Fd

THE

AUTOMATIC GEARBOX

OPERATIONS

KEY

TO ACTION

1.

Check manual linkage

adjustment.

12.

Examine

rear

clutch,

check valve, and seals. Check ■t

2.

Check ■uid level.

of tubes.

3.

Check adjustment

of down-shift and

throttle

valve

13.

Strip and clean valve bodies.

cable,

using

line

pressure gauge

and

tachometer,

14.

Strip and clean

governor

valve.

4.

Reduce

engine

idle Speed.

15.

Examine

parking pawl,

gear,

and internal linkage.

5.

Check adjustment

of front

band.

16.

Examine

one-way

clutch.

6.

Check front

servo

seals and

fit of tubes.

17. Strip

and

examine

pump

and

drive

tangs.

7.

Check front band

for

wear.

18.

Strip and

examine

gear

train.

8.

Check adjustment

of

rear

band.

19.

Adjust

starter

inhibitor switch inwards.

9.

Check

rear

servo

seal and

fit of

tubes.

20.

Adjust

starter

inhibitor

switch outwards.

10.

Check

rear

band

for

wear.

21. Replace

torque converter.

11.

Examine

front clutch and seals, also

forward

sun gear

22.

Examine

torque converter

drive plate for cracks

or

shaft sealing

rings.

Verify that

cup

plug

in

driven shaft

fracture.

is

not

leaking

or

dislodged.

23.

Check

engine

performance.

