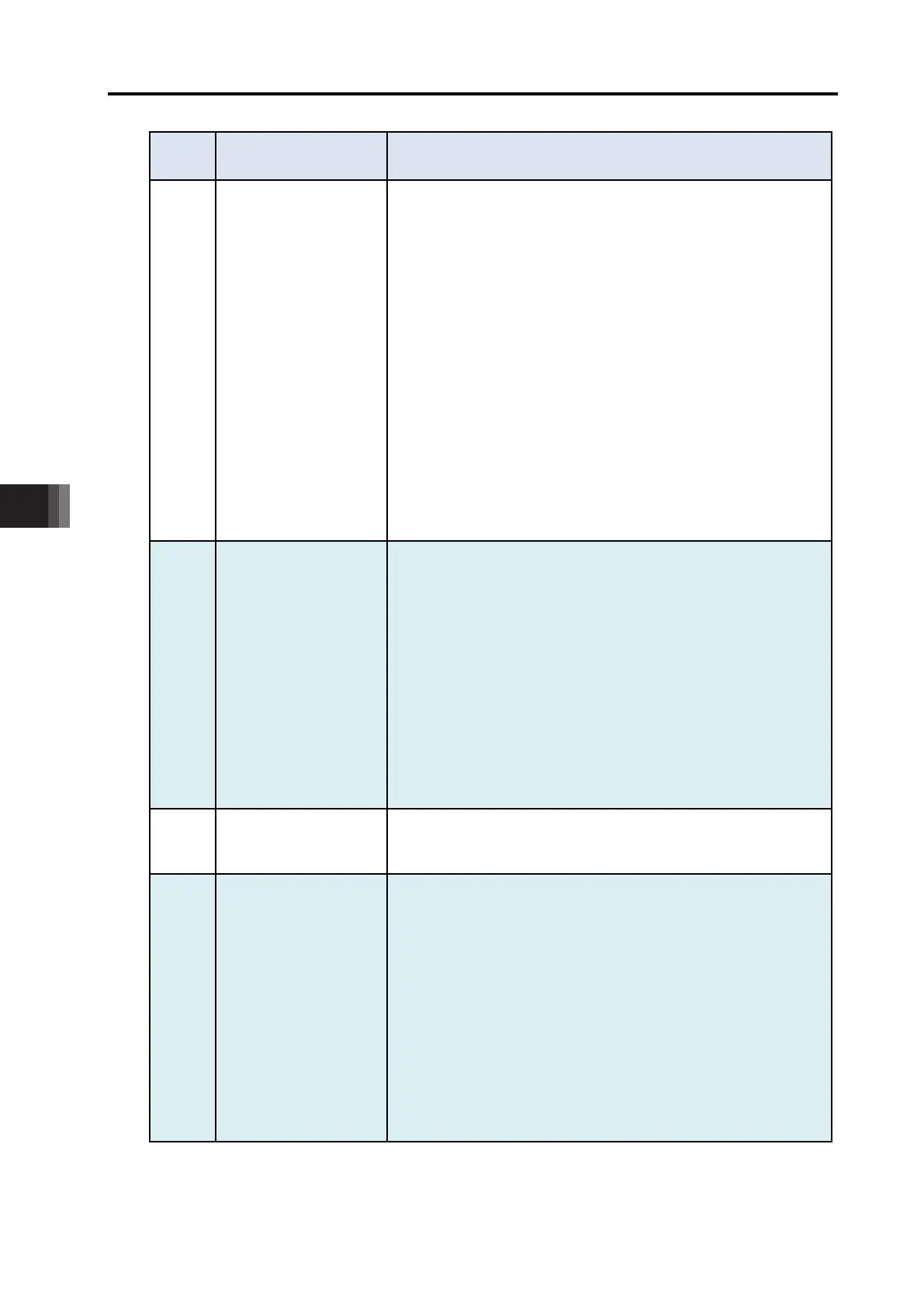

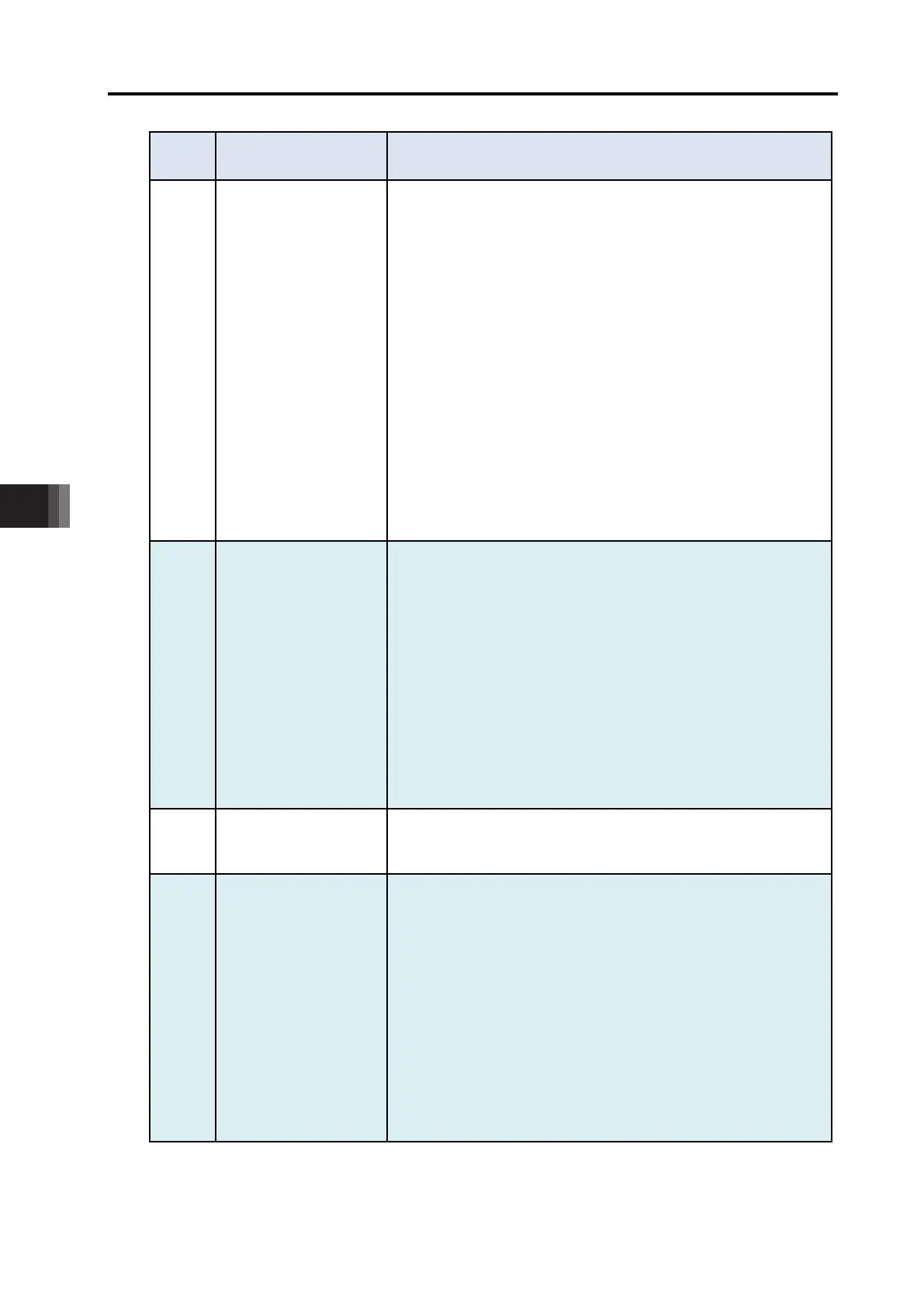

8. Troubleshooting

8.3 About Alarms

8-19 ME0342-4B

Alarm Name Alarm Name

Cause : It indicates 2s has passed without making a move since a

move command was received.

1) Connection error or wire breakage of motor/encoder

cables.

2) Brake is not released (when equipped with a brake).

3) Load to the motor is high due to external force.

4) The resistance in the actuator sliding operation is large.

Countermeasure : 1) Check for the motor/encoder cable wiring

condition.

2) Supply 24V DC 150mA to the BKRLS terminal

on the power supply connector and if you can

see an improvement, it is considered the

controller failure.

3) Confirm that there is no error in the mechanical

part assembly condition.

4) If the loaded weight is within the allowable

range, turn the power OFF and check the

resistance in sliding operation by moving the

0CE Drop in control supply

voltage

Cause : The control power voltage dropped less than the voltage drop

threshold 16.8V (70% of 24V DC).

1) The voltage of 24V DC power supply is low.

2) A faulty part inside the controller.

Countermeasure : 1) Check if 24V DC +/-10% voltage is applied to

the controller power supply input part (between

24V and 0V of the power supply connector). If

the voltage is low, the 24V DC power supply

may have failed. The current amperage

necessary for the actuator operation is not

secured. Check the necessary current

amperage in the instruction manual, and replace

the 24V DC power source.

2) Replace the controller.

Cause : Error detected on heatsink fan inside the controller.

Countermeasure :

It can be considered the end of fan life. Replace the

fan. Refer to [7.4.2 How to Replace Fan Unit]

Cause : This alarm indicates that the position deviation counter has

overflowed.

1) The speed dropped or the actuator stopped due to the

effect of external force or overload.

2) The excited-phase detection operation following the power-

on is unstable.

Countermeasure : 1) This error occurs when the actuator cannot be

operated as it is commanded. Check the load

conditions such as if the work is touching to the

surrounding object, or brake is properly

released, and remove the cause.

2) Overload can be concerned. Revise the

transportable weight and redo the home-return

Loading...

Loading...