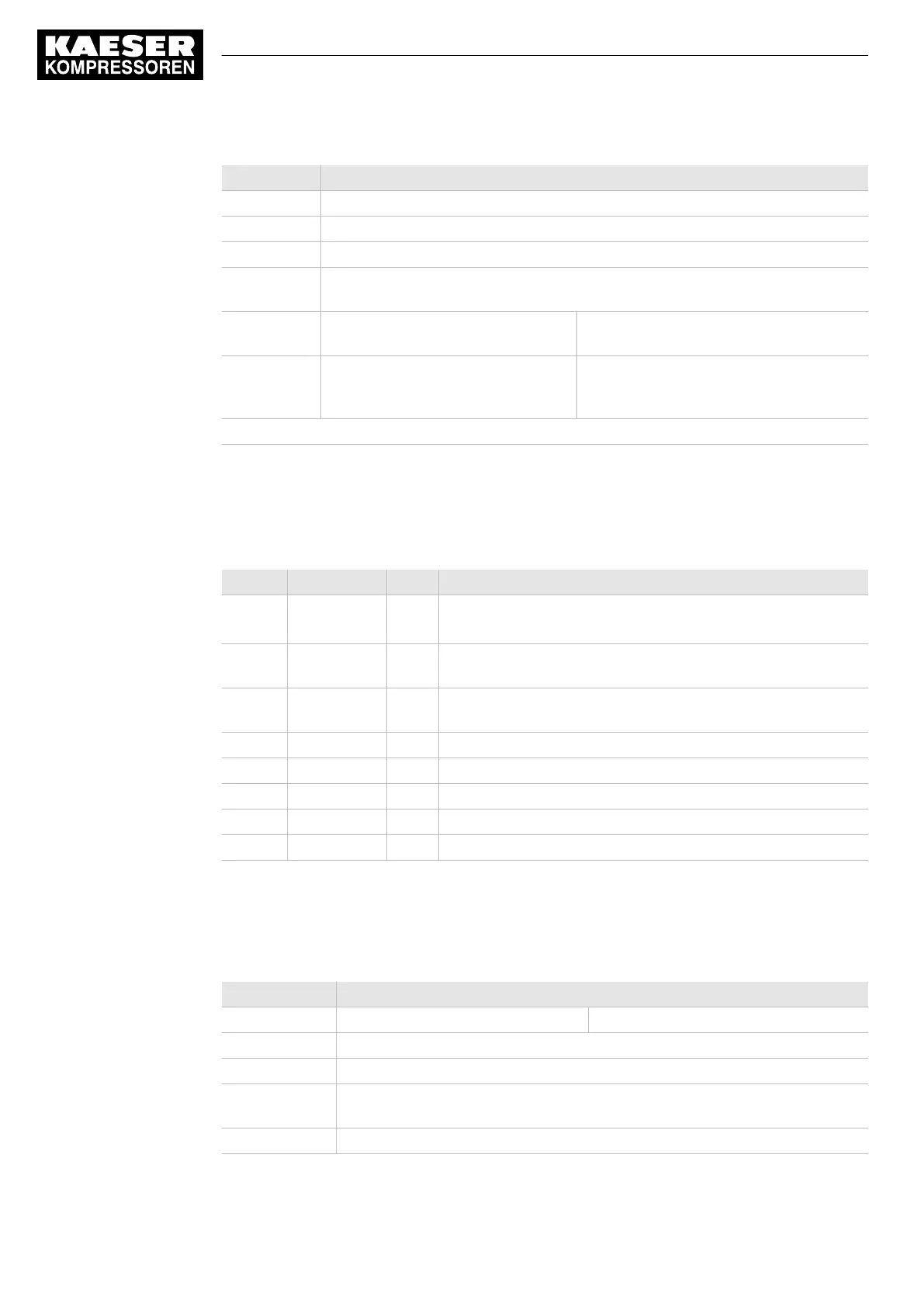

Feature Value

Time-out [ms] Possible settings 0...2000 ... 99999

Data bits: RTU: 8, ASCII: 7

Mode Possible settings RTU / ASCII

Input data

[byte]

64

Output data

[byte]

128 (process data) and 42 (diagnos‐

tic data)

128 (prozess data)

Data content "Technical description

SIGMA CONTROL 2 process image",

document number 7_7601xPA.

"Technical description

SIGMA AIR MANAGER 4.0 process im‐

age", document number 7_9696_PA.

Bold elements: Factory setting

Tab. 21 Technical Specifications - SIGMA CONTROL 2 interface

Assignment of the SIGMA CONTROL 2 interface

The Modbus interface is galvanically isolated and features RS485 and RS2232 signals. To use the

RS232 interface, connect Pin 2 with Pin 3.

