7 - 3

7.1 Power Supply Wiring

7.1.2 The cause of malfunctions related wiring/Remedy

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

PART NAME

5

EMC DIRECTIVE

6

INSTALLATION

7

WIRING

8

OPTION

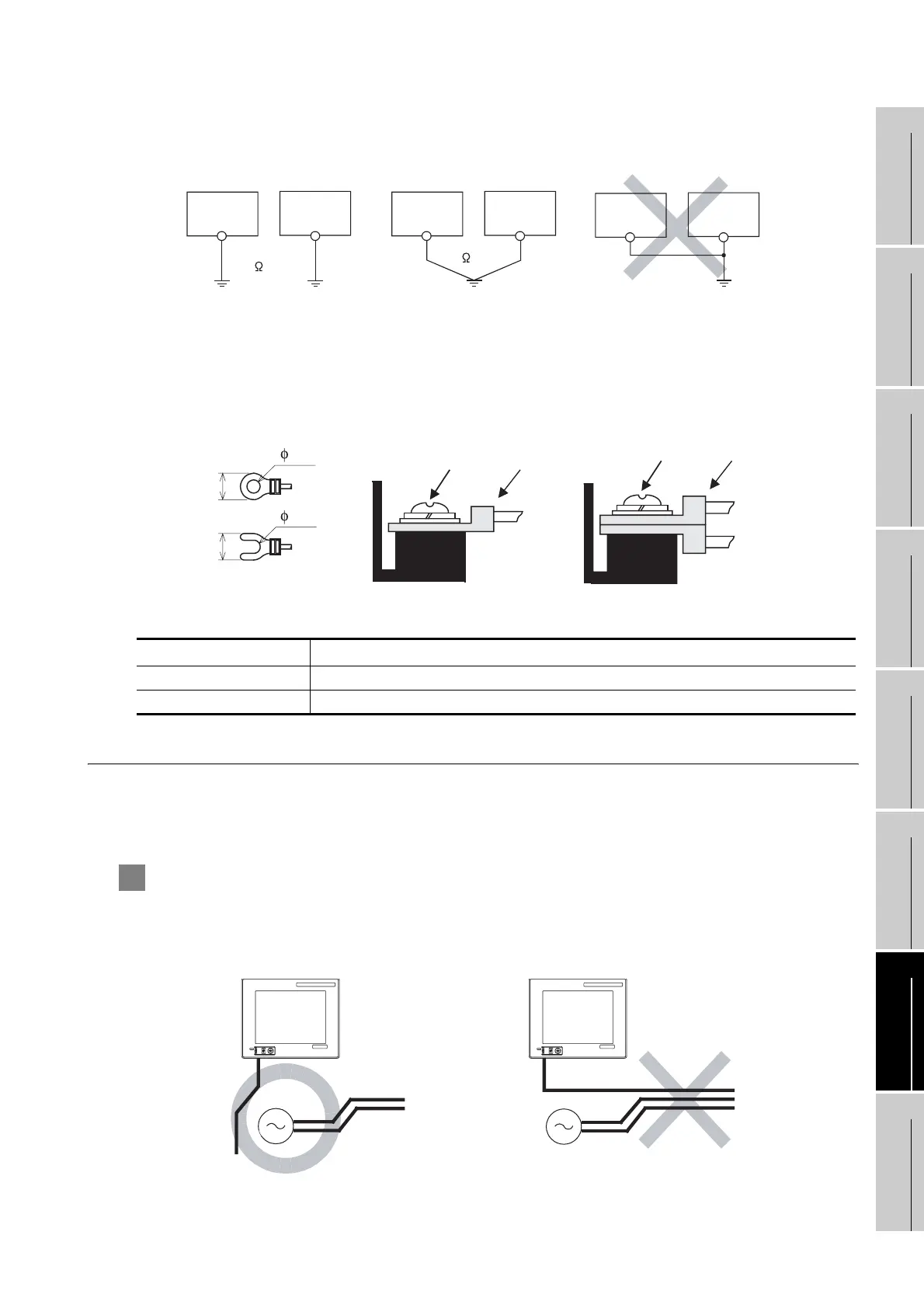

Make sure to carry out the followings for grounding.

• Carry out the independent grounding if possible.

• If the independent grounding is impossible, carry out the shared grounding as shown in fig.2) below.

• Use the cable of 2mm

2

or more for grounding.

Set the grounding point closer to the GOT to make the grounding cable short as possible.

Recommended terminal shape

7.1.2 The cause of malfunctions related wiring/Remedy

Grounding of the GOT may cause electric potential difference and noise interference, which may result in

GOT malfunctions.

These problems may be resolved by taking the following measures.

