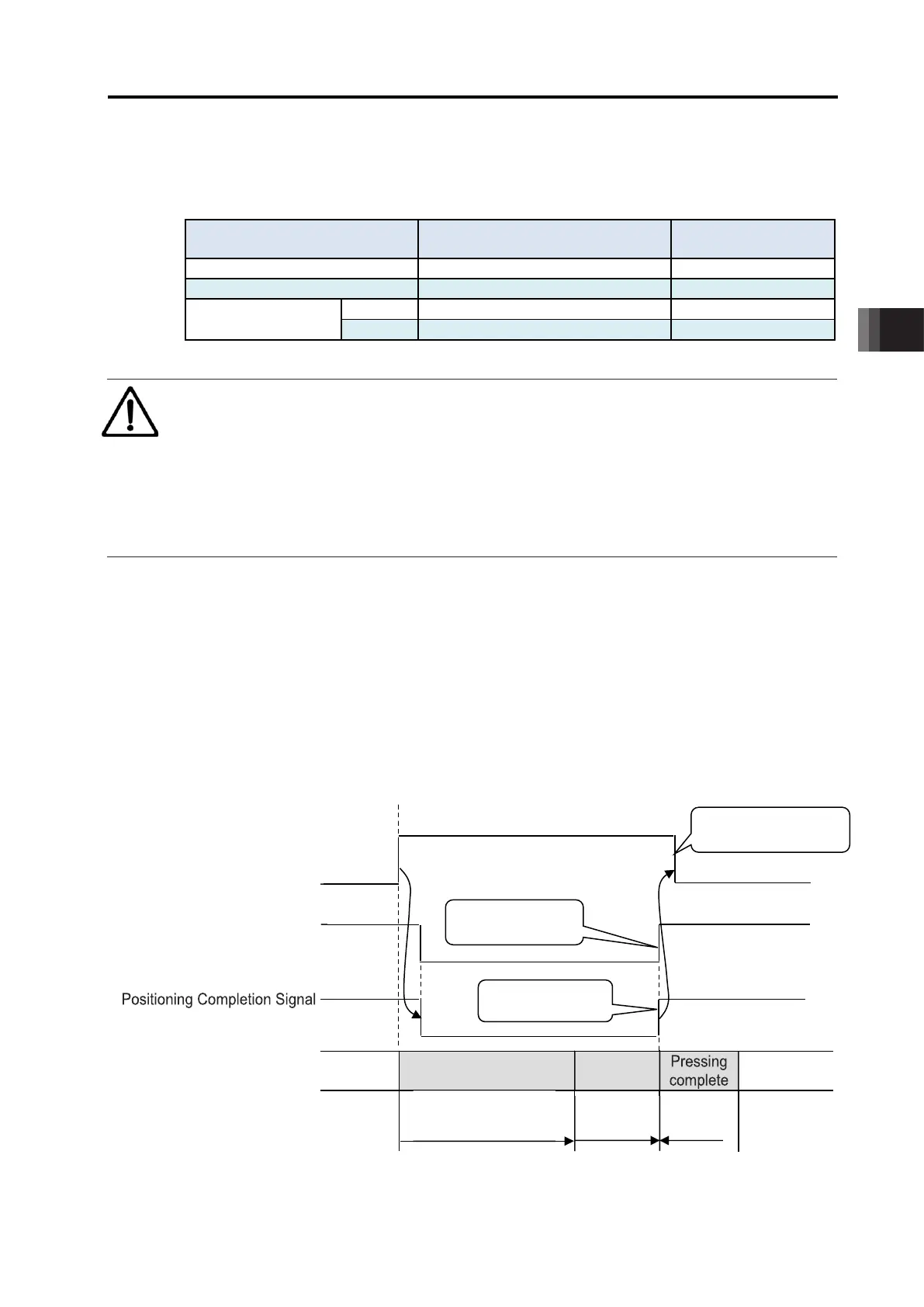

3) The control method is the same as that in [1] Positioning. However, the processing of

positioning complete signal PEND is different from that in [1] Positioning.

PEND is output when the shaft is stopped by pressing (pressing complete). If the work is not

subject to pressing (miss-pressing), the actuator moves by the value set in “Positioning

width” to stop but PEND is not turned ON. The current position No. PE* is turned ON at the

completion of pressing and even in miss-pressing.

PEND

(Controller→PLC)

Turned OFF by

turning PEND ON

Turned on even

in miss-pressing

ST*

(PLC→Controller)

PE*

→

Not turned ON

for miss-pressing

setting of coordinate

Value

positioning

width

Positioning

pressing

Loading...

Loading...