DETAILED CONTROLS AND GAUGES OPERATION

3-82

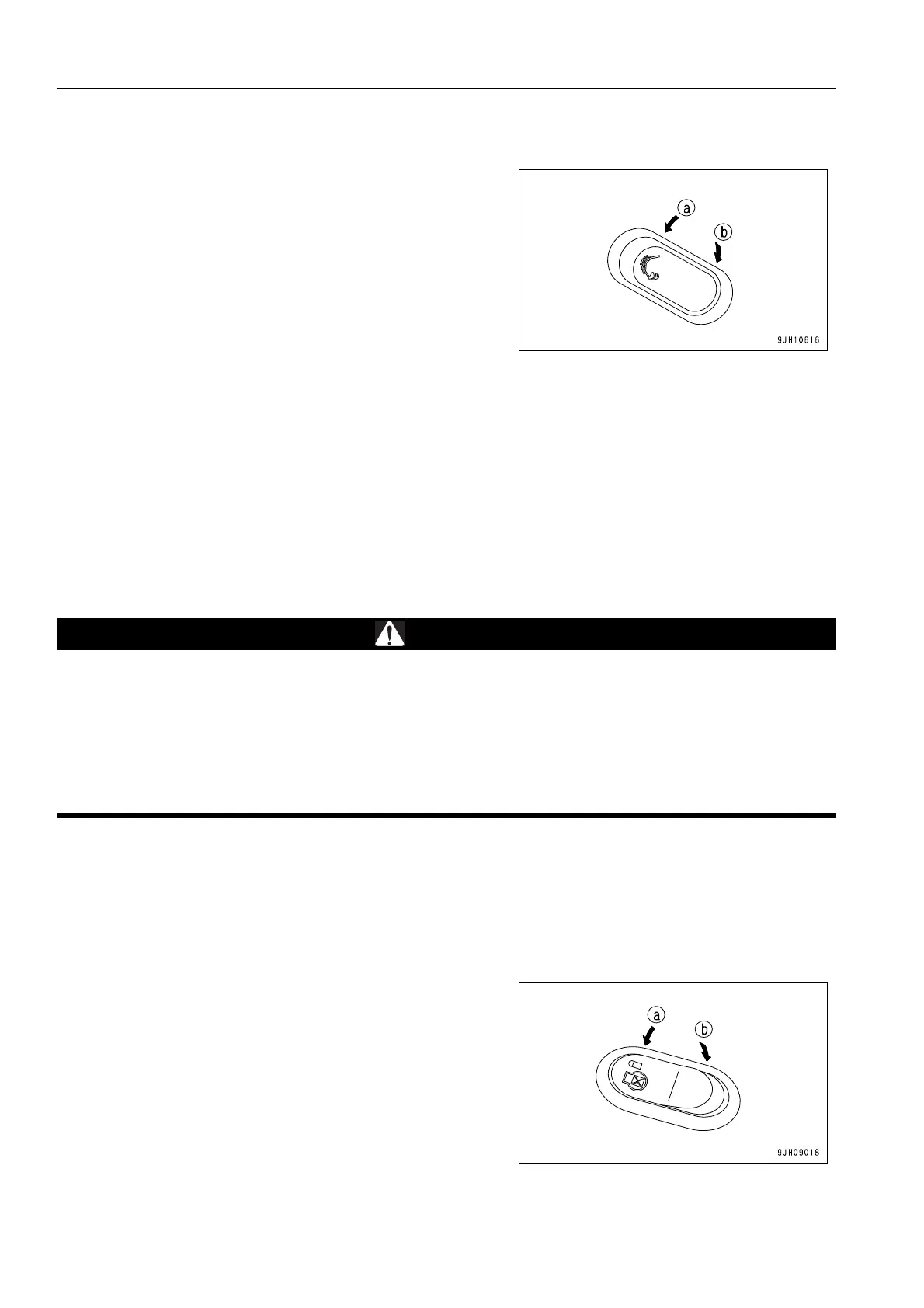

Boom Shockless Control Switch

Use this switch (14) to reduce the shaking of the work equip-

ment when the boom is stopped.

(a): ON

(b): OFF

Effect

q The shaking and spillage of load from the bucket is

reduced.

q Operator fatigue is reduced when operating for long peri-

ods, so operations can be performed saftely.

When this switch is ON, if the boom is stopped, the distance for

the boom to stop is slightly extended. Operate with care until

you become accustomed to it.

