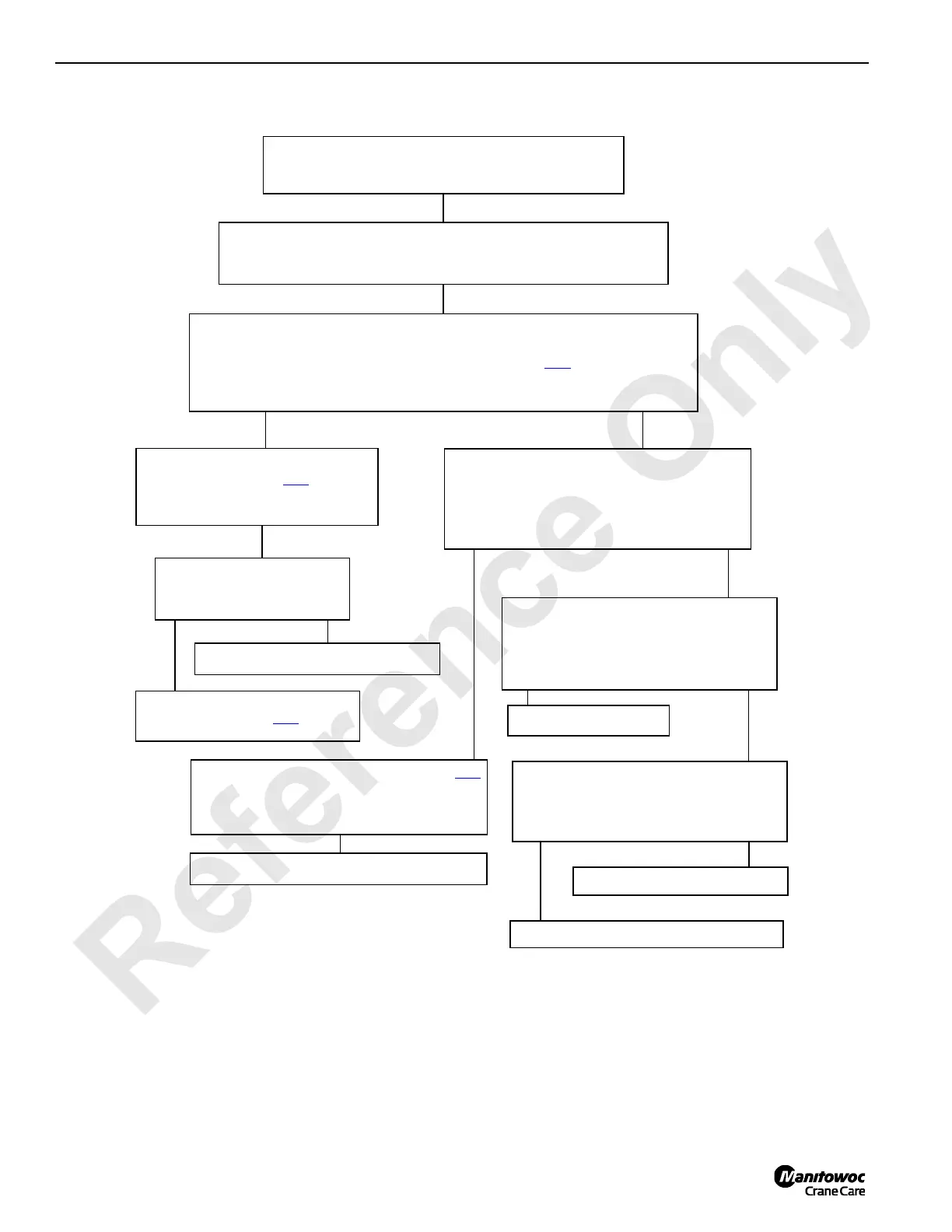

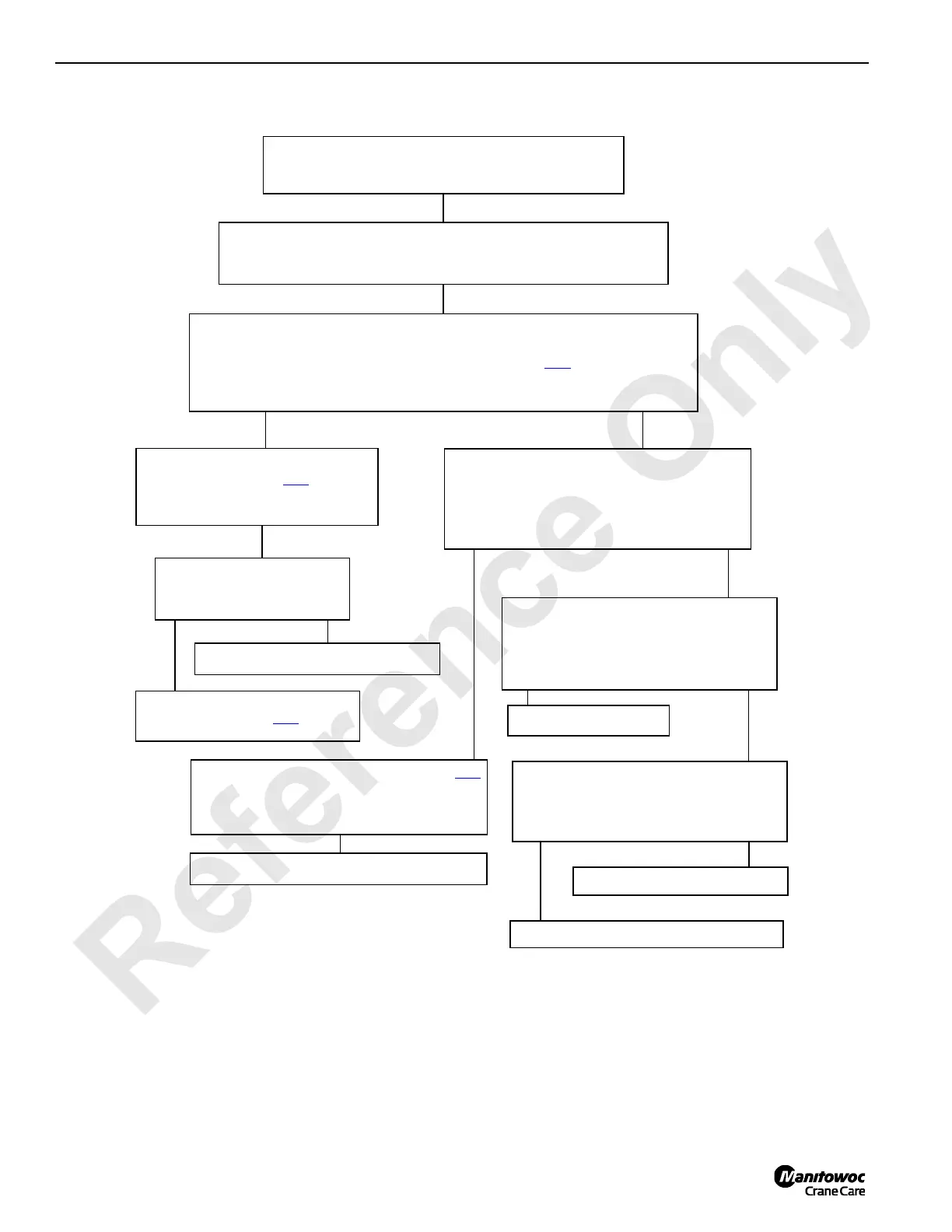

CHECKS

Check for 3,500 psi pressure at auxiliary system disable valve while enabling

any upper valve assembly components. (See Te st

25.)

PROBLEM 32

Upper and lower valve cylinders are not operating.

POSSIBLE CAUSES

Faulty relief valve, auxiliary system disable valve or switch or wiring. Fan

circuit component failure; Pump is bad; Wiring problem.

3,500 psi or less

3,500 psi or more

300 psi or less

Check pressure at pilot/brake pressure

relief valve. (See Tes t

24.)

Are fan impellers turning?

Yes No

Adjust or replace pilot/brake pressure

relief valve. (See Te st

24.)

Check fan circuit for component failure.

Adjust auxiliary system working pressure. (See Tes t

25.) Are cylinders operating correctly?

No

Repair or replace auxiliary system disable valve.

Enable any upper valve assembly component in

both directions and check that voltage is present

at auxiliary system disable valve.

Voltage

No Voltage

Yes

No

Does diagnostic display screen. D1 (bank 3)

change by 4 when enabling any auxiliary

system valve?

Repair or replace wiring.

Yes

No

Is crane set-up mode selected and confirmed at

operator display?

Replace fuse F13 or power switch or wiring.

Select and confirm set-up mode.

Loading...

Loading...