9 Operation

9.1 Switching the machine on and off

Always switch the machine on with the «ON» key and off with the «OFF» key.

Precondition A power supply isolating device has been installed by the user.

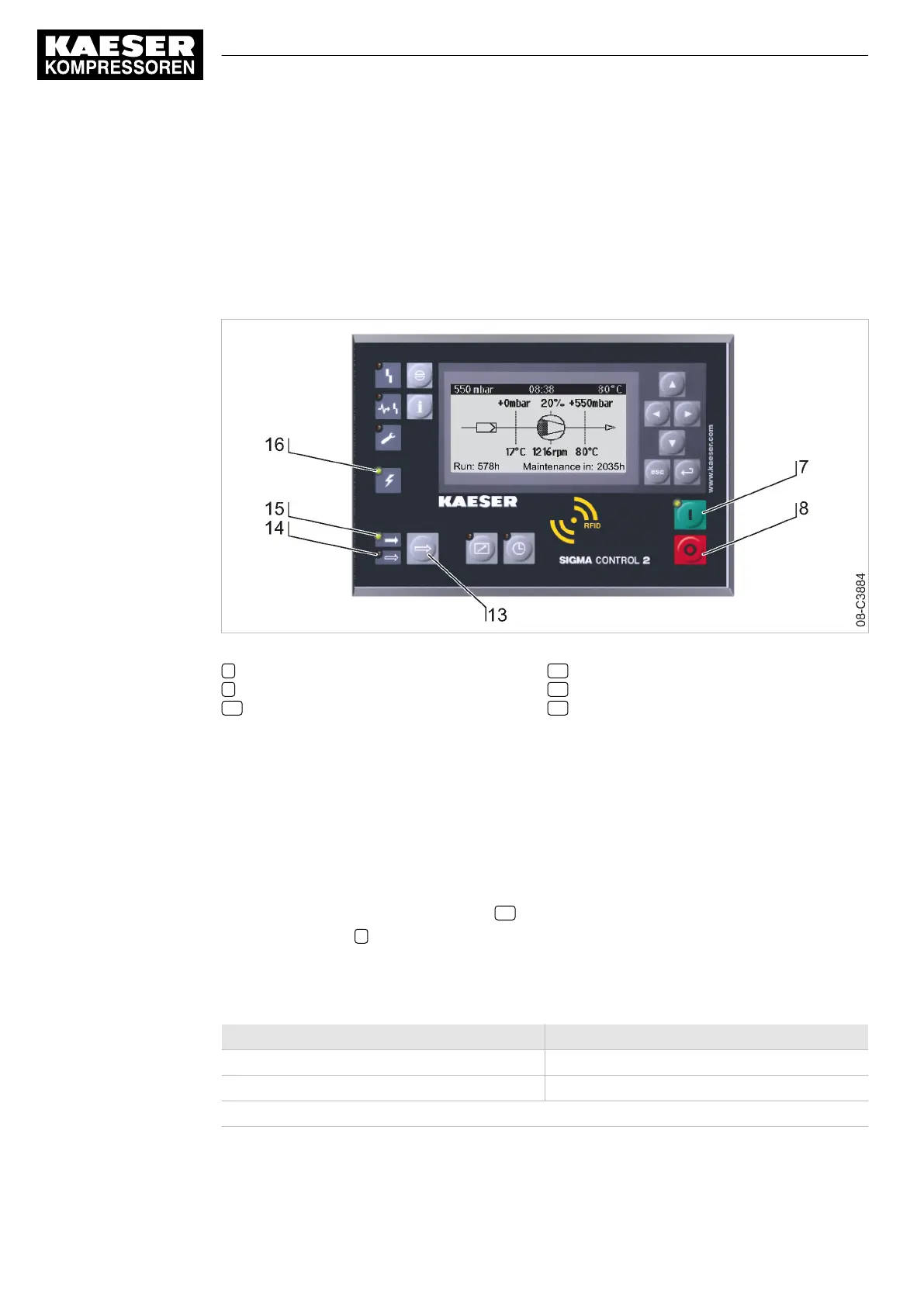

Fig. 33 Switching the compressed air station on and off

7 «ON» key

8 «OFF» key

13 «Load/Idle» toggle key

14

IDLE

LED

15

LOAD

LED

16

Voltage applied to controller

LED

9.1.1 Switching on

Precondition No personnel are working on the machine.

All maintenance doors and removable panels are in place and secured.

The ambient conditions as described in Chapter "Installation and Operating Conditions" are met

1. Switch on the user's power supply isolating device.

2. Switch on the machine and wait for SIGMA CONTROL 2 to start.

The

voltage applied to controller

LED 16 lights green.

3. Press the «On» 7 key.

The

On

LED lights green.

The minimum run time for limiting the starting frequency is active in the Remote control and Local

operating modes. The starting frequency is used only by star-delta machines.

Star period Motor starts per hour

<10 s 6

≥10 s 4

In screw blowers plus 2 minutes pause between OFF and ON

Tab. 83 Maximum permissible number of motor starts per hour

9 Operation

9.1 Switching the machine on and off

134

Service Manual Controller

SIGMA CONTROL 2 BLOWER ≥ 2.5.3 No.: 901700 10 E

Loading...

Loading...