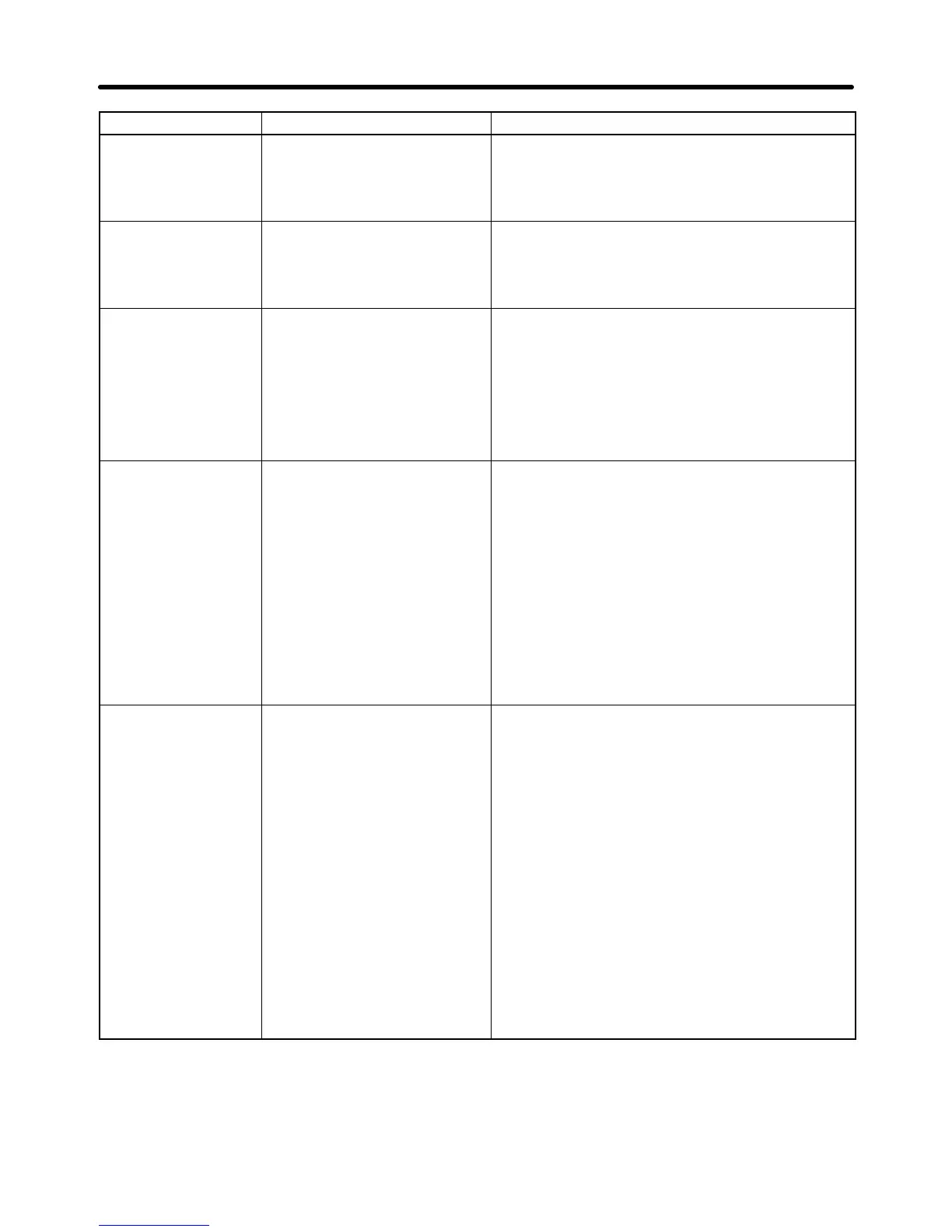

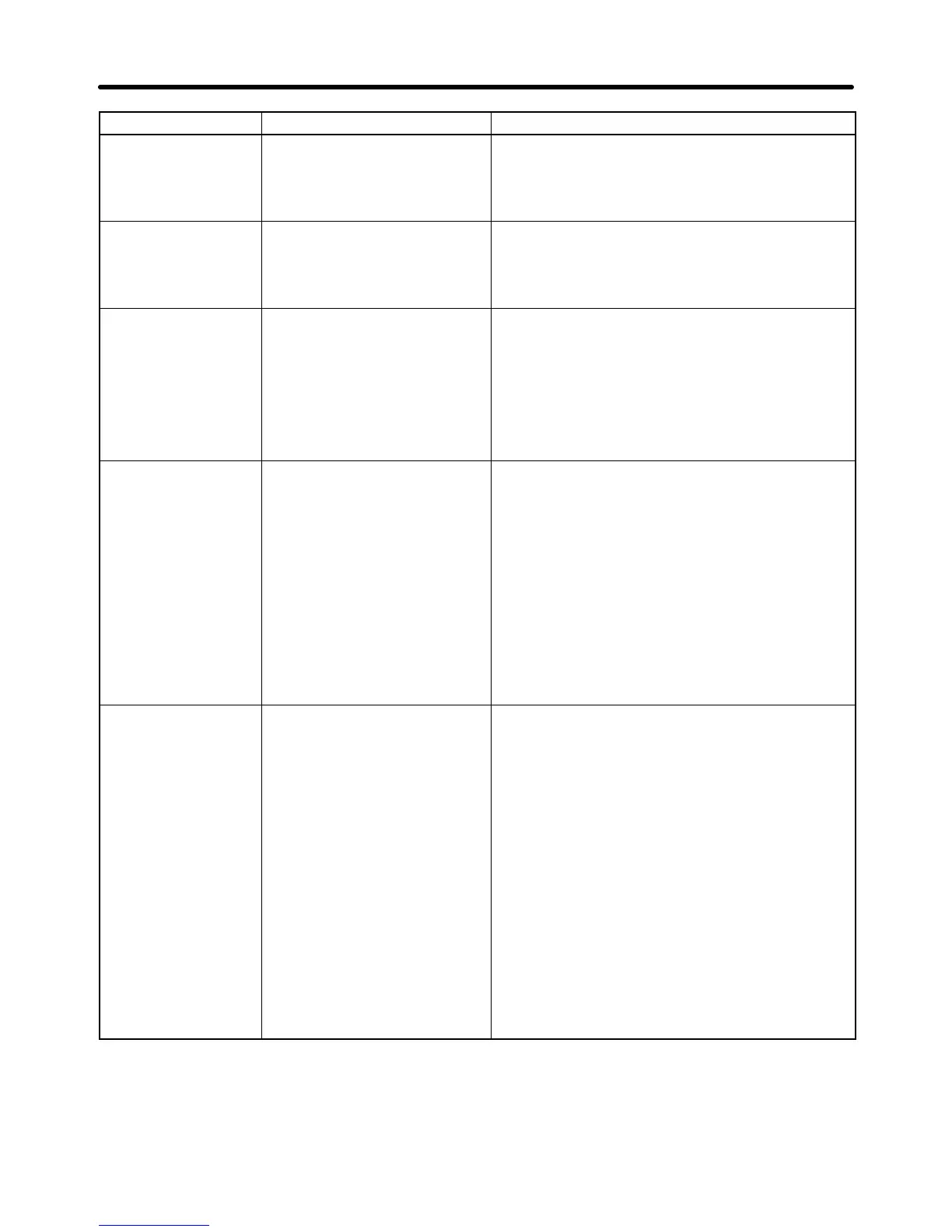

8-5

Fault Display Probable causes and remediesMeaning

OL3

Overtorque Det 1

There has been a current

greater than the setting in

L6-02 for longer than the

setting in L6-03.

→ Make

sure

that the settings in L6-02 and L6-03

are appropriate.

→ Check the mechanical system and correct the

cause of the overtorque.

OL4

Overtorque Det 2

There has been a current

greater than the setting in

L6-05 for longer than the

setting in L6-06.

→ Make

sure that the current setting in L6-05 and

time setting in L6-06 are appropriate.

→ Check the mechanical system and correct the

cause of the overtorque.

OS

Over speed

The speed has been greater

than the setting in F1-08 for

longer than the setting in

F1-09.

• Overshooting/Undershooting are occurring.

→ Adjust the gain again.

• The reference speed is too high.

→ Check

the

reference circuit and reference gain.

• The

settings in F1-08 and F1-09 aren’t

appropriate.

→ Check the settings in F1-08 and F1-09.

PGO

PG open

The PG is disconnected.

The Inverter is outputting a

frequency, but PG pulses aren’t

being input.

• The is a break in the PG wiring.

→ Fix the broken/disconnected wiring.

• The PG is wired incorrectly.

→ Fix the wiring.

• Power isn’t being supplied to the PG.

→ Supply power to the PG properly.

• The torque limit is set to 0 through CompoBus/D

communications. (Applies only to flux vector con-

trol.)

→ Set F9-05 to 0 (torque limit disabled).

DEV

Speed Deviation

The speed deviation has been

greater than the setting in

F1-10 for longer than the

setting in F1-11.

• The load is too large.

→ Lighten the load.

• The acceleration time and deceleration time are

too short.

→ Lengthen the acceleration time and decelera-

tion time.

• The load is locked.

→ Check the mechanical system.

• The

settings in F1-10 and

F1-1

1 aren’t appropriate.

→ Check the settings in F1-10 and F1-11.

• The torque limit is set to 0 through CompoBus/D

communications. (Applies only to flux vector con-

trol.)

→ Set F9-05 to 0 (torque limit disabled).

Maintenance Operations Chapter

8

Loading...

Loading...