6-50

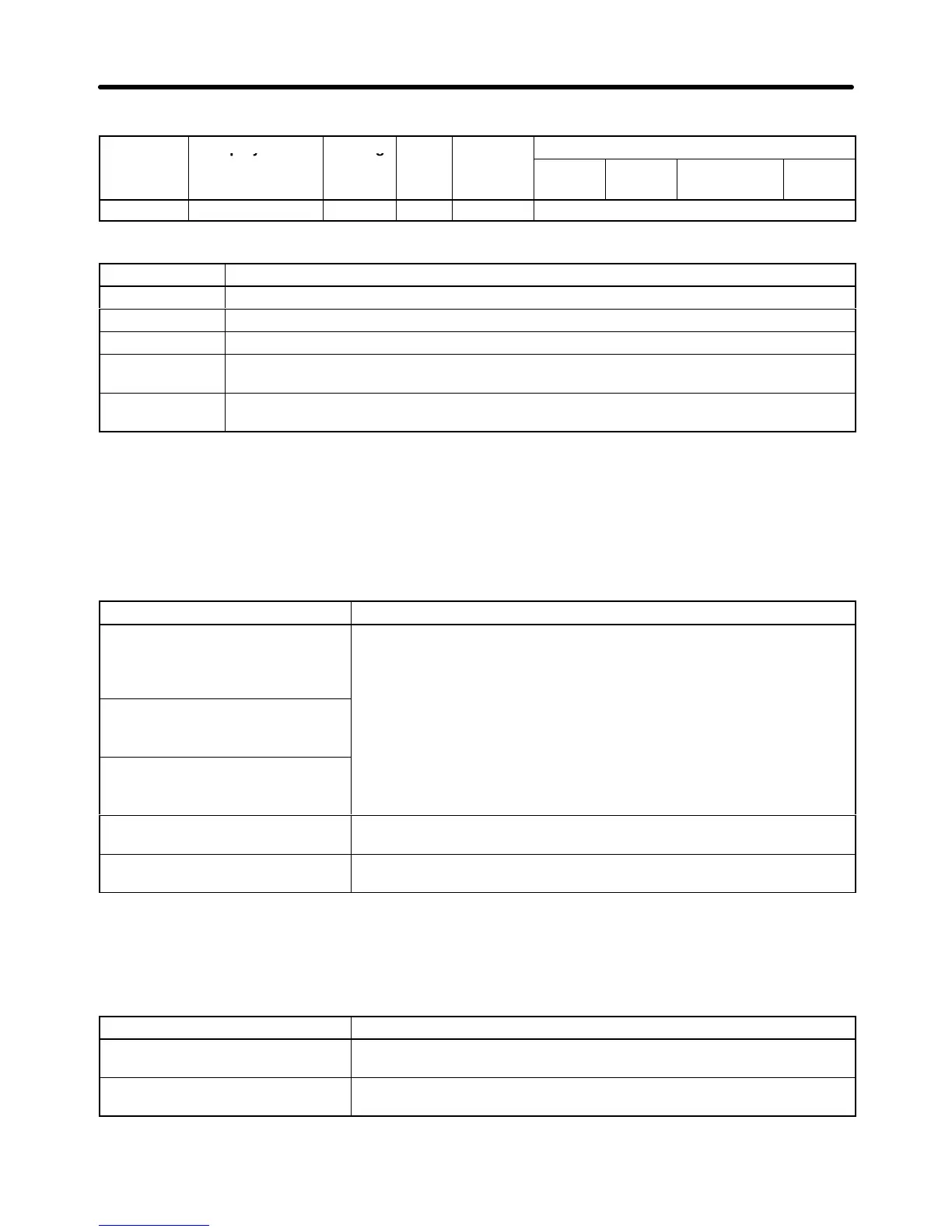

D PID Control Settings

Parameter Display name Setting Units Default

Valid access levels

number

range setting

V/f

Control

V/f with

PG

Open Loop

Vector

Flux

Vector

b5-01 PID Mode 0 to 4 --- 0 Advanced

This parameter cannot be changed during operation.

Set value Contents

0 PID disabled

1 PID enabled (Deviation signal is put through derivative control.)

2 PID enabled (Feedback signal is put through derivative control.)

3 PID enabled. (Frequency reference and PID control/deviation signal are put through

derivative control.)

4 PID enabled. (Frequency reference and PID control/feedback signal are put through

derivative control.)

Note 1. To

enable PID control, set 1 through 4. (Normally 2 or 4 is used for measured-value derivative

PID control.)

Note 2. If

the target speed of the application (e.g., tension control) is rather

clear and PID control is

required for fine tuning, set 3 or 4 for frequency reference and PID control.

