59

CAUTIONS DURING WELDING REPAIR

Weld in a location with good facility, and, only authorized personnel are permitted to weld.

Unauthorized personnel are strictly prohibited since risks such as gas generation, fire and

electrical shock are present when welding.

The personnel authorized to weld are requested to always observe the following.

• Disconnect the battery terminals to prevent battery explosions.

• Peel off the paint from the welding section to prevent gas generation.

• Attempt to heat up a hydraulic machinery, piping or a section near such parts may cause

combustible vapor or mist to be generated and catch fire. Avoid heating such section.

• Directly heating a pressurized piping or rubber hose may cause a sudden snip. Apply a fire

protection cover.

• Disconnect the electro-tap connectors of the remote control system receiver, controller, and

monitor.

• Wear protective equipment.

• Always ventilate the area.

• Keep combustibles away from the area and prepare a fire extinguisher.

• Do not ground to a location near electrical part. Such may cause the electrical part to

malfunction.

DISCONNECT BATTERY TERMINAL

Disconnect (-) terminal of the battery and stop the electrical

flow before repairing the electrical system or starting an

electrical weld.

See “OPERATION 9. HANDLING BATTERY” for details.

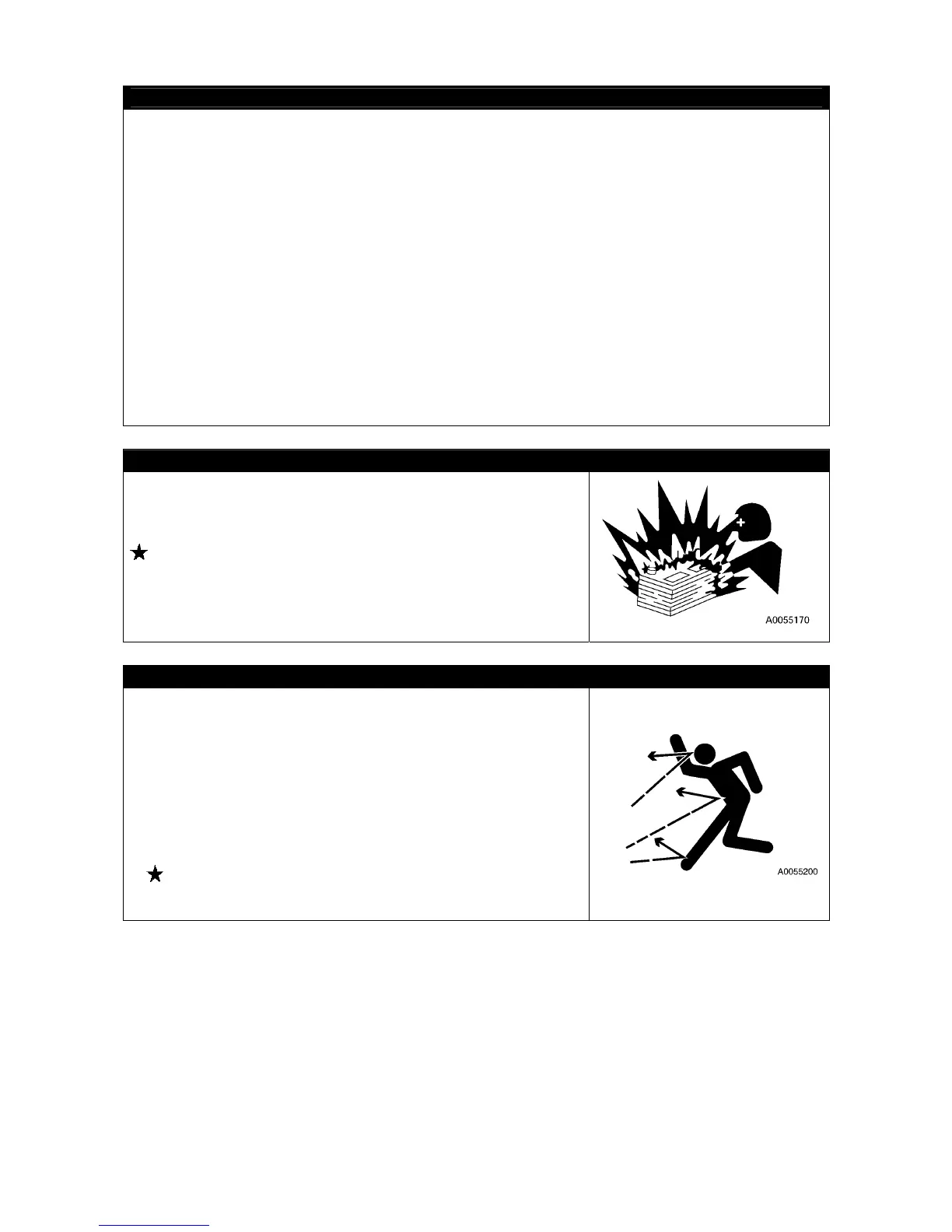

CAUTIONS WHEN ADJUSTING CRAWLER TENSION

• Grease is sealed inside the crawler tension adjuster. The

grease is at a high pressure because of the tension of the

crawler. Attempt to release the grease without observing the

following precautions may cause the grease valve to pop out

and result in serious accident.

• Do not loosen the tension adjustment grease valve one full

turn or above. Doing so may cause the grease valve to pop

out.

• To avoid the risk during tension adjustment, do not place

your body in front of the grease valve.

See “INSPECTION AND MAINTENANCE 9.2 [1]

INSPECTION/ADJUSTMENT OF RUBBER TRACK

TENSION”.

Loading...

Loading...