Method Description Section

Master control via

communication module

For example, the controller (and therefore the machine) receives

the instruction LOAD or IDLE via the PROFIBUS master (e.g.

SIGMA AIR MANAGER).

8.7.3

Master control via re‐

mote contact

The machine is controlled by signals from a master controller. 8.5.4

Master control of two

machines in master/

slave operation

The two SIGMA CONTROL 2 controllers operate as master and

slave.

8.7.4

Tab. 64 Overview of the different master controllers

8.7.1.1 Priorities in master control operation

These priorities are valid in master control operation:

■ Bus (top priority)

■ External contacts (load contact)

■ Master/slave operation

■ Timer control (lowest priority)

8.7.2 SAM 4.0 mode

You must modify the settings in SIGMA CONTROL 2 for the operation via SIGMA NETWORK us‐

ing, for example, the KAESER SIGMA AIR MANAGER 4.0 (SAM 4.0).

Precondition SIGMA CONTROL 2 is connected to SAM 4.0 via SIGMA NETWORK and ready for operation (see

the SAM 4.0 operating manual in the chapter “Installation”)

Network pressure pB is set as the pressure for the “SAM 4.0 manual mode".

Access level 2 is activated.

The remote control is activated (see chapter 8.2.13)

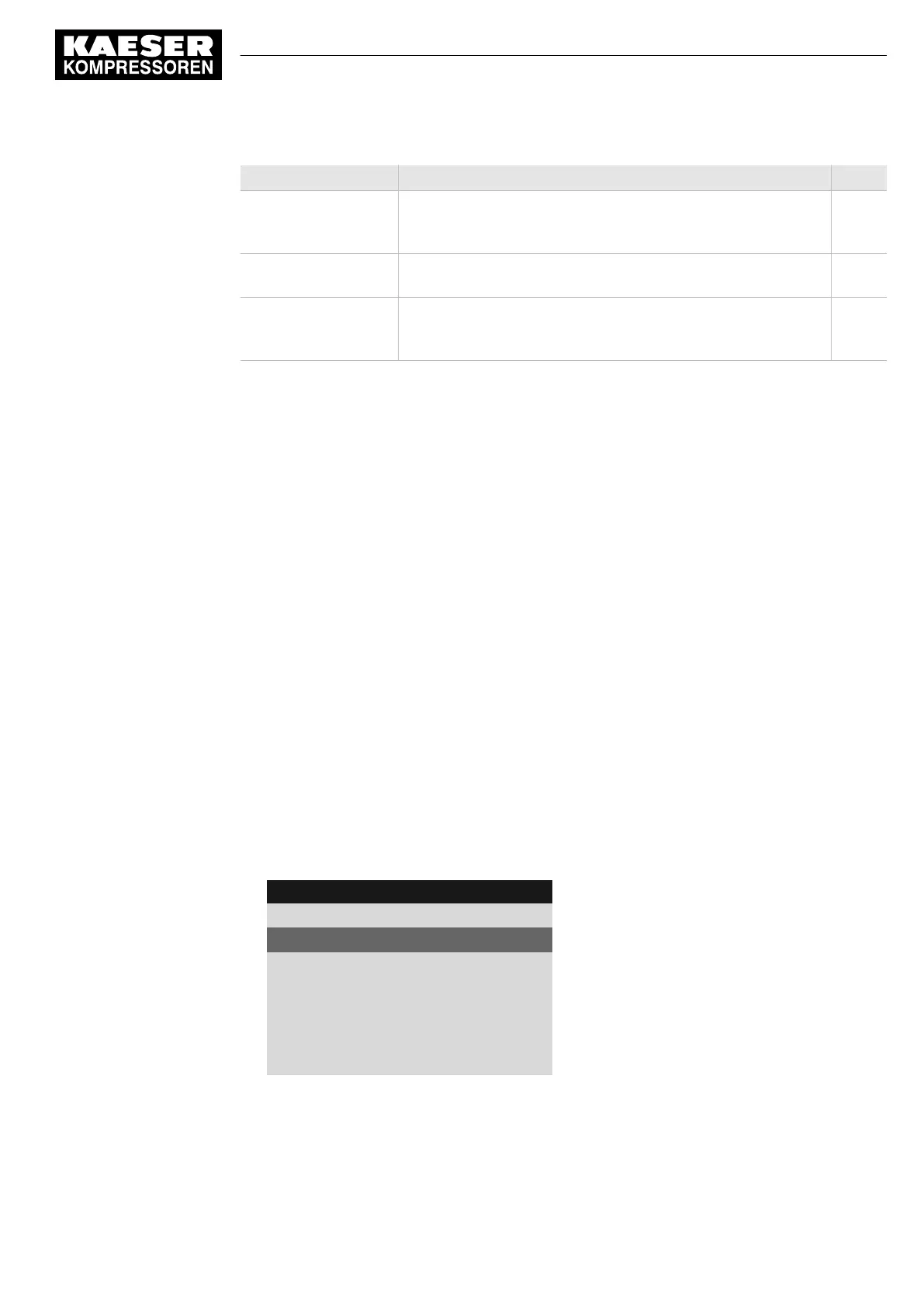

Setting the IP configuration

1. Open the 8.1.1

<Communication – Ethernet/SIGMA NETWORK – IP configuration>

menu.

2. Use «Up» or «Down» to select the

IP address

line.

4 0 0 m b a r 0 8 : 1 5 A M 8 0 ° C

Header

8.1.1 IP configuration

Menu

IP address 169.254.100.103

active line, factory setting

Subnet mask 255.255.000.000

Gateway 169,254,100.97

DNS Server 1 169,254,100.97

DNS Server 2 169,254,100.97

Restart network ☐

3. Set the IP address for SIGMA CONTROL 2 using the following pattern:

169.254.100.(SAM 4.0 machine number +102)

(for the setting see chapter 8.2.14).

8 Initial Start-up

8.7 Setting the machine for master control operation

No.: 901700 10 E

Service Manual Controller

SIGMA CONTROL 2 BLOWER ≥ 2.5.3

103

Loading...

Loading...