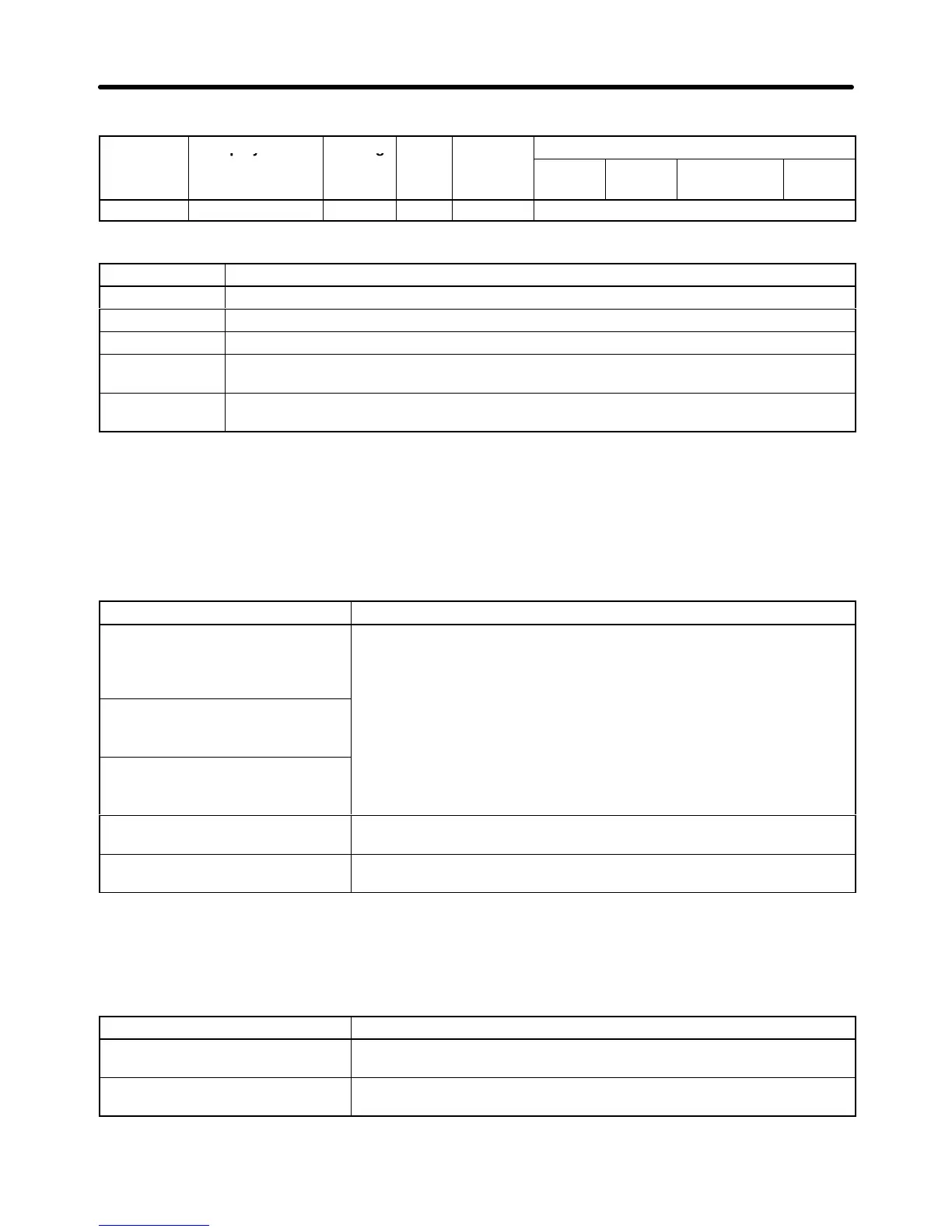

Setting Target Values for PID Control

The following guidelines can be used to select target values for PID Control.

c Contents

Frequency reference input,

voltage: Terminal 13

The frequency source selected for parameter b1-01 is used as the

target value.

Note 1. If

the PID control target value is not set for a multi-function ana

-

lo

Setting via Digital Operator

,

H3-09), then the setting of b1-01 is used automatically.

Note 2. Frequency references 2 to 8 and the inching reference are

enabled regardless of the setting of b1 01

Option frequency reference

ena

.

Note 3. Operation

will be clearer if o1-03 is set to 1 (% unit) when set

-

ting from a Digital Operator.

Multi-function analog input:

Terminal 16

Set C for the function selection of multi-function analog input terminal

16 (H3-05) to select the PID target value.

Frequency reference, current:

Terminal 14

Set C for the function selection of frequency reference (current)

terminal 14 (H3-09) to select the PID target value.

Note When using different input signals for frequency reference and PID control, set the PID target

value to either a multi-function analog input or the frequency reference (current).

Setting Feedback Values for PID Control

The following guidelines can be used to select feedback values for PID Control.

c Contents

Multi-function analog input:

Terminal 16

Set B for the function selection of multi-function analog input terminal

16 (H3-05) to select the PID feedback value.

Frequency reference, current:

Terminal 14

Set B for the function selection of frequency reference (current)

terminal 14 (H3-09) to select the PID feedback value.

Note 1. Use the gain and bias settings for the analog inputs to adjust the feedback value.

Advanced Operation Chapter

6

Loading...

Loading...