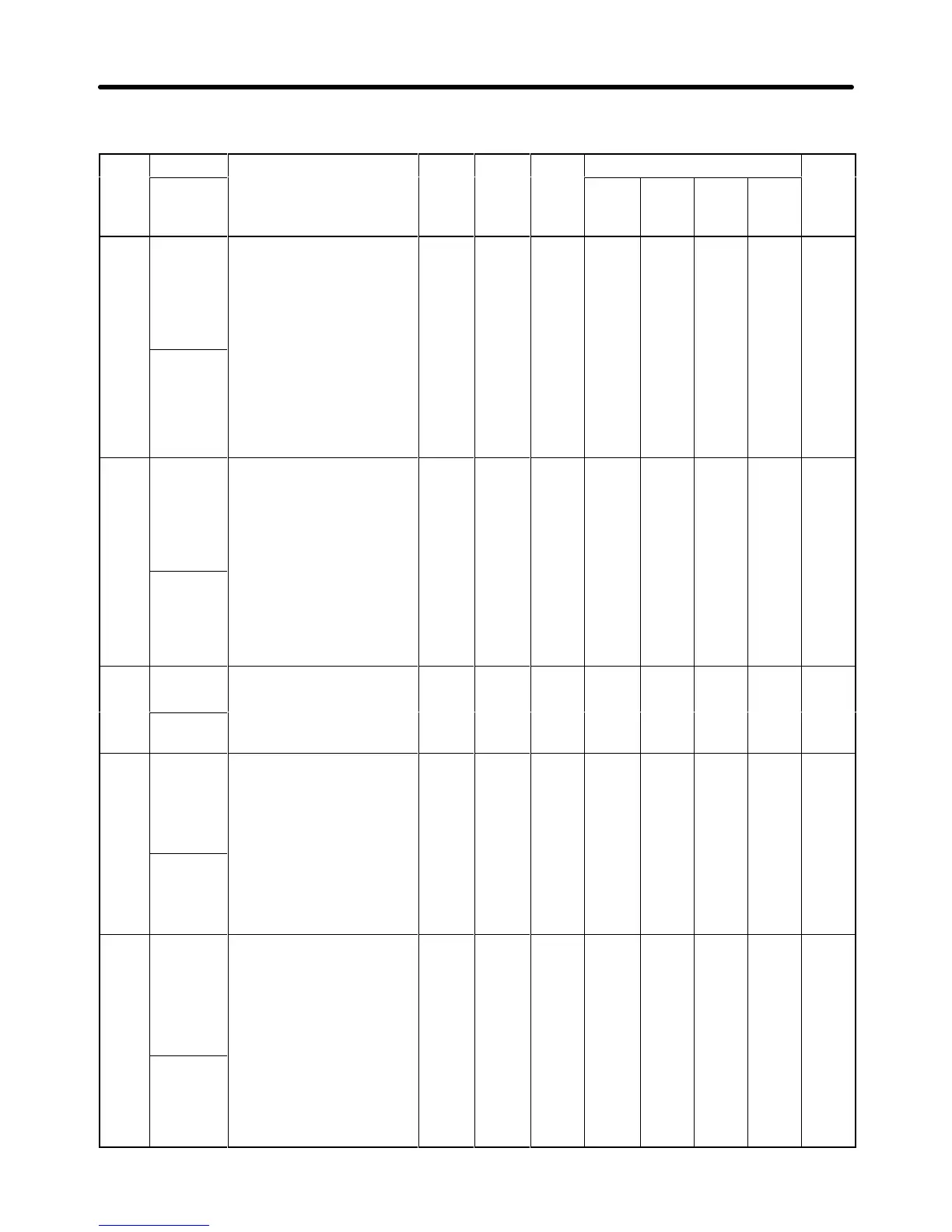

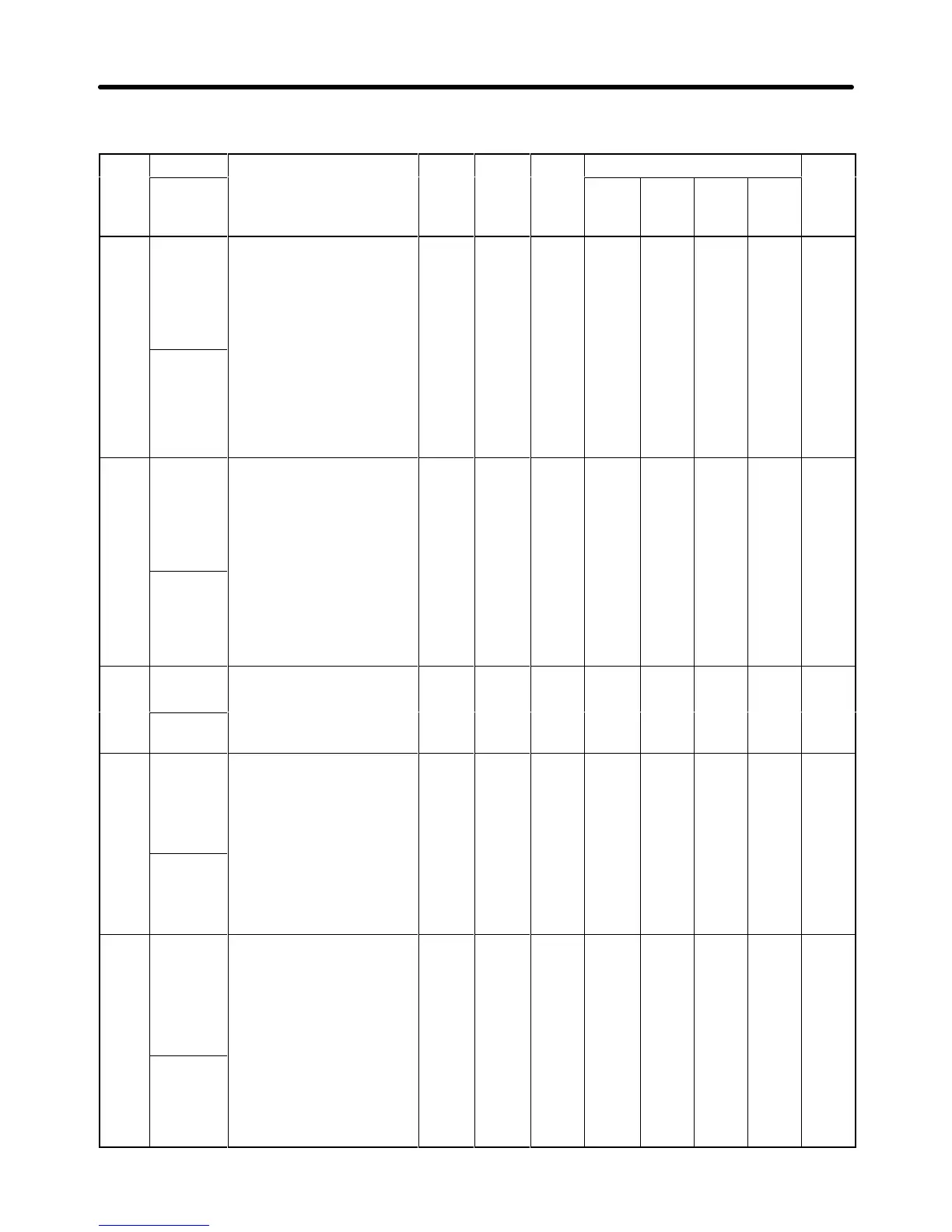

7-15

H Motor-Slip Compensation: C3

Para

Control

mode

Page

meter

No.

Display

name

range setting ges

during

opera-

tion

V/f

control

V/f

with

PG

Open

loop

vector

Flux

vector

C3-01

Slip com

-

pensation

gain.

Used to improve speed

accuracy when operating with a

load.

Note:

Usually setting is not nec

-

essary

.

When actual speed is low

,

increase the set value.

When actual speed is

0.0 to

2.5

1.0

(See

note.)

OK B X B B 6-59,

6-34

Slip Comp

Gain

high, decrease the set

value.

In flux vector control

mode this function be

-

comes gain to compen

-

sate for slip caused by

temperature variation.

C3-02

Slip com

-

pensation

primary

delay time.

Slip compensation primary

delay time is set in ms units.

Note:

Usually setting is not nec

-

essary.

Adjust when slip com

-

pensation responsiveness

is low

, or speed is not sta

-

bilized.

0 to

10000

200

(See

note.)

NO A X A X 6-59

Slip Comp

Time

.

When responsiveness is

low

, decrease the set val

-

ue.

When speed is not stabi

-

lized, increase the set val

-

ue.

C3-03

Slip com

-

pensation

limit.

Sets the slip compensation limit

as a percentage of motor rated

slip.

0 to

250

200 NO A X A X 6-60

Slip Comp

Limit

C3-04

Slip com

-

pensation

during re

-

generation.

0: Disabled.

1: Enabled.

Note:

When the slip compensa

-

tion during regeneration

function has been acti

-

vated, as regeneration ca

-

pacit

increases momen

-

0, 1

0 NO A A A X 6-60

Slip Comp

Regen

-

tarily, it may be necessary

to use a braking option

(braking resistor

, Braking

Resistor Unit or Braking

Unit.)

C3-05

Flux Cal

-

culation

Method

Used to set the flux calculation

method. Normally

, this setting is

not required.

0:

Flux is calculated based on

the output frequency after

frequencies using slip

compensation, etc.

1:

Flux is calculated based on

0, 1

0 NO X X A X 6-6

Flux Select

ore

correcting frequencies using

slip compensation, etc.

Note:

Set to “1” when motor

rotation becomes unsta

-

ble due to interference

using slip compensation.

Parameter Lists Chapter

7

Loading...

Loading...