6. Parameter

6.1 Parameter

6-45

ME0342-4B

[81] Subnet Mask (Parameter No.141)

No. Name Unit Input range

Default initial value

setting

141 Subnet mask -

0.0.0.0 to

255.255.255.255

255.255.255.0

It is the parameter dedicated for Field Network (EtherNet/IP).

For details, refer to [Ether Net/IP Instruction Manual (ME0278)] provided separately.

[82] Default gateway (Parameter No.142)

No. Name Unit Input range

Default initial value

setting

142 Default gateway -

0.0.0.0 to

255.255.255.255

192.168.0.1

It is the parameter dedicated for Field Network (EtherNet/IP).

For details, refer to [Ether Net/IP Instruction Manual (ME0278)] provided separately.

6.1 Parameter

ME0342-4B 6-46

[83] Overload Load Level Ratio (Parameter No.143)

No. Name Unit Input range

Default initial value setting

143 Overload load level ratio % 50 to 100 100

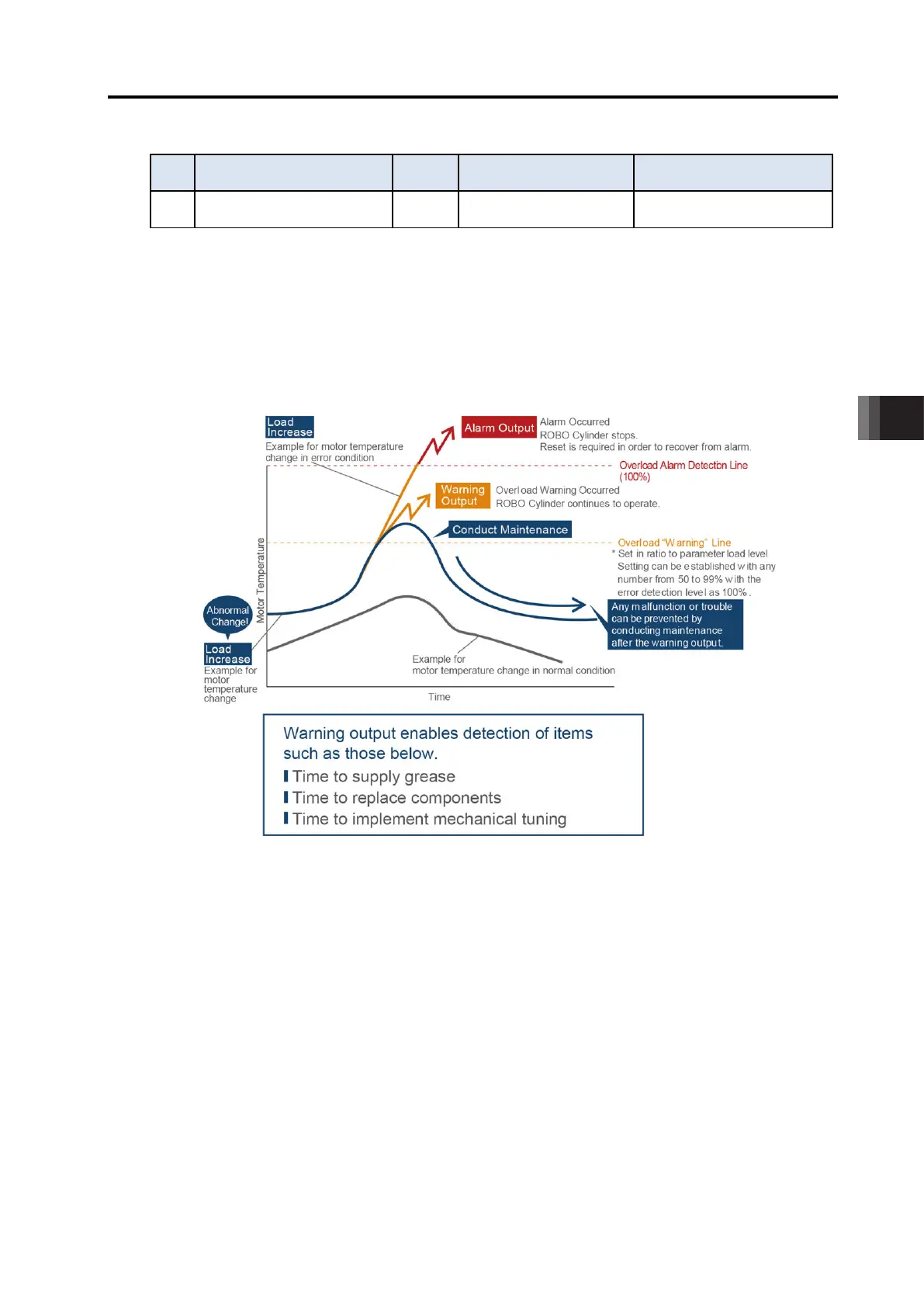

Outputs alarm 048 “overload warning” (message level) when motor temperature exceeds the ratio

set in this parameter if motor temperature under rated operation is set as 100%.

Set this parameter to 100% and the judgment should not be made.

Using this function enables monitoring of motor temperature changes caused by dried-up grease

or wear and tear on parts.

A warning is output when the preset value is exceeded.

This enables detection of abnormalities before a breakdown or a malfunction occurs.

[Applied: prevention function]

By setting this parameter, warning output notifies you before the equipment stops by error in

case that the motor temperature rises due to load condition change caused by dry-up of grease

or wear-out of components. In this alarm output, output of the PIO and each field network as the

status signal (ALML Signal) is available.

When it is required to use the overload warning, change the setting in Parameter No. 151 “Light

Malfunction Alarm Output Select” to “0”. Refer to [6.1.2 [90] Minor Trouble Alarm Output Select

(Parameter No. 151)]

Loading...

Loading...