Manitowoc Published 11-06-15, Control # 040-13 1-67

2250 SERVICE/MAINTENANCE MANUAL INTRODUCTION

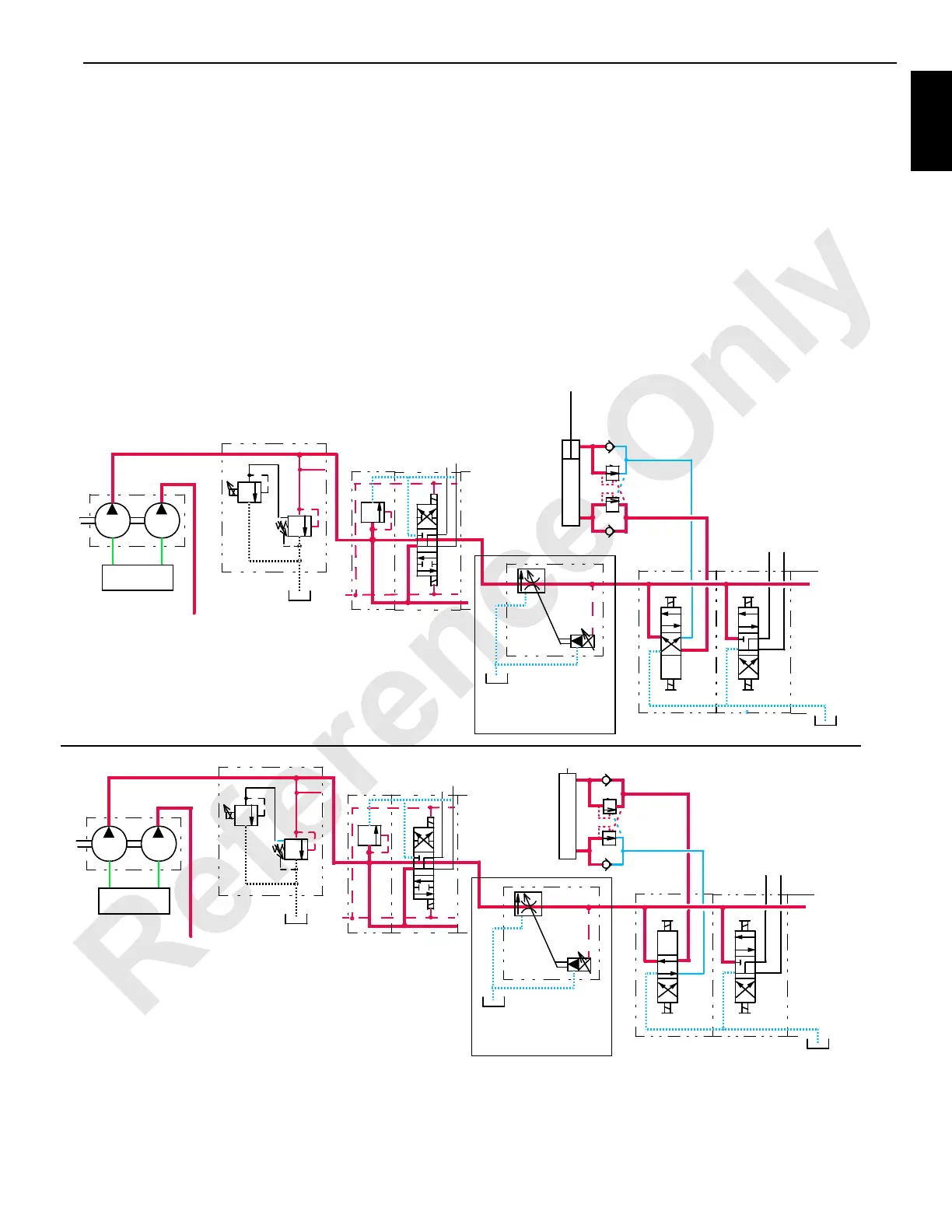

Boom Butt Handling Cylinder Retract

When power button is pressed and boom butt cylinder switch

is held in the down retract position, an input signal is sent to

the PC. The PC sends a 12 volt output signal to auxiliary

system disable relief valve HS-12 that adjust system

pressure to 3,500 psi (241 bar).

Boom butt cylinder engage solenoid HS-16 is enabled by the

PC to shift the solenoid valve in the retract position.

Hydraulic fluid enters upper accessory valve and flows

through variable output control valve HS-20 and hydraulic

quick disconnect assembly to the lower accessory valve.

Hydraulic fluid exits the valve assembly and flows through

the free-flow check valve section of counterbalance valve.

Hydraulic fluid then enters rod end of boom butt handling

cylinder, retracting the cylinder to lower the boom butt.

Fluid from piston end of cylinder is blocked by the opposite

side free-flow check valve section of counterbalance valve

and flows through the flow restraining section with a relief

setting of 3,000 psi (207 bar).

Counterbalance valve acts as a deceleration control with a

3:1 pilot ratio. Hydraulic fluid flows through boom butt

handling cylinder valve to tank through the hydraulic quick

disconnect.