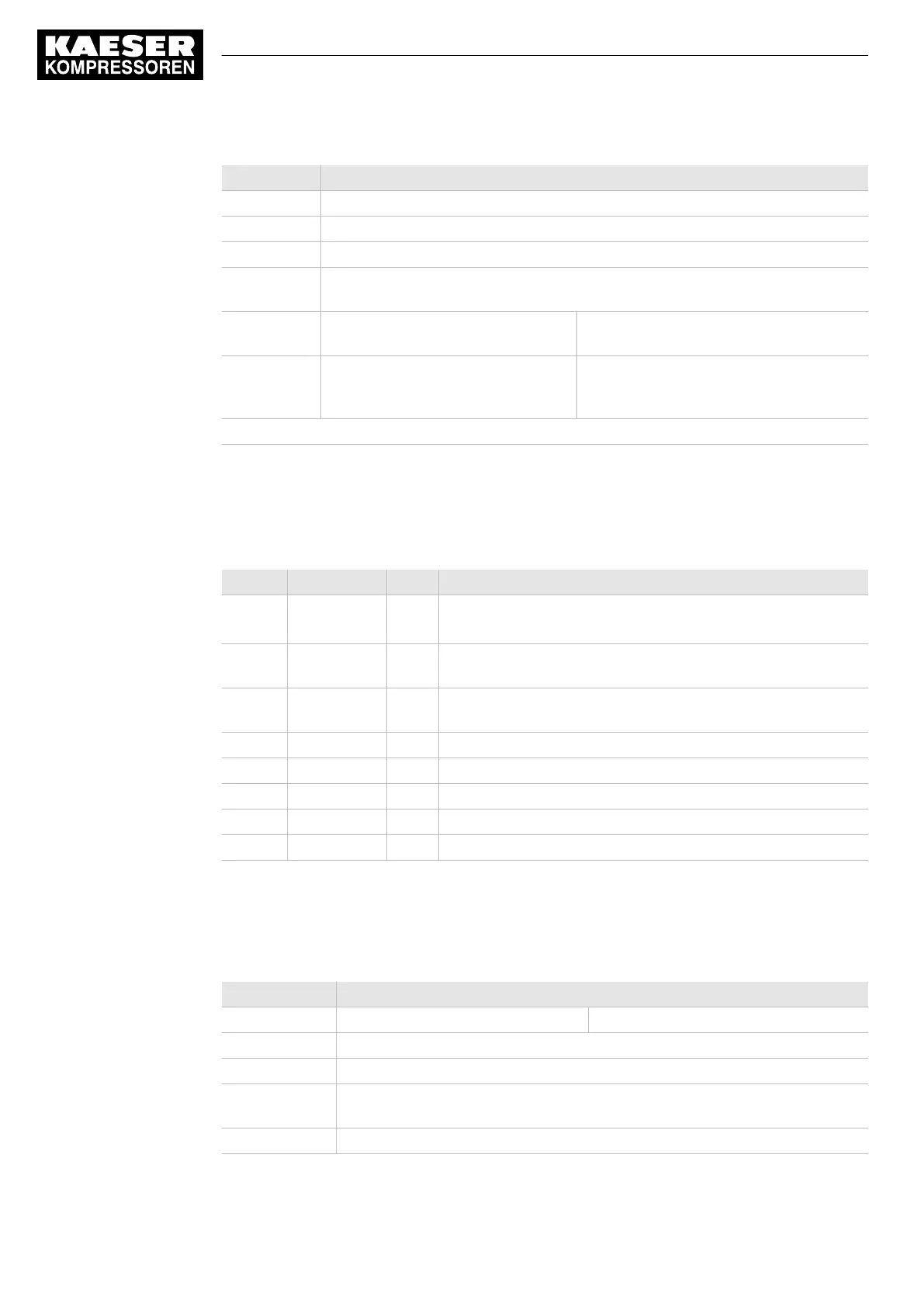

Pin Direction Signal Description

1 — GND

C/C’

Data reference potential (isolated),

RS485: Bus polarisation, for terminating resistor (pull-down)

2 Output VP +5V DC (isolated, max. 10mA) RS485: Bus polarisation,

+5V for terminating resistor (pull-up)

3 Input PMC To use RS232, connect with Pin 2.

To use RS485, keep open.

5 Bi-directional B/B’ RS485 B (RxD/TxD positive)

7 Input RxD RS232 Receive data

8 Output TxD RS232 Send data

9 Bi-directional A/A’ RS485 A (RxD/TxD negative)

Housing — — Internally connected to functional earthing (FE)

Tab. 22 Assignment of the SIGMA CONTROL 2 interface

3.2.3 Modbus TCP module

Modbus TCP-Interface

Feature Value

Controller SIGMA CONTROL 2 SIGMA AIR MANAGER 4.0

Bus Modbus TCP server (Slave)

Connection 2x RJ45 ports (Cat5e, shielded), integrated 2-port switch, potential isolation

Baud

rate [Mbit/s]

10/100, full duplex or half duplex

Input data [byte] 64

3 Technical Specifications

3.2 Communication modules

14

Service Manual Controller

SIGMA CONTROL 2 BLOWER ≥ 2.5.3 No.: 901700 10 E

Loading...

Loading...