9.3.6 Lower crankcase

1.

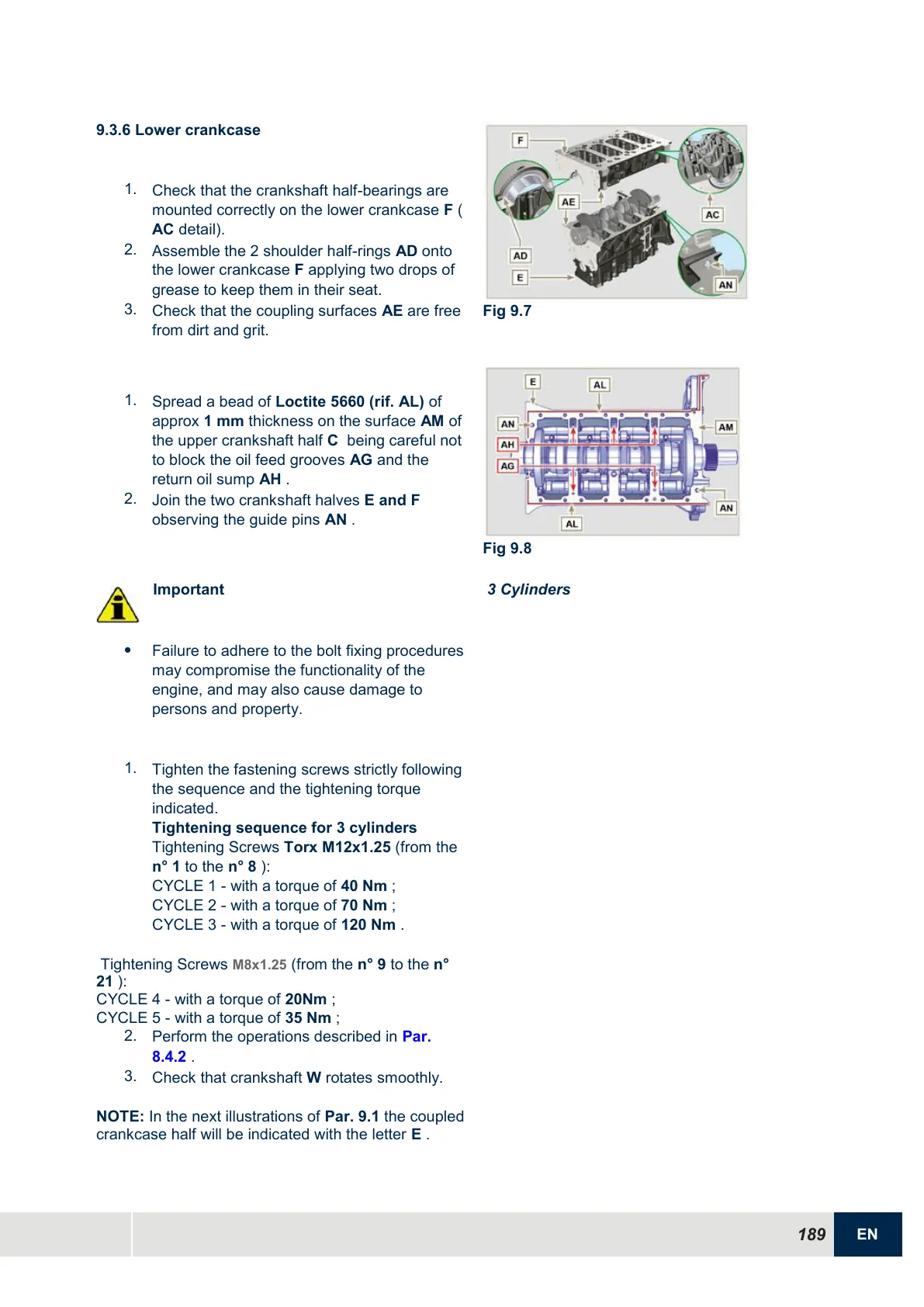

Check that the crankshaft half-bearings are

mounted correctly on the lower crankcase F (

AC detail).

2.

Assemble the 2 shoulder half-rings AD onto

the lower crankcase F applying two drops of

grease to keep them in their seat.

3.

Check that the coupling surfaces AE are free

from dirt and grit.

1.