Section

F

d.7

Starter inhibitor and

reverse

light switch

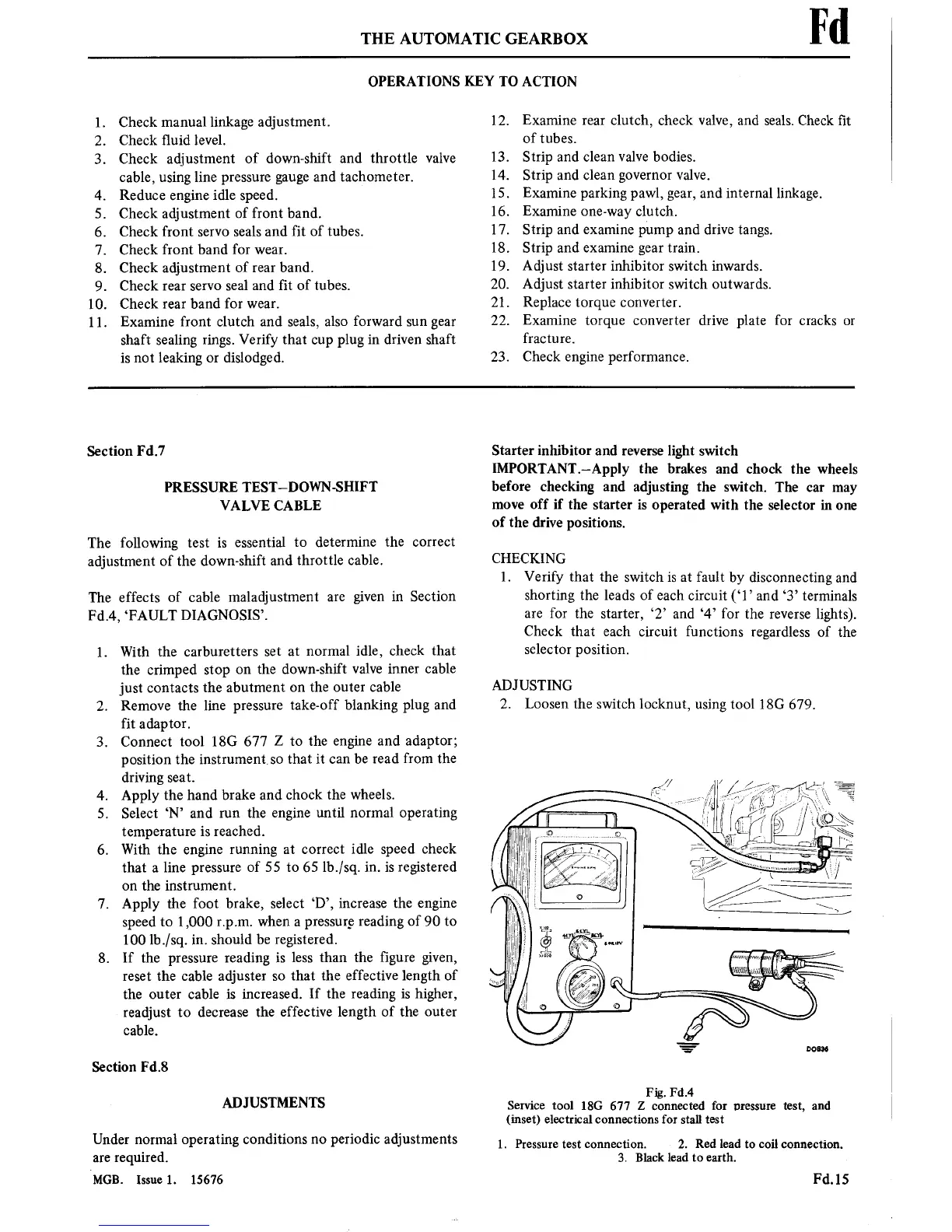

PRESSURE

TEST—DOWN-SHIFT

VALVE CABLE

The

following

test

is

essential

to

determine

the

correct

adjustment

of the

down-shift and

throttle cable.

The

effects

of

cable

maladjustment

are

given

in Section

Fd.4, ‘FAULT

DIAGNOSIS’.

1.

With the carburetters

set at

normal idle,

check that

the crimped

stop

on

the

down-shift

valve

inner

cable

just

contacts

the abutment

on

the

outer

cable

2.

Remove

the line

pressure

take-off blanking

plug and

fit adaptor.

3.

Connect

tool

18G

677

Z

to

the

engine

and adaptor;

position

the

instrument

so

that

it

can

be

read

from

the

driving

seat.

4.

Apply the hand

brake and chock the

wheels.

5.

Select

‘N’ and

run

the

engine

until normal

operating

temperature

is

reached.

6.

With

the

engine

running

at

correct

idle speed check

that

a

line

pressure

of

55

to

65

lb./sq.

in. is

registered

on

the

instrument.

7.

Apply the foot

brake, select ‘D’,

increase

the

engine

speed

to

1,000

r.p.m.

when

a

pressure

reading of

90

to

100

1b./

sq.

in.

should be

registered.

8.

If the

pressure

reading

is

less than

the figure

given,

reset

the cable adjuster

so

that the

effective length of

the

outer

cable

is

increased.

If the

reading

is

higher,

readjust

to

decrease

the effective length

of

the

outer

cable.

Section

Fd.8

ADJUSTMENTS

Under

normal

operating

conditions

no

periodic adjustments

are

required.

SMGB.

Issue1.

15676

IMPORTANT—Apply the brakes

and

chock

the wheels

before checking

and

adjusting the switch. The

car may

move

off

if the

starter

is operated

with the selector

in

one

of

the drive

positions.

CHECKING

1.

Verify that the

switch

is

at

fault

by disconnecting

and

shorting the

leads

of

each

circuit

(‘1’

and ‘3’ terminals

are

for the

starter,

‘2’

and ‘4’

for

the

reverse

lights).

Check

that each

circuit

functions

regardless

of

the

selector

position.

ADJUSTING

2. Loosen the switch locknut,

using

tool 180

679.

Fig. Fd.4

Service

tool 18G 677

Z

connected for

pressure

test,

and

(inset) electrical connections

for

stall

test

1.

Pressure

test

connection. 2.

Red lead

to

coil

connection.

3. Black lead

to

earth.

Fd.15

Loading...

Loading...