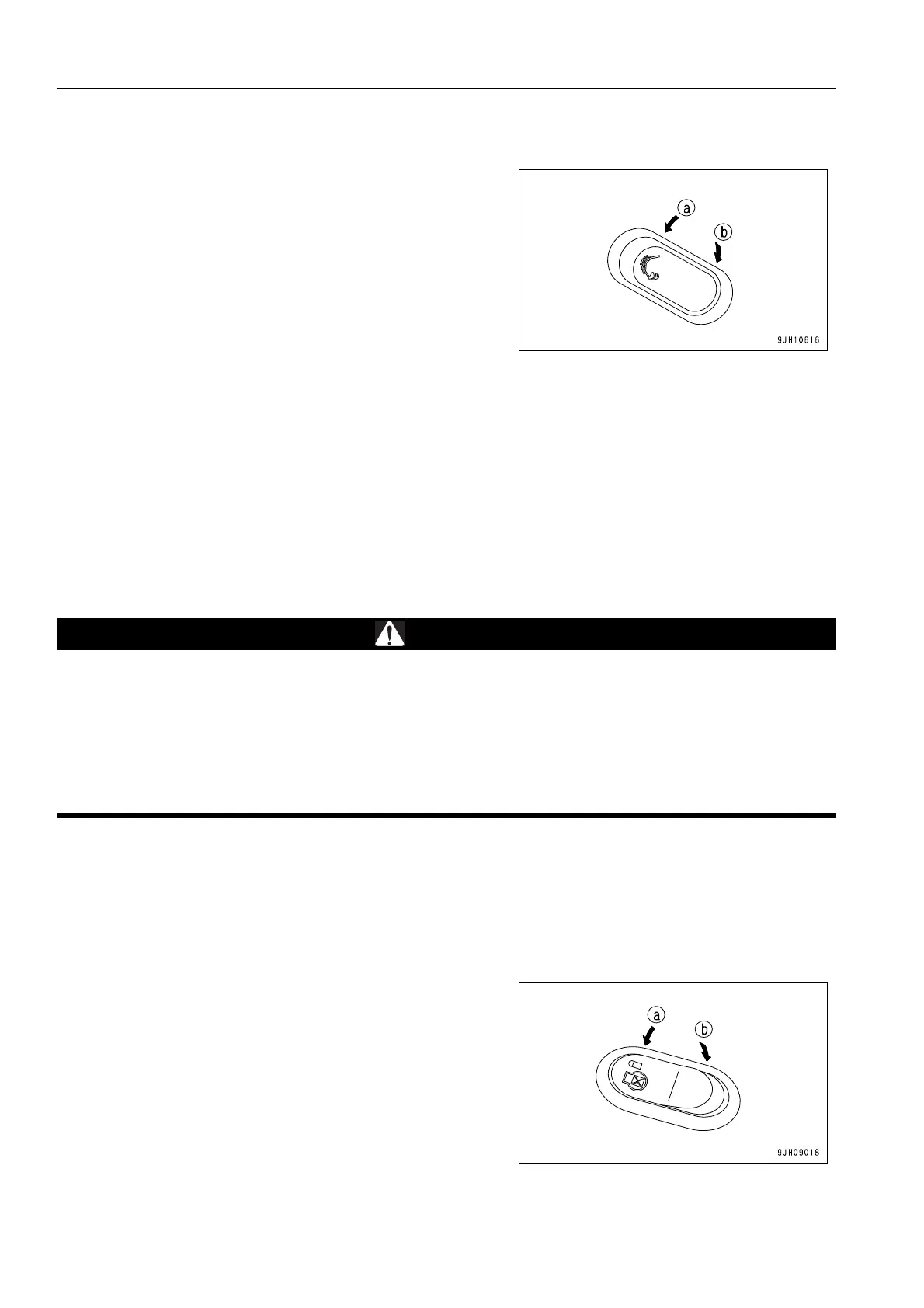

Swing Lock Switch

q Use this switch to lock the swing when not carrying out swing operations, such as when traveling.

q Be careful when operating on slopes. The load of the work equipment may cause the work equipment

to swing downhill if the swing control lever is operated, even when the swing lock switch is at the ON

position.

q If the swing control lever is operated immediately after setting the swing lock switch to the ON posi-

tion, swing drag may occur. To avoid danger, wait for approx. 5 seconds after turning the swing lock

switch to the ON position when relieving the swing circuit, such as during the warming-up operation.

While the machine is swinging, never operate the swing lock switch or stop the engine.

Such a practice can cause damage to the swing motor disc.

Use this switch (15) to lock the upper structure and prevent it

from rotating.

(a) ON position: The swing lock is always applied, so the upper

structure will not swing even if the swing is operated. When the

swing lock switch is ON, the swing lock monitor lights up.

(b) OFF position: The swing lock is actuated only when all work

equipment control levers are at Neutral. If any work equipment

control lever is operated, the swing lock is cancelled. The

swing lock is actuated approx. 10 seconds after all the work

equipment control levers are placed at Neutral.

Loading...

Loading...