When power button or boom butt cylinder switch is released,

the PC sends a 0 volt output to shift spool of solenoid HS-16

to center position.

BOOM BUTT HANDLING CYLINDER EXTEND

RF-35

AUXILIARY SYSTEM

SUCTION

MANIFOLD

RELIEF VALVE

HS-12

AUXILIARY PUMP

FAN PUMP

TO FAN

DISABLE

CIRCUIT

UPPER ACCESSORY VALVE

HS-16

HS-15

LOWER ACCESSORY VALVE

x

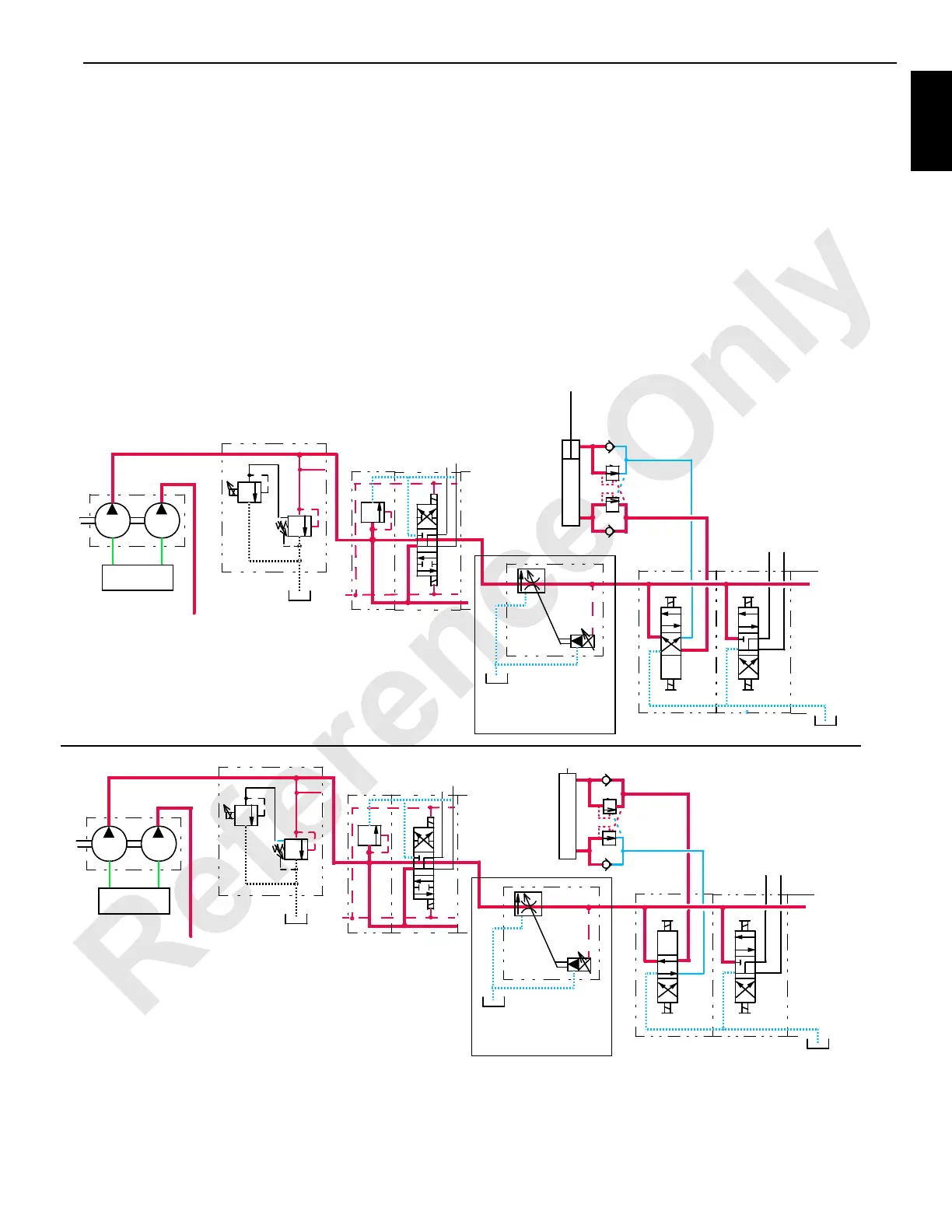

RF-36

AUXILIARY SYSTEM

SUCTION

MANIFOLD

RELIEF VALVE

HS-12

AUXILIARY PUMP

FAN PUMP

TO FAN

DISABLE

CIRCUIT

UPPER ACCESSORY VALVE

HS-16

HS-15

LOWER ACCESSORY VALVE

x

VARIABLE OUTPUT VALVE

0 TO 15 gpm (57 l/min)

VARIABLE OUTPUT VALVE

0 TO 15 gpm (57 l/min)

BOOM BUTT HANDLING CYLINDER RETRACT

X

X

FIGURE 1-39

(PAST PRODUCTION)

(PAST PRODUCTION)

Loading...

Loading...