Manitowoc Published 11-06-15, Control # 040-13 1-47

2250 SERVICE/MAINTENANCE MANUAL INTRODUCTION

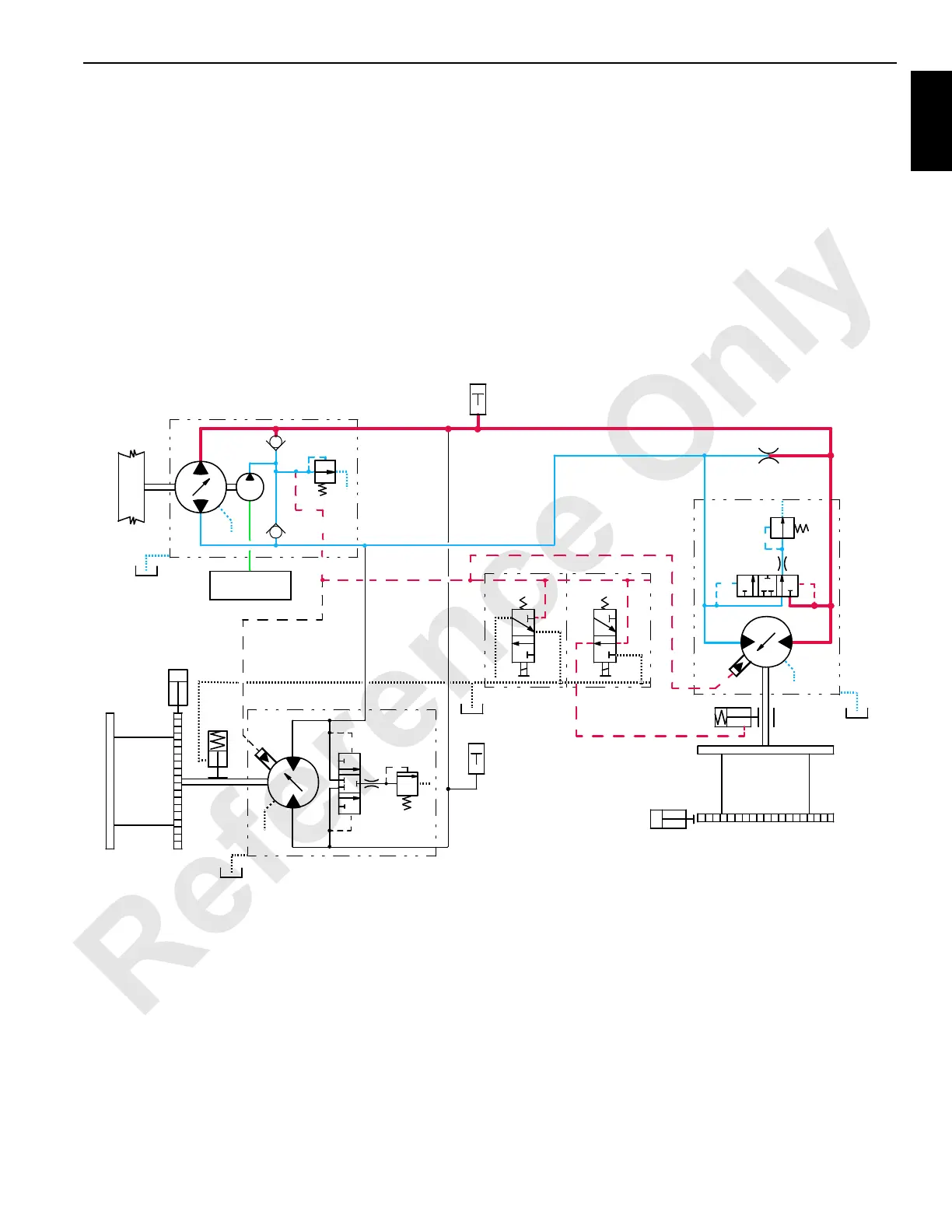

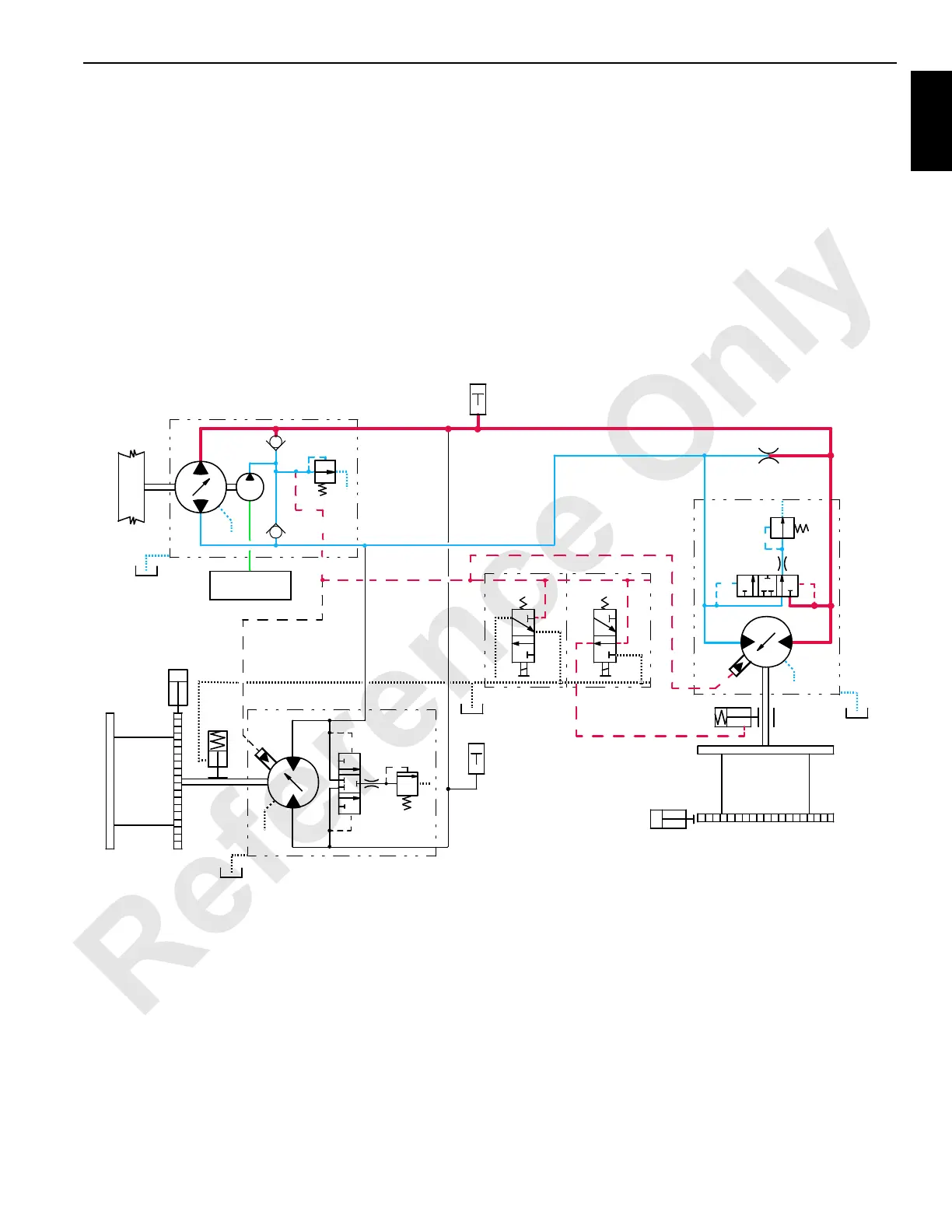

The PCOR valve over-rides the command from servo PC

valve, increasing motor displacement and output torque and

reducing output speed. When PCOR valve closes, control of

the motor returns to servo PC valve.

The PC is continuously balancing the system pressure and

the motor displacement angle so the motor displacement

goes to minimum when control handle is fully forward, if the

motor torque is not too high. The PC monitors motor

displacement and controls motor speed by regulating the

hydraulic fluid flow through the pump.

The weight of boom attempts to drive motor faster than

return fluid can return to low-pressure side of pump. System

charge pump maintains fluid supply at a positive pressure to

motor. Pump swashplate position restricts the returning fluid

flow. Pressure builds on fluid return side of closed-loop,

acting as a hydraulic brake to control lowering speed.

