Kinco FD5P AC series servo driver

册

Chapter7:Tuning of the servo system control

Note

The smaller the value of the K_Acc_FF parameter, the greater the position loop

acceleration feedforward.

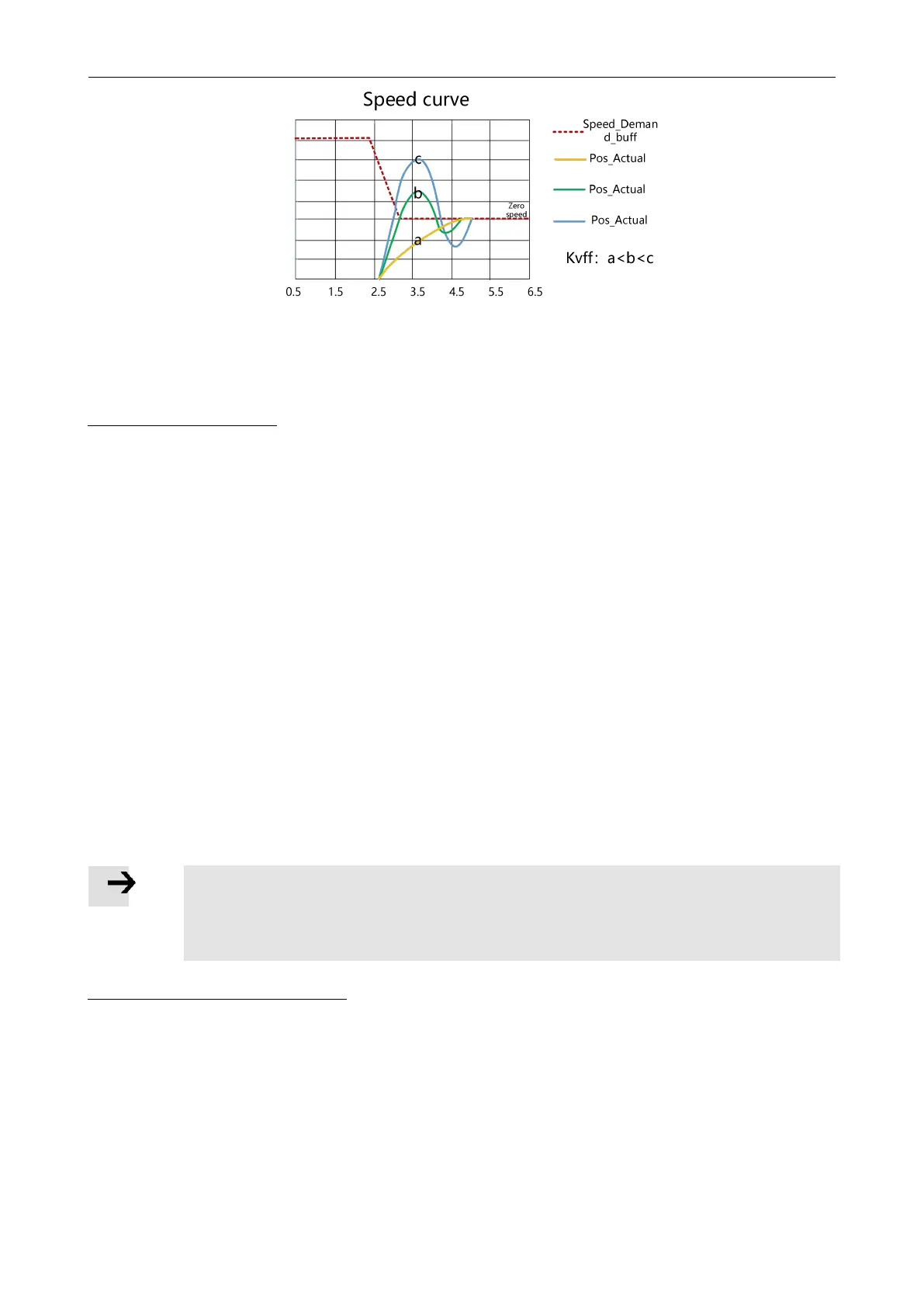

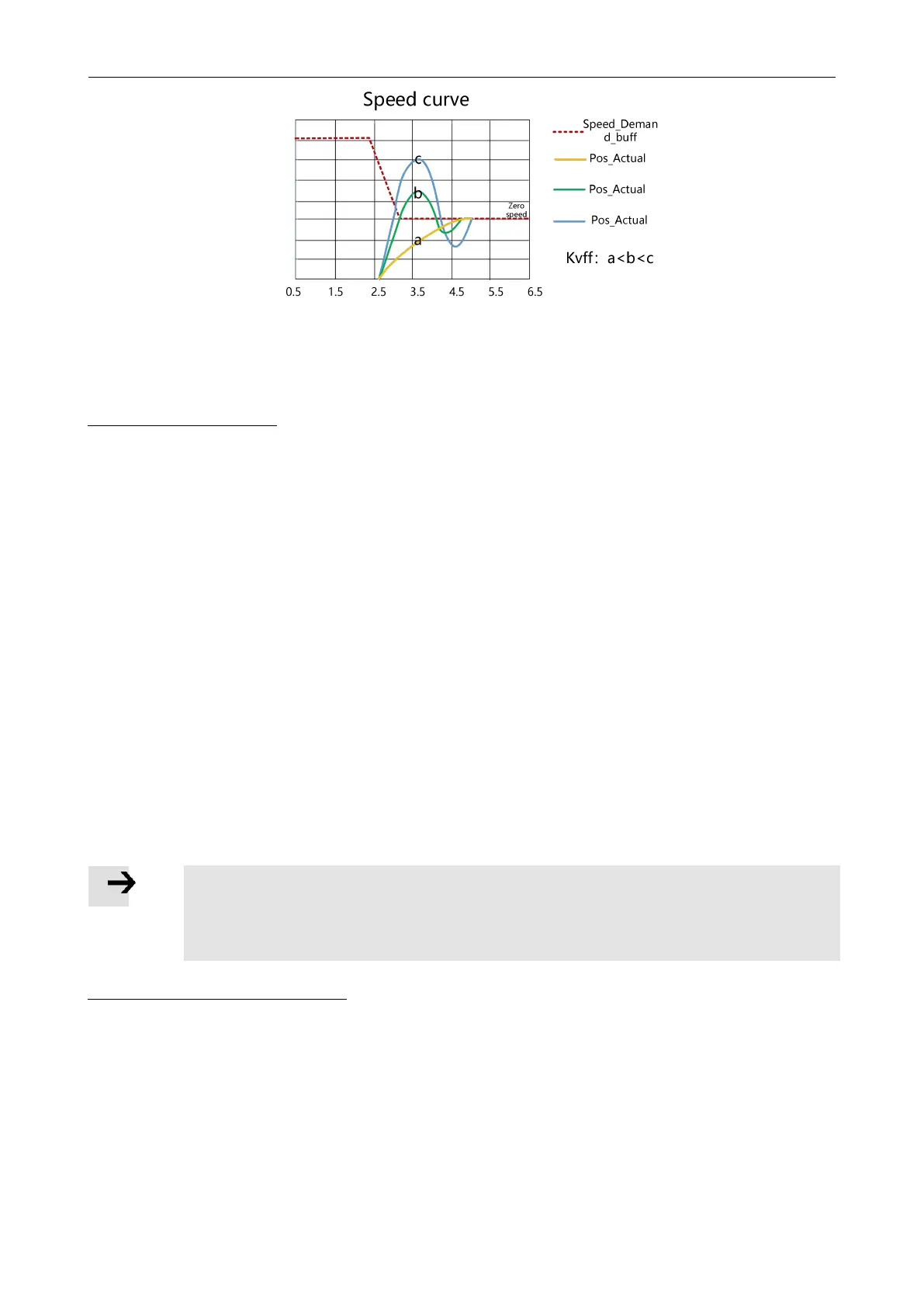

Figure 7-6 Speed step curve after Kvff adjustment

Step 3:Kaff adjustment

Users are not advised to adjust this parameter. When the practical application requires very high

position loop response, the acceleration feedforward can be adjusted to improve the response

performance.

The acceleration feedforward function can be seen as the upper controller has the opportunity to

directly control the torque in the position operating mode. This function actually consumes some of the

current loop responsiveness, so if the settings do not match the Kvp and velocity loop bandwidth,

overshoot and oscillation will occur.

Also, the velocity feed forward to the velocity loop may not be smooth and has some noise signal

inside, so a large velocity feed forward value will also amplify the noise.

Kaff can be calculated by following function:

ACC_%= 6746518 / K_Acc_FF / Easy_Kload * 100

ACC_% This means what percentage will be used for acceleration feedforward.

K_Acc_FF Kaff(60FB.03), calculates the final internal factor of the feedforward.

Easy_Kload Inertia Coefficient in Easy Mode (3040.07) Load coefficient calculated from auto-tuning or

direct user input inertia ratio.

Step 4:Smooth filter adjustment

The smoothing filter is a moving average filter. It filters the velocity commands from the

velocity generator to make the velocity and position commands smoother. Using this filtering

causes velocity and position commands to be delayed in the drive. So for some applications,

like CNC, it is better not to use this filter, but to do the smoothing in the CNC.

Smoothing filters reduce machine influence by smoothing commands. Smoothing Filter

(60FB.05) defines the time constant of this filter in ms. Under normal circumstances, if the

machine system vibrates when starting and stopping, it is recommended to increase the

smoothing filter setting.

Loading...

Loading...