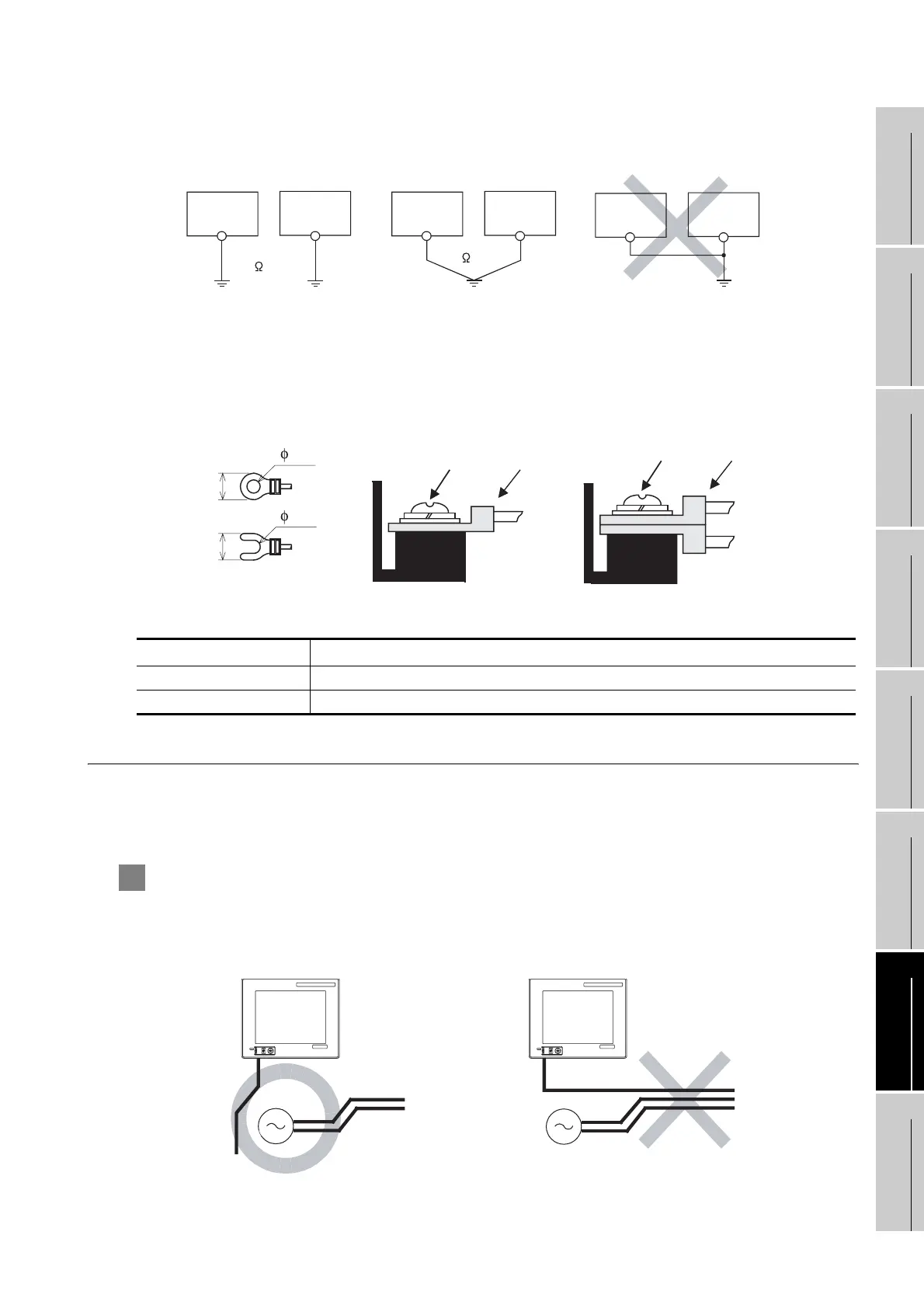

1 Wiring path of the GOT's ground cable and power line

Bundling the GOT's ground cable and power line together can cause interference noise, which may

result in malfunctions.

Keeping the GOT's ground cable and power line away from each other will help minimize noise

interference.

Cable size

For power supply: 0.75mm

2

min. For grounding: 2mm

2

min.

Solderless terminal M3 solderless terminal (applicable solderless terminal: RAV 1.25-3, V2-N3A and FV2-N3A)

Tightening torque 0.5 to 0.8N•m

GOT

Other

device

(1) Independent ground

...... Best condition

GOT

Other

device

(2) Shared grounding

...... Good condition

GOT

Other

device

(3) Common grounding

...... Not allowed

Grounding

(100 or less)

Grounding

(100 or less)

Terminal

screw

Solderless

terminal

Terminal

screw

6.2mm

or less

3.2

3.2

6.2mm

or less

When wiring one cable to

one terminal

When wiring two cables to

one terminal

Solderless

terminal

FG

Power supply for power equipment

Good : Wiring the ground cable away from the

power cable

FG

Power supply for power equipment

Bad : Bundling the ground cable and

the power cable

GRAPHIC OPERATION TERMINAL

GOT

1000

MITSUBISHI

GRAPHIC OPERATION TERMINAL

GOT

1000

MITSUBISHI

Loading...

Loading...