When boom hoist control handle is moved toward neutral

position, the PC compensates for hydraulic system leakage

or changing engine speed. The PC sends a 0 volt output to

pump EDC that moves swashplate to center position. This

shifts the motors back to maximum displacement for slower

output speed to slow the drum rotation.

The PC stores the boom holding pressure in pressure

memory. After control handle center switch opens, The PC

sends a 0 volt output to disable brake solenoid valve HS-6.

Drum brake solenoid valve shifts to block boom hoist charge

pump pilot pressure to brakes and opens a line to tank.

Brake applies before drum pump de-strokes.

HS-6

RF-18

DRUM

SUCTION

MANIFOLD

DOWN

UP

340 PSI

(23 BAR)

A

B

BOOM HOIST/LUFFING JIB PUMP

.060

PILOT

BOOM HOIST

BRAKE

A

275 PSI

(19 BAR)

B

AIR PAWL

CYLINDER

PRESSURE

SENDER

HS-19

DRUM

BRAKE

A

277 PSI

(19 BAR)

B

SERVO

LUFFING

JIB

AIR PAWL

CYLINDER

(SEE FIGURE 18)

PRESSURE

LUFFING JIB MOTOR

BOOM HOIST MOTOR

DOWN

UP

PRESSURE

SENDER

SERVO

FIGURE 1-26

Loading...

Loading...