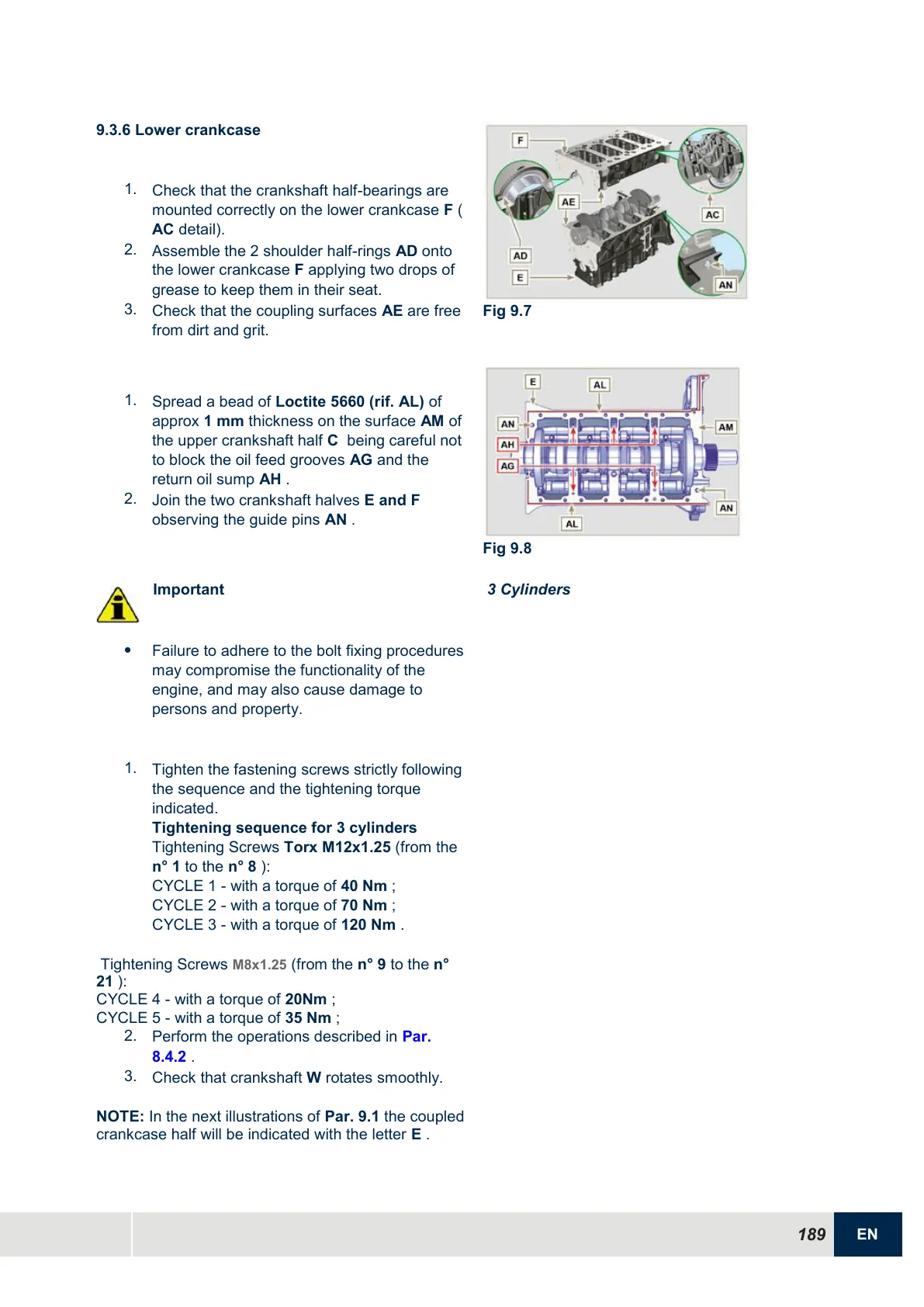

Spread a bead of Loctite 5660 (rif. AL) of

approx 1 mm thickness on the surface AM of

the upper crankshaft half C being careful not

to block the oil feed grooves AG and the

return oil sump AH .

2.

Join the two crankshaft halves E and F

observing the guide pins AN .

Important

Failure to adhere to the bolt fixing procedures

may compromise the functionality of the

engine, and may also cause damage to

persons and property.

1.

Tighten the fastening screws strictly following

the sequence and the tightening torque

indicated.

Tightening sequence for 3 cylinders

Tightening Screws Torx M12x1.25 (from the

n° 1 to the n° 8 ):

CYCLE 1 - with a torque of 40 Nm ;

CYCLE 2 - with a torque of 70 Nm ;

CYCLE 3 - with a torque of 120 Nm .

Tightening Screws M8x1.25 (from the n° 9 to the n°

21 ):

CYCLE 4 - with a torque of 20Nm ;

CYCLE 5 - with a torque of 35 Nm ;

2.

Perform the operations described in Par.

8.4.2 .

3.

Check that crankshaft W rotates smoothly.

NOTE: In the next illustrations of Par. 9.1 the coupled

crankcase half will be indicated with the letter E .

Loading...

Loading...