9.7 Setting the maintenance interval

Example: Changing the lubricating oil change maintenance interval.

Precondition Access level 2 is activated.

The operating mode is displayed.

1. Open the 4

<Maintenance>

menu.

2. Use «Up» or «Down» to select the line displaying the maintenance interval to be set.

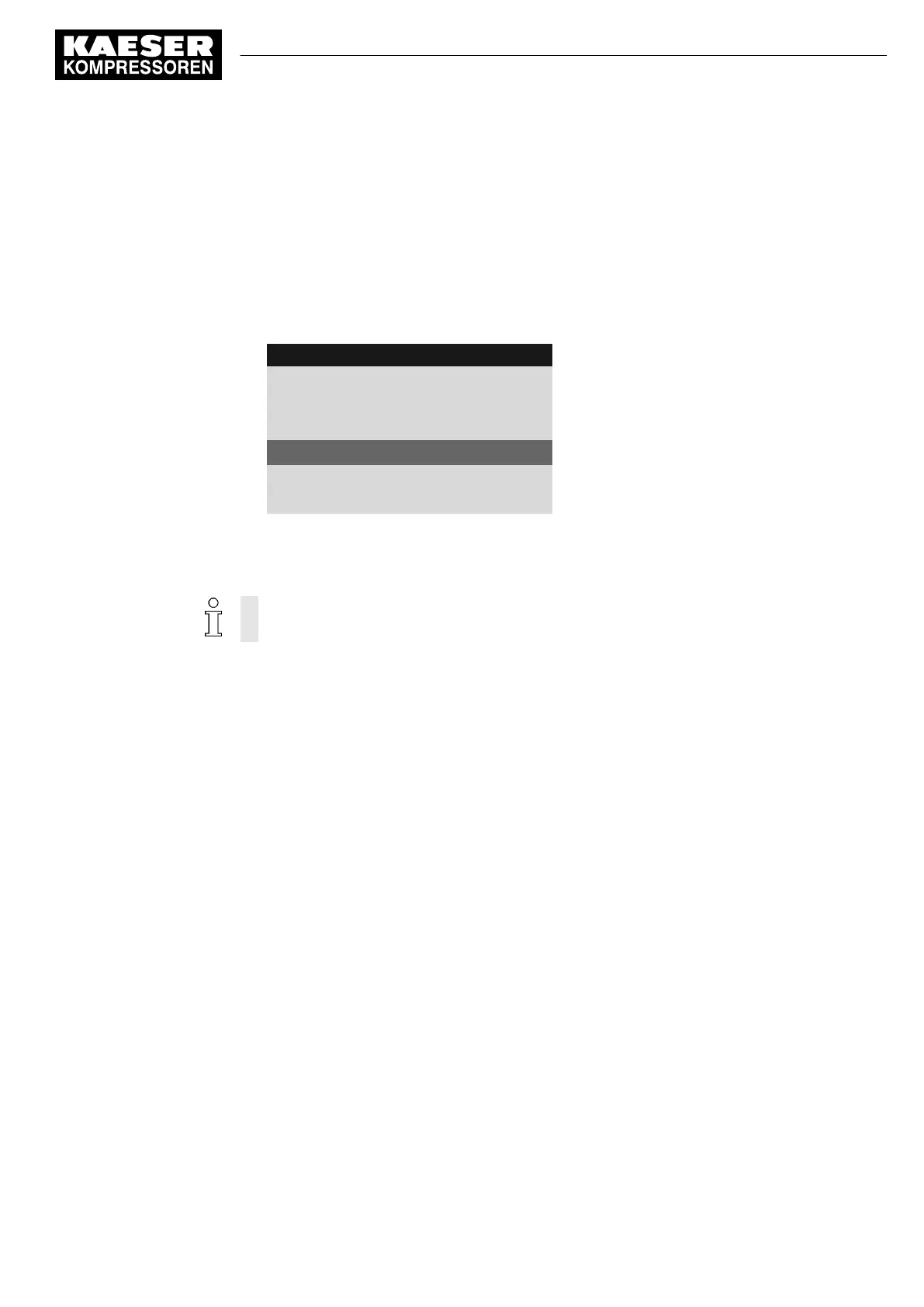

4 0 0 m b a r 0 8 : 1 5 A M 8 0 ° C

Header

4 Maintenance

▶1 Load balancing

Change block oil

Maintenance interval description

3000h ¦ 2799h Reset ☐

Active line, factory-defined interval 3000 h

······························

Change belt

3. Press «Enter».

The maintenance interval display flashes.

4. Use «Up» or «Down» to set the new value for the maintenance interval.

Keep the «Up» or «Down» key pressed to quickly change the maintenance interval in incre‐

ments of 10, 100 or 1000.

5. Press «Enter».

The setting is applied.

6. Press the «Right» arrow twice.

7. Press «Enter».

The check box will flash.

8. Press the «Up» key.

The check box is activated.

9. Press the «Enter» key.

The counter for the maintenance interval is reset.

10. Press «Escape» repeatedly to leave this menu.

9.8 Communication modules

9.8.1 Displays at the PROFIBUS module

The communication module features LEDs providing information about the module status.

9 Operation

9.7 Setting the maintenance interval

No.: 901700 10 E

Service Manual Controller

SIGMA CONTROL 2 BLOWER ≥ 2.5.3

143

Loading